Effects of carbonfiber content by mass on current-carrying fiction and wear properties of Al2O3 dispersion strengthened copper composites

-

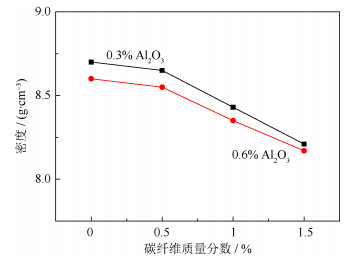

摘要: 通过内氧化法制作出一种Al2O3弥散强化铜-碳纤维复合材料,研究了不同碳纤维质量分数对材料载流摩擦磨损性能的影响。结果表明,碳纤维的加入会影响材料的力学性能,明显降低弥散强化铜材料的摩擦系数和磨损量,提升材料的载流稳定性和载流效率。随着碳纤维质量分数的升高,材料的磨损机制由粘着磨损、熔融堆积变为粘着磨损;随着碳纤维质量分数的进一步增加,材料的磨损形式变为轻微的磨粒磨损,说明碳纤维能够在载流摩擦中起到良好的润滑作用。Abstract: Al2O3 dispersion strengthened copper-carbon fiber composite was prepared by internal oxidation method. The influence of carbon fiber content by mass on the current-carrying friction and wear properties of composites was investigated. The results demonstrate that, the carbon fiber has the effect on the mechanical properties of composites, reduces the friction coefficient and wear rate obviously, and enhances the stability and current-carrying efficiency of composites. With the increase of carbon fiber content by mass, the wear mechanism changes from adhesive wear and fused deposition into adhesive wear. With a further increase of carbon fiber content by mass, the slight abrasive wear becomes the main wear mechanism, which shows that the carbon fiber plays a good lubrication role in current-carrying friction.

-

表 1 摩擦材料组分化学成分(质量分数)

Table 1. Chemical component of friction material

% 试样编号 Al2O3 碳纤维 Cu 1 0.3 0 余量 2 0.3 0.5 余量 3 0.3 1.0 余量 4 0.3 1.5 余量 5 0.6 0 余量 6 0.6 0.5 余量 7 0.6 1.0 余量 8 0.6 1.5 余量 -

[1] Kim S H, Lee D N. The effect of rolling conditions on the strength and microstructure of dispersion strengthened copper strips. Mater Sci Eng A, 2001, 319-321: 471 doi: 10.1016/S0921-5093(01)01040-1 [2] Zhang Y F, Ji Z, Liu G M, et al. Manufacturing process and properties of Al2O3 dispersion strengthened copper-based composite with high electrical conductivity. Powder Metall Technol, 2016, 34(5): 346 doi: 10.3969/j.issn.1001-3784.2016.05.005张一帆, 纪箴, 刘贵民, 等. Al2O3弥散增强Cu基高导电率复合材料的制备及性能研究. 粉末冶金技术, 2016, 34(5): 346 doi: 10.3969/j.issn.1001-3784.2016.05.005 [3] Li C H. Study of graphite action in Al2O3-Cu matrix. Tribology, 2004, 24(6): 572 doi: 10.3321/j.issn:1004-0595.2004.06.020李长虹. 石墨对三氧化二铝/铜金属陶瓷复合材料摩擦磨损性能的影响. 摩擦学学报, 2004, 24(6): 572 doi: 10.3321/j.issn:1004-0595.2004.06.020 [4] Fan T, Liu B W, Sun Y R, et al. Study on wear resistance of Al2O3 particle reinforced Al matrix composites. Powder Metall Technol, 2015, 33(3): 186 doi: 10.3969/j.issn.1001-3784.2015.03.006范涛, 刘博文, 孙艳荣, 等. Al2O3颗粒增强铝基复合材料的耐磨性研究. 粉末冶金技术, 2015, 33(3): 186 doi: 10.3969/j.issn.1001-3784.2015.03.006 [5] Cui H L, Zhao Z M, Zhang L. Progress in functionally graded materials produced by powder metallurgy. Powder Metall Technol, 2013, 31(4): 304 doi: 10.3969/j.issn.1001-3784.2013.04.012崔海龙, 赵忠民, 张龙. 粉末冶金技术制备功能梯度材料研究进展. 粉末冶金技术, 2013, 31(4): 304 doi: 10.3969/j.issn.1001-3784.2013.04.012 [6] Wang J Q, Li G M, Zhao H B. The effect of sintered process on Cu-based powder metallurgy friction materials. Lubr Eng, 2013, 38(10): 76 doi: 10.3969/j.issn.0254-0150.2013.10.018王建强, 李国民, 赵洪波. 烧结工艺对铜基粉末冶金摩擦材料的影响. 润滑与密封, 2013, 38(10): 76 doi: 10.3969/j.issn.0254-0150.2013.10.018 [7] Jiang S W, Zhang Z S, Yan S L, et al. Effect of porosity on the friction and wear performance of wet copper-based friction materials. Mater Sci Eng Powder Metall, 2012, 17(1): 109 doi: 10.3969/j.issn.1673-0224.2012.01.017蒋世文, 张兆森, 严深浪, 等. 孔隙度对湿式铜基摩擦材料摩擦磨损性能的影响. 粉末冶金材料科学与工程, 2012, 17(1): 109 doi: 10.3969/j.issn.1673-0224.2012.01.017 [8] Tang Y P, Liu L, Zhao H J, et al. Study of friction and wear properties of Cu/short carbon fibers composites. J Mater Eng, 2007(4): 53 doi: 10.3969/j.issn.1001-4381.2007.04.014唐谊平, 刘磊, 赵海军, 等. 短碳纤维增强铜基复合材料的摩擦磨损性能研究. 材料工程, 2007(4): 53 doi: 10.3969/j.issn.1001-4381.2007.04.014 [9] Feng Y, Wang W F, Huang S G, et al. Influence of current intensity on electrical wear behaviors of carbon fiber–copper–graphite composite. Lubr Eng, 2000(3): 15 doi: 10.3969/j.issn.0254-0150.2000.03.006凤仪, 王文芳, 黄守国, 等. 电流强度对碳纤维–铜–石墨复合电刷材料电磨损性能的影响. 润滑与密封, 2000(3): 15 doi: 10.3969/j.issn.0254-0150.2000.03.006 [10] Kato H, Takama M, Iwai Y, et al. Wear and mechanical properties of sintered copper–tin composites containing graphite or molybdenum disulfide. Wear, 2003, 255(1-6): 573 doi: 10.1016/S0043-1648(03)00072-3 [11] Stolarski T A, Xue Y. Performance study of a back-depression mechanical dry gas seal. Proc Inst Mech Eng Part J, 1998, 212(4): 279 doi: 10.1243/1350650981542092 [12] Zhou F, Chen K M, Wang M L, et al. Friction and wear properties of CrN coating sliding against Si3N4 balls in water and air. Wear, 2008, 265(7-8): 1029 doi: 10.1016/j.wear.2008.02.010 [13] Zhang G X. Effects of copper-coated graphite content and particle size on properties of the Cu/copper-coated graphite composite. Powder Metall Technol, 2016, 34(3): 196 doi: 10.3969/j.issn.1001-3784.2016.03.007张国玺. 石墨质量分数及粒度对铜–镀铜石墨复合材料性能的影响. 粉末冶金技术, 2016, 34(3): 196 doi: 10.3969/j.issn.1001-3784.2016.03.007 [14] Li S. Study on Sliding Electrical Friction and Wear Properties of Ag Based Composite Electrical Contact Material[Dissertation]. Hefei: Hefei University of Technology, 2009李庶. 银基复合电接触材料滑动电摩擦磨损性能研究[学位论文]. 合肥: 合肥工业大学, 2009 [15] Zhong T S, Li X H, Fu Q Y, et al. Influence of test parameters on performances of carbon fiber–copper composite. Heat Treat, 2015, 30(2): 20 doi: 10.3969/j.issn.1008-1690.2015.02.006钟涛生, 李小红, 付求涯, 等. 试验参数对碳纤维铜复合材料性能的影响. 热处理, 2015, 30(2): 20 doi: 10.3969/j.issn.1008-1690.2015.02.006 [16] Li B Q, Zhang F Q, Yang Z, et al. Frictional wear properties of carbon-fiber-reinforced copper-based self-lubricating composites. Min Metall Eng, 2016, 36(5): 107 doi: 10.3969/j.issn.0253-6099.2016.05.028黎炳前, 张福勤, 杨昭, 等. 碳纤维增强铜基自润滑复合材料的摩擦磨损性能研究. 矿冶工程, 2016, 36(5): 107 doi: 10.3969/j.issn.0253-6099.2016.05.028 [17] Yu Y L, Yuan N, Jiang D L, et al. Effects of nickel and graphite content on new copper matrix P/M materials for pantograph slider. Mater Sci Eng Powder Metall, 2015, 20(3): 419 doi: 10.3969/j.issn.1673-0224.2015.03.014余亚岚, 袁楠, 江丹露, 等. 镍与石墨质量分数对新型铜基粉末冶金受电弓滑板材料性能的影响. 粉末冶金材料科学与工程, 2015, 20(3): 419 doi: 10.3969/j.issn.1673-0224.2015.03.014 -

下载:

下载: