Effect of Cu alloy element on the performance of powder metallurgy surface rolling densification

-

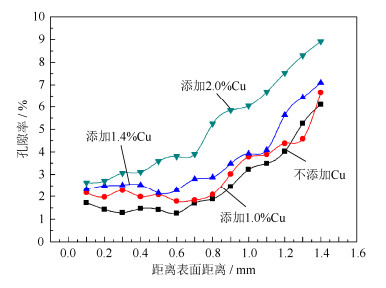

摘要: 表面滚压致密化工艺不仅能降低齿轮齿面的噪音,还能提高齿轮齿面的抗滚动接触疲劳性能,在粉末冶金齿轮生产领域得到广泛应用。滚压粉末冶金坯料的原始成分对滚压致密化效果有很大的影响,本文研究了合金元素Cu的质量分数对滚压效果的影响,从材料的孔隙情况、组织结构、硬度、耐磨性等方面分析讨论了表面滚压致密化工艺原料的选择问题。结果表明,坯料原始成分中Cu质量分数对齿轮用粉末冶金零件的表面致密化行为和性能起到重要作用,Cu质量分数越低,材料的合金化程度越低,塑性变形抗力越低,在相同的滚压条件下,可以获得较好的表面致密化效果;Cu质量分数的增加有利于提高零件的硬度和耐磨性,当Cu质量分数为1.4%时,零件表面致密层深度为1.13 mm,耐磨性较高,具有最优的综合性能,更适合实际工况的应用。Abstract: Rolling densification process is widely used in manufacture field of powder metallurgy gears, which could reduce the noise and enhance the rolling contact fatigue performance of gears. The original composition of powder metallurgy blank parts has a significant effect on the performance of surface rolling densification. The effect of Cu content by mass on rolling densification was studied in this paper, the influences of raw materials on porosity, structure, hardness, and wearing resistance of powder metallurgy gears in the surface rolling densification process were analyzed and discussed. The results show that, Cu plays an important role on the densification behavior and the properties of powder metallurgy gear parts. Under the same rolling parameters, the parts with lower Cu content have better surface densification performance because of the lower degree of alloying. However, the increase of Cu content is conducive to improve the hardness and wearing resistance of the parts. The parts with 1.4% Cu by mass have the surface dense layer in 1.13 mm and show the high wearing resistance, which have the best overall performance and are more suitable for the actual working conditions applications.

-

Key words:

- surface rolling densification /

- powder metallurgy /

- alloy element /

- copper /

- plastic deformation

-

表 1 实验原料化学成分(质量分数)

Table 1. Chemical composition of raw material

% 试样编号 Astaloy85Mo C Cu 1 余量 0.8 — 2 余量 0.8 1.0 3 余量 0.8 1.4 4 余量 0.8 2.0 -

[1] Menapace C, Molinari A, Kazior J, et al. Surface self-densification in boron alloyed austenitic stainless steel and its effect on corrosion and impact resistance. Powder Metall, 2007, 50(4): 326 doi: 10.1179/174329007X205028 [2] Takemasu T, Koide T, Takeda Y, et al. Properties of densification by surface rolling and load bearing capacity of 1.5Cr–0.2Mo high density sintered steel rollers and gears. J Solid Mech Mater Eng, 2011, 5(12): 825 doi: 10.1299/jmmp.5.825 [3] Fordén L, Bengtsson S, Bergström M. Comparison of high performance PM gears manufactured by conventional and warm compaction and surface densification. Powder Metall, 2005, 48(1): 10 doi: 10.1179/pom.2005.48.1.10 [4] Lawcoek R. Rolling-contact fatigue of surface-densified gears. Int J Powder Metall, 2006, 42(1): 17 http://ci.nii.ac.jp/naid/80019214290 [5] Takemasu T, Koide T, Shinbutsu T, et al. Effect of surface rolling on load bearing capacity of pre-alloyed sintered steel gears with different densities. Procedia Eng, 2014, 81: 334 doi: 10.1016/j.proeng.2014.10.002 [6] Yu Y, Fordén L. Surface densification—an effective way to improve the performance of sintered gears. Powder Metall Technol, 2005, 23(1): 62 doi: 10.3321/j.issn:1001-3784.2005.01.013于洋, Fordén L. 表面致密化—一种提高烧结齿轮性能的有效方法. 粉末冶金技术, 2005, 23(1): 62 doi: 10.3321/j.issn:1001-3784.2005.01.013 [7] Slattery R, Hanejko F, Rawlings A, et al. Powder metallurgy of high density helical gears. Powder Metall Ind, 2012, 22(4): 1 doi: 10.3969/j.issn.1006-6543.2012.04.001Slattery R, Hanejko F, Rawlings A, 等. 高密度粉末冶金螺旋齿轮. 粉末冶金工业, 2012, 22(4): 1 doi: 10.3969/j.issn.1006-6543.2012.04.001 [8] Fordén L, Bengtsson S, Bergström M. PM takes on truck test in the gearbox. Met Powder Rep, 2004, 59(11): 14 doi: 10.1016/S0026-0657(04)00298-X [9] Bengtsson S, Fordén L, Johansson P, et al. Rolling contact fatigue tests of selectively densified materials // Automotive and Transportation Technology Congress and Exposition. Barcelona, 2001: 370 [10] Trasorras J R L, Nigarura S, Sigl L S. DensiForm® technology for wrought-steel-like performance of powder metal components // 2006 SAE World Congress. Michigan, 2006: 398 [11] Peng J J, Chen D, Li D K, et al. Process development of surface rolling densification powder metallurgy sprockets. Powder Metall Technol, 2016, 34(6): 450 doi: 10.3969/j.issn.1001-3784.2016.06.010彭景光, 陈迪, 李德凯, 等. 粉末冶金表面滚压致密化链轮工艺的开发. 粉末冶金技术, 2016, 34(6): 450 doi: 10.3969/j.issn.1001-3784.2016.06.010 [12] Liu X, Xiao Z Y, Guan H J, et al. Experimental study on the surface densification of Fe–2Cu–0.6C powder metallurgy material. Mater Manuf Processes, 2016, 31(12): 1621 doi: 10.1080/10426914.2015.1117619 -

下载:

下载: