Preparation and electromagnetic properties of high silicon steel soft magnetic composite cores by FCVD-SPS

-

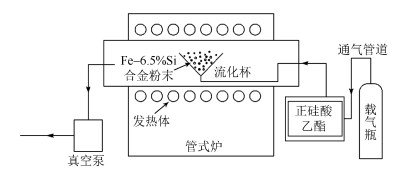

摘要: 采用流化气相原位沉积结合放电等离子烧结工艺成功制备了高硅钢软磁复合铁芯Fe-6.5% Si/SiO2(质量分数),并系统研究了复合铁芯微观结构与电磁性能的关系。结果表明,高硅钢软磁复合铁芯中的Fe-6.5% Si颗粒被SiO2绝缘层均匀并且致密的包围,Fe-6.5% Si/SiO2复合铁芯表现出高磁感、高电阻率、良好的频率稳定性、低矫顽力、以及低铁损等优异的电磁特性,饱和磁感应强度为175 emu·g-1,矫顽力为15 Oe,相对磁导率为350(80 kHz),电阻率为8.6×10-5?·m,0.2 T、5 kHz外场下铁损仅为11.8 W·kg-1。Abstract: The high silicon steel soft magnetic composite cores (Fe-6.5%Si/SiO2 by mass) were successfully prepared by fluidized in-situ chemical vapor deposition combined with the following spark plasma sintering process. The dependence of microstructures on the electrical and magnetic properties of Fe-6.5%Si/SiO2 composite cores was investigated. The results indicate that, most of the conductive Fe-6.5%Si particles are firstly coated with SiO2 in chemical vapor deposition, and then the highly compact and insulated Fe-6.5%Si/SiO2 composite cores are quickly obtained in the next spark plasma sintering. The as-prepared Fe-6.5%Si/SiO2 composite cores display the excellent electromagnetic properties as the saturation magnetization of 175 emu·g-1, the coercivity of 15 Oe, the relative permeability of 350 at 80 kHz, the electrical resistivity of 8.6×10-5?·m, and the core loss of 11.8 W·kg-1 at the magnetic field of 0.2 T and 5 kHz.

-

图 4 无SiO2包覆Fe–6.5%Si软磁铁芯和Fe–6.5%Si/SiO2软磁铁芯的截面扫描电子显微形貌和X射线衍射图谱:(a)无SiO2包覆Fe–6.5%Si软磁铁芯截面显微形貌;(b)Fe–6.5%Si/SiO2软磁铁芯截面显微形貌;(c)X射线衍射图谱

Figure 4. Cross-section SEM images and XRD profiles of Fe–6.5%Si cores and Fe–6.5%Si/SiO2 composite cores: (a) cross-section SEM images of Fe–6.5%Si cores; (b) cross-section SEM images of Fe–6.5%Si/SiO2 composite cores; (c) XRD patterns

表 1 流化气相原位沉积前后Fe–6.5%Si合金粉末表面成分

Table 1. Surface chemical compositions of Fe–6.5%Si alloy powders before and after FCVD

% 元素 流化气相原位沉积前原料粉末表面成分/% 流化气相原位沉积后粉末表面成分/% 质量分数 原子数分数 质量分数 原子数分数 Fe 92.77 86.58 82.68 63.72 Si 7.23 13.42 8.89 13.63 O 0 0 8.43 22.65 总计 100 100 100 100 表 2 无SiO2包覆Fe–6.5%Si软磁铁芯、Fe–6.5%Si/SiO2软磁复合铁芯和JFE生产的传统Fe–6.5%Si软磁铁芯电磁性能比较

Table 2. Electric and magnetic characteristics of Fe–6.5%Si cores, Fe–6.5%Si/SiO2 composite cores, and Fe–6.5%Si alloy cores by JFE

分类 厚度/ mm 电阻率/ (Ω·m) 铁损,Wi/j* / (W·kg; -1) W1/50 W1/400 W1/1 k W0.5/2 k W0.2/5 k 无SiO2包覆Fe–6.5%Si软磁铁芯 10 9.7 × 10;-7 21.7 108.2 358.4 248.2 191.3 Fe–6.5%Si/SiO2软磁复合铁芯(本实验) 10 8.6 × 10;-5 1.6 11.2 36.8 22.4 11.8 传统Fe–6.5%Si软磁铁芯(JFE) — — 1.2 14.5 51.6 29.1 17.9 *Wi/j是指在外场强度i(单位:T)、外场频率j(单位:Hz)条件下测试材料的铁损值。 -

[1] Takashi D, Hironori N. High silicon steel sheet realizing excellent high frequency reactor performance // Applied Power Electronics Conference and Exposition. Austin, 2005: 1740 [2] Fan X A, Wu Z Y, Li G Q, et al. MA–SPS preparation technology and magnetic properties of high silicon electrical steel core. Powder Metall Technol, 2013, 31(4): 267 doi: 10.3969/j.issn.1001-3784.2013.04.006樊希安, 吴朝阳, 李光强, 等. 高Si电工钢铁芯的MA–SPS制备工艺和磁性能研究. 粉末冶金技术, 2013, 31(4): 267 doi: 10.3969/j.issn.1001-3784.2013.04.006 [3] Yang K, Liang Y F, Ye F, et al. Texture evolution of Nb micro-alloyed Fe14Si2 high silicon steel during warm rolling. Acta Metall Sinica, 2013, 49(11): 1411 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201311021.htm杨琨, 梁永锋, 叶丰, 等. Nb微合金化Fe14Si2高硅钢温轧板织构演变规律. 金属学报, 2013, 49(11): 1411 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201311021.htm [4] Fu H D, Zhang Z H, Wu X S, et al. Effects of boron on microstructure and mechanical properties of Fe–6.5%Si alloy fabricated by directional solidification. Intermetallics, 2013, 35: 67 doi: 10.1016/j.intermet.2012.12.005 [5] Wang D, Zhou C, Xu G J, et al. Heat transfer behavior of top side-pouring twin-roll casting. J Mater Process Technol, 2014, 214(6): 1275 doi: 10.1016/j.jmatprotec.2014.01.009 [6] Xie J X, Fu H D, Zhang Z H, et al. Deformation twinning feature and its effects on significant enhancement of tensile ductility in columnar-grained Fe–6.5%Si alloy at intermediate temperatures. Intermetallics, 2012, 23: 20 doi: 10.1016/j.intermet.2011.12.011 [7] Tian G K, Sun Y, Kong L G, et al. Study on the evolution of microstructure and properties in preparing Fe–6.5%Si alloy by means of PVD method. J Funct Mater, 2015, 46(1): 1117 doi: 10.3969/j.issn.1001-9731.2015.01.024田广科, 孙勇, 孔令刚, 等. PVD法渗Si制备6.5%Si高硅钢过程组织结构与性能演化研究. 功能材料, 2015, 46(1): 1117 doi: 10.3969/j.issn.1001-9731.2015.01.024 [8] Long Q, Zhong Y B, Li F, et al. Effect of static magnetic field on the morphology and Si content of Fe–Si composite coating. Acta Metall Sinica, 2013, 49(10): 1201 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201310007.htm龙琼, 钟云波, 李甫, 等. 稳恒磁场对Fe–Si复合电镀层形貌及Si含量的影响. 金属学报, 2013, 49(10): 1201 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201310007.htm [9] Ma L, Xiang L, Qiu S T, et al. Effect of normalizing on magnetic property of 5.28%Si–1.11%Al non-oriented high silicon steel produced by twin roll thin strip casting. Heat Treat Met, 2013, 38(6): 58 doi: 10.3969/j.issn.1673-4971.2013.06.013马良, 项利, 仇圣桃, 等. 正火对双辊薄带连铸5.28%Si–1.11%Al无取向高硅钢磁性能的影响. 金属热处理, 2013, 38(6): 58 doi: 10.3969/j.issn.1673-4971.2013.06.013 [10] Li R, Shen Q, Zhang L M, et al. Magnetic properties of high silicon iron sheet fabricated by direct powder rolling. J Magn Magn Mater, 2004, 281(2-3): 135 doi: 10.1016/j.jmmm.2004.04.098 [11] Yuan W J, Shen Q, Zhang L M. Research on Fe–6.5%Si silicon steel produced by powder rolling technique. Powder Metall Technol, 2007, 25(1): 32 doi: 10.3321/j.issn:1001-3784.2007.01.008员文杰, 沈强, 张联盟. 粉末轧制法制备Fe–6.5%Si硅钢片的研究. 粉末冶金技术, 2007, 25(1): 32 doi: 10.3321/j.issn:1001-3784.2007.01.008 [12] Wu Z Y, Fan X A, Wang J, et al. Core loss reduction in Fe–6.5%Si/SiO2 core-shell composites by ball milling coating and spark plasma sintering. J Alloys Compd, 2014, 617: 21 doi: 10.1016/j.jallcom.2014.07.217 [13] Ma T G, Li H, Tian G K, et al. Study on the evolution of magnetic properties in preparing Fe–6.5%Si alloy by means of PVD method. J Funct Mater, 2016, 47(4): 4196 doi: 10.3969/j.issn.1001-9731.2016.04.040马天国, 李辉, 田广科, 等. PVD法制备6.5%Si高硅钢过程合金磁性能演化机理研究. 功能材料, 2016, 47(4): 4196 doi: 10.3969/j.issn.1001-9731.2016.04.040 [14] Wu Z Y, Jiang Z, Fan X A, et al. Based on the Heterogeneity of Injection Fluidization Device and the Preparation Methods of Preparation of Composite Powder: China Patent, 201034548. 2008–3–12吴朝阳, 江志, 樊希安, 等. 一种基于喷吹流化的异质复合粉末的制备装置及制备方法: 中国专利, 2017108046172. 2017–9–8 [15] Fan X A, Wu Z Y, Li G Q, et al. High resistivity and low core loss of intergranular insulated Fe–6.5wt. %Si/SiO2 composite compacts. Mater Des, 2016, 89: 1251 doi: 10.1016/j.matdes.2015.10.087 [16] Zhang J F, Zhang X, Li G Y, et al. Densification of hBN with the as-coated SiO2 nanolayer by rotary chemical vapor deposition. J Ceram Soc Jpn, 2015, 123(5): 423 http://ci.nii.ac.jp/naid/130005068639 [17] Yanai H, Kawazoe K, Kuwazuru Y, et al. Study for the possibility of utilization of lower volatility material in thin film deposition by the vacuum ultraviolet CVD. Memoirs Faculty Eng Miyazaki Univ, 2015, 44: 77柳井秀仁, 川添圭祐, 桑水流康記, 等. 真空紫外光CVDによる薄膜形成技術における難気化原料使用の可能性の検討. 宮崎大學工學部紀要, 2015, 44: 77 -

下载:

下载: