Simulation research on flow field characteristics of atomizing nozzle by circular seam air impact

-

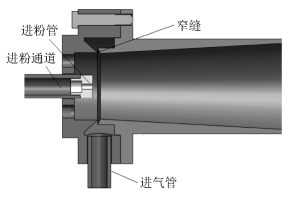

摘要: 分析了一种环缝气流冲击雾化制粉喷嘴的结构和工作原理, 并对该雾化喷嘴模型进行了流场分布数值仿真, 研究了不同进气压力和窄缝倾角对流场速度分布的影响。研究结果表明, 从进气管入口到气流冲击雾化喷嘴出口, 加速气流速度保持最大值不变, 在距进气管入口中心线上80 mm位置之后逐渐减小; 随着进气压力的增加, 气流冲击雾化喷嘴出口速度表现出明显的增加趋势, 且仿真结果与理论计算结果误差在10%范围以内。随着窄缝倾角的增加, 负压涡流逐步向进粉管靠近, 回流区、分离区和混合区的最大速度值表现出单调增加的变化规律; 综合考虑气流冲击效果和喷射速度, 确定最优的窄缝倾角50°~60°。Abstract: The structure and working principle of atomizing nozzle by circular seam air impact were analyzed, the numerical simulation model on flow field distribution of atomizing nozzle was studied, and the effects of inlet pressure and circular seam inclination on velocity distribution in flow field were investigated. The results show that, the acceleration of air velocity remains unchanged from the inlet of intake pipe to the exit of air impact atomizing nozzle, and the maximum is achieved at 80 mm away from the center line of intake pipe inlet. With the increasing of inlet pressure, the exit velocity of air impact atomizing nozzle shows an increasing trend obviously, and the error between simulation results and theoretical calculation result is within 10%. With the increasing of circular seam inclination, the negative pressure eddy current is gradually closed to the import of powder tube, the maximum velocity in backflow zone, separation zone, and mixed zone increases monotonously. Considering the air impact effect and jet velocity, the optimal circular seam inclination is determined as 50°~60°.

-

Key words:

- powder atomization /

- nozzle /

- circular seam airflow /

- flow field characteristics /

- numerical simulation

-

表 1 不同进气压力下喷嘴出口速度

Table 1. Exit velocity of atomizing nozzle in different inlet pressure

进气压力/ MPa 喷嘴出口速度/ (m·s-1) 仿真结果 理论计算结果 4 23.4 22.2 6 28.6 26.8 8 34.2 31.5 10 36.8 33.6 表 2 雾化喷嘴不同区域最大速度随窄缝倾角的变化结果

Table 2. Maximum velocity in different zone at different circular seam inclination of atomizing nozzle

窄缝倾角/ (°) 最大速度/ (m·s-1) 涡流区 回流区 分离区 混合区 30 55.4 29.6 25.8 25.0 35 55.2 31.2 27.9 26.9 40 55.2 33.5 31.8 29.8 45 55.7 34.9 33.1 30.1 50 55.1 36.0 34.2 31.2 55 55.3 37.1 35.0 33.3 60 55.6 38.2 35.8 34.2 65 54.8 41.8 36.6 35.8 70 54.5 43.4 36.9 36.1 75 55.1 43.8 37.1 36.6 80 53.8 44.3 37.5 36.9 85 54.6 45.2 37.9 37.1 -

[1] Chen S Q, Huang B Y. The status and development of gas atomization for production of metal powders. Powder Metall Technol, 2004, 22(5): 297 doi: 10.3321/j.issn:1001-3784.2004.05.009陈仕奇, 黄伯云.金属粉末气体雾化制备技术的研究现状与进展.粉末冶金技术, 2004, 22(5): 297 doi: 10.3321/j.issn:1001-3784.2004.05.009 [2] Chen G, Chen Z H, Yan H G, et al. Novel gas atomization method for powder preparation. Chin J Nonferrous Met, 2001, 11(Suppl 2): 33 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ2001S2007.htm陈刚, 陈振华, 严红革, 等.一种新型的气体雾化制粉方法.中国有色金属学报, 2001, 11(增刊2): 33 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ2001S2007.htm [3] Zhao X H, Wang J W, Wang X B, et al. The progress in the preparation and catalytic application of WC nano-powders. Powder Metall Technol, 2012, 30(4): 307 doi: 10.3969/j.issn.1001-3784.2012.04.011赵学华, 王俊文, 王晓斌, 等.纳米WC粉体的制备及其催化应用.粉末冶金技术, 2012, 30(4): 307 doi: 10.3969/j.issn.1001-3784.2012.04.011 [4] Xiong J M, Zou G M, Li P, et al. Experimental study on heat transfer of fan-shaped spray atomizer. Mach Tool Hydraul, 2015, 15: 121 https://www.cnki.com.cn/Article/CJFDTOTAL-JCYY201515032.htm熊建敏, 邹光明, 李萍, 等.扇形雾化喷嘴的射流传热实验研究.机床与液压, 2015, 15: 121 https://www.cnki.com.cn/Article/CJFDTOTAL-JCYY201515032.htm [5] Wang R X, Zhang H R, Liu J H. Study on the technology of preparing ultrafine spherical Ni O by spray drying. Powder Metall Technol, 2013, 31(6): 413 doi: 10.3969/j.issn.1001-3784.2013.06.003王瑞祥, 张焕然, 刘建华.雾化干燥法制备球形超细氧化镍粉工艺研究.粉末冶金技术, 2013, 31(6): 413 doi: 10.3969/j.issn.1001-3784.2013.06.003 [6] Zheng J Q, Luo X Q, Zhang J, et al. Test on the optimum gas consumption rate of pneumatic atomizing nozzle. Trans Chin Soc Agric Mach, 2007, 38(10): 196 https://www.cnki.com.cn/Article/CJFDTOTAL-NYJX200710051.htm郑捷庆, 罗惕乾, 张军, 等.气力式雾化喷嘴最佳气耗率的试验.农业机械学报, 2007, 38(10): 196 https://www.cnki.com.cn/Article/CJFDTOTAL-NYJX200710051.htm [7] Liu F P. Analysis on design parameters of the atomizing nozzle with ring holes. Powder Metall Ind, 2011, 21(1): 40 doi: 10.3969/j.issn.1006-6543.2011.01.007刘福平.环孔雾化喷嘴设计参数的研究.粉末冶金工业, 2011, 21(1): 40 doi: 10.3969/j.issn.1006-6543.2011.01.007 [8] Zeoli N, Gu S. Numerical modelling of droplet break-up for gas atomization. Comput Mater, 2006, 38: 282. doi: 10.1016/j.commatsci.2006.02.012 [9] Cao J H, Rao X X, Lin L J, et al. Research on fluid simulation of atomizer nozzle based on spray powder preparation. Mach Des Manuf, 2013(7): 105 doi: 10.3969/j.issn.1001-3997.2013.07.033曹俊华, 饶锡新, 林立俊, 等.制粉雾化器喷嘴的流场仿真研究.机械设计与制造, 2013(7): 105 doi: 10.3969/j.issn.1001-3997.2013.07.033 [10] Zhang W T, Niu X M, Hu C L, et al. Study on the preparation Ni60A powder by gas atomization with two-stage coupling. Powder Metall Ind, 2012, 22(5): 1 doi: 10.3969/j.issn.1006-6543.2012.05.001张维涛, 牛显明, 胡春莲, 等.双级耦合气雾化制备Ni60A粉末的技术研究.粉末冶金工业, 2012, 22(5): 1 doi: 10.3969/j.issn.1006-6543.2012.05.001 [11] Zhao C Q, Jiang Y. Gas Jet Dynamics. Beijing: Beijing Institute of Technology Press, 1998赵承庆, 姜毅.气体射流动力学.北京: 北京理工大学出版社, 1998 [12] Miller B, Sallam K A, Bingabr M, et al. Secondary breakup of aerated liquid jets in subsonic crossflow(Postprint). J Propul Power, 2008, 24(2): 253. doi: 10.2514/1.30390 [13] Choi J S, Mclaughlin D K, Thompson D E. Experimental on the unsteady flow field and noise generation in a centrifugal pump impeller. J Sound Vib, 2003, 263(3): 493. doi: 10.1016/S0022-460X(02)01061-1 [14] Li H P, He W. A Mathematical model of metallic melts break-up process during gas atomization and spray forming. Material Review, 2008, 23(3): 107 doi: 10.3321/j.issn:1005-023X.2008.03.026李会平, 何伟.气体雾化与喷射成形中雾化过程的数学模型.材料导报, 2008, 22(3): 107 doi: 10.3321/j.issn:1005-023X.2008.03.026 [15] Jia Y M, Zhao Q X, Zhao G H. Fluid Mechanics. Beijing: National Defend Industry Press, 2006贾月梅, 赵秋霞, 赵广慧.流体力学.北京: 国防工业出版社, 2006 -

下载:

下载: