Preparation and properties of porous layer in copper based high flux heat transfer tube

-

摘要: 烧结型高通量换热管是通过在普通换热管内表面烧结一定厚度的多孔金属层达到强化沸腾传热的效果,多孔层的烧结温度对基管性能不能有损伤,同时要求多孔层本身孔隙连通,与基管结合较好,且耐蚀性与基管相当。本文设计了一种适用于铁白铜基管(BFe10-1-1)的管内多孔层烧结合金粉末Cu-10% Ni-20% Zn-2% Sn(质量分数),该粉末成分耐蚀性优于基管。烧结实验结果表明,该合金粉末在940℃下烧结时对基管性能无损伤,烧结后与基管结合良好,同时粉末多孔层内部孔隙均匀联通;进一步的应用实验也证明,该多孔层合金粉末具有非常好的传热效果。Abstract: The sintered high flux heat transfer tube shows the effect of strengthening boiling heat transfer by sintering the porous metal layer with a certain thickness on the inner surface of ordinary heat transfer tube. It is required that the sintering temperature of porous layer cannot damage the base tube properties, the pores in porous layer should be connected and well bonded to the base tube, and the corrosion resistance of porous layer should be similar with that of base tube. A novel alloy powder was designed as Cu-10%Ni-20%Zn-2%Sn by mass in this paper, which is suitable for sintering the inside porous layer used in copper based high flux heat transfer tube (BFe10-1-1), the corrosion resistance of this alloy powder was higher than that of the base tube. The sintering experiment results show that, sintering this alloy powder at 940℃ has no damage to the base tube properties, and the inside porous layer sintered by this alloy powder shows a good bond with the base tube. Meanwhile, the internal pores in porous layer are uniformly connected. Further application experiments also demonstrate that the alloy powder used for porous layer in this paper has an excellent effect on the heat transfer.

-

Key words:

- high flux /

- heat transfer tube /

- copper based powders /

- porous layer /

- sintering temperature

-

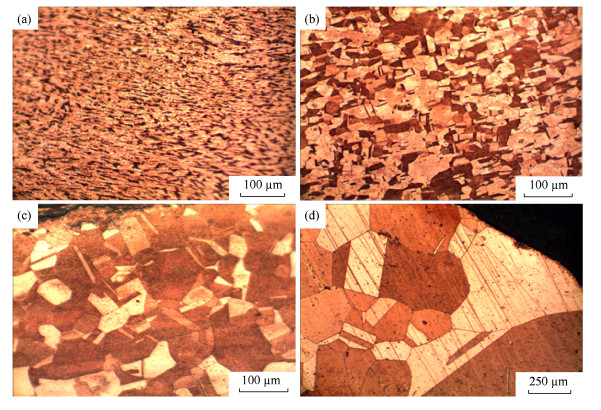

图 3 不同烧结温度下合金管内多孔层显微形貌:(a)900 ℃横截面;(b)900 ℃表面;(c)940 ℃横截面;(d)940 ℃表面

Figure 3. Microstructures of porous layer in alloy tube sintered at different temperatures: (a) cross section morphology at 900 ℃; (b) surface morphology at 900 ℃; (c) cross section morphology at 940 ℃; (d) surface morphology at 940 ℃

表 1 实验用铁白铜管(BFe10-1-1)力学性能标准

Table 1. Mechanical properties of BFe10-1-1 tube for heat exchangers

标准 材质 状态 力学性能 晶粒度/ μm 抗拉强度/ MPa 屈服强度/ MPa 延伸率/ % GB/T 8890–2015 BFe10-1-1

(CuNi10Mn1Fe1)Y2

(半硬态)345 — 10 10~50 表 2 烧结温度对基管晶粒尺寸和力学性能的影响

Table 2. Effect of sintering temperature on grain size and mechanical properties of based tube

烧结温度/ ℃ 平均晶粒尺寸/ μm 抗拉强度/ MPa 延伸率/ % 屈服强度/ MPa 半硬态原始管 晶粒严重变形,无法测量 366 22.0 171 900 20.0 380 22.0 171 940 22.5 381 21.5 173 960 48.0 364 19.3 164 970 55.0 350 17.5 160 995 63.4 340 16.0 155 国外进口成品烧结管 440.0 无法测量 无法测量 无法测量 GB/T 8890–2015 10.0~50.0 345 10.0 — 表 3 致密块状或片状材料的耐蚀性比较

Table 3. Corrosion resistance comparison of different materials as compact block or flake

试样 材质 腐蚀电流/ A 强弱 合金块 Cu–10%Ni–20%Zn–2%Sn 1.271× 10-6 1 原始基管 BFe10-1-1 8.603× 10-6 3 烧后基管 BFe10-1-1 2.618× 10-6 2 进口管

(对比试样)Cu–10%Ni 4.199× 10-5 4 -

[1] Zhao C L, Wang X S, Meng X Y, et al. Experimental study on high-flux tube and design of reboiler. Res Explor Lab, 2016, 35(10): 64 doi: 10.3969/j.issn.1006-7167.2016.10.017赵传亮, 王学生, 孟祥宇, 等. 高通量管实验研究及再沸器设计. 实验室研究与探索, 2016, 35(10): 64 doi: 10.3969/j.issn.1006-7167.2016.10.017 [2] 刘京雷, 徐宏, 徐鹏, 等. 高通量换热器研制开发及应用//全国第四届换热器学术会议. 合肥, 2011: 45Liu J L, Xu H, Xu P, et al. Manufacture and application of high flux heat exchanger // Proceedings of the 4th National Conference on Heat Exchangers. Hefei, 2011: 45 [3] 俞佳, 陆友俊, 张冠文, 等. 高通量换热管与烧结型高通量换热管性能介绍. 中国冶金, 2017, 27(8): 50 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGYE201708012.htm [4] Xu H, Dai Y L, Xia X M, et al. Manufacture of high flux heat exchanger and its application in large scale petrochemical equipment. J Taiyuan Univ Technol, 2010, 41(5): 577 https://www.cnki.com.cn/Article/CJFDTOTAL-TYGY201005030.htm徐宏, 戴玉林, 夏翔鸣, 等. 高通量换热器研制及在大型石化装置中的节能应用. 太原理工大学学报, 2010, 41(5): 577 https://www.cnki.com.cn/Article/CJFDTOTAL-TYGY201005030.htm [5] Lv W. Application of exchanges equipments of high flux tube in the gas separation unit. Pet Chem Equip, 2011, 14(6): 11 doi: 10.3969/j.issn.1674-8980.2011.06.003吕伟. 高通量管换热设备在气分装置上的应用. 石油和化工设备, 2011, 14(6): 11 doi: 10.3969/j.issn.1674-8980.2011.06.003 [6] Tao L Q, Liu J L, Xia X M, et al. Corrosion resistance properties of stainless steel-based porous layer of high flux exchanging tube in acetic acid solution. Chem Ind Eng Prog, 2017, 36(6): 2255 https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201706043.htm陶良权, 刘京雷, 夏翔鸣, 等. 不锈钢基高通量换热管多孔层的耐乙酸腐蚀特性. 化工进展, 2017, 36(6): 2255 https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201706043.htm [7] Huang C L, Zhong J S. Mechanism for enhancing heat transfer of surface porous tube. Equip Manuf Technol, 2007(1): 70 doi: 10.3969/j.issn.1672-545X.2007.01.029黄崇林, 钟经山. 表面多孔管强化传热机理. 装备制造技术, 2007(1): 70 doi: 10.3969/j.issn.1672-545X.2007.01.029 [8] Cieśliński J T. Flow and pool boiling on porous coated surfaces. Rev Chem Eng, 2011, 27(3-4): 179 http://www.degruyter.com/view/j/revce.2011.27.issue-3-4/revce.2011.007/revce.2011.007.xml?format=INT&intcmp=trendmd [9] Liu X F, Li M, Zhao Y T, et al. Domestic design of high flux heat exchanger. Refin Chem Ind, 2011, 22(2): 23 doi: 10.3969/j.issn.1671-4962.2011.02.009刘晓凤, 李梅, 赵院婷, 等. 高通量换热器的国产化设计. 炼油与化工, 2011, 22(2): 23 doi: 10.3969/j.issn.1671-4962.2011.02.009 [10] Liu J S, Cao H H, Yuan Y Z, et al. Brief introduction of sintered surface porous high flux heat exchanger. Process Equip Pip, 2009, 46(Supple 1): 39刘建书, 曹洪海, 袁云中, 等. 烧结型表面多孔高通量换热器简介. 化工设备与管道, 2009, 46(增刊1): 39 [11] Liu K H, Xu H, Huang Z R, et al. A Low-temperature Sintering Method for Porous Surface Tubes: China Patent, CN03116481.1. 2003‒04‒18刘宽宏, 徐宏, 黄志荣, 等. 一种表面多孔管的低温烧结方法: 中国专利, CN03116481.1. 2003‒04‒18 [12] Standardization Administration of the People's Republic of China. GB/T 8890‒2015 Copper Alloy Seamless Tubes for Heat Exchangers. Beijing: China Standards Press, 2016中国国家标准化管理委员会. GB/T 8890‒2015热交换器用铜合金无缝管. 北京: 中国标准出版社, 2016 [13] Dong Q Y. Study of the Effect of Grain Size and Temperature on the Mechanical Properties of Cu‒Zn Alloy [Dissertation]. Chongqing: Chongqing University, 2015董倩玉. 晶粒尺寸与温度对铜锌合金力学性能影响的研究[学位论文]. 重庆: 重庆大学, 2015 [14] Xu Z H. Metal corrosion resistant material, No. 10 copper alloy. Corros Prot, 2001, 22(10): 458 doi: 10.3969/j.issn.1005-748X.2001.10.014徐增华. 金属耐蚀材料, 第十讲铜合金. 腐蚀与防护, 2001, 22(10): 458 doi: 10.3969/j.issn.1005-748X.2001.10.014 [15] Tian R Z, Wang Z T. Copper Alloy and its Processing Manual. Hunan: Central South University Press, 2002田荣璋, 王祝堂. 铜合金及其加工手册. 湖南: 中南大学出版社, 2002 -

下载:

下载: