-

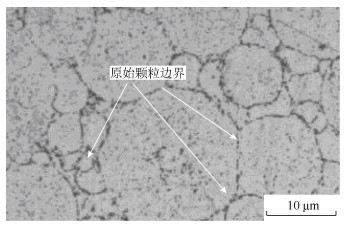

摘要: 通过Gleeble-1500热模拟试验机对热等静压成形FGH96高温合金进行热压缩试验,其中温度为1075℃,变形速率为0.001 s-1,变形量为70%。利用场发射扫描电镜、透射电镜和电子能谱研究了合金原始颗粒边界(prior particle boundary,PPB)的组成,讨论了原始颗粒边界在FGH96高温合金再结晶过程中的作用,并分析了合金热变形对原始颗粒边界的影响。结果表明:热等静压成形FGH96高温合金中的原始颗粒边界主要由Ti的碳化物和γˊ相共同组成;原始颗粒边界对合金热变形再结晶形核起促进作用,对晶粒长大起阻碍作用;合金热变形可以改善原始颗粒边界在组织中的分布,从而使晶粒长大过程顺利进行。Abstract: The hot compression test of FGH96 superalloy made by hot isostatic pressing was carried out on Gleeble-1500 thermal simulator at 1075℃ with the deformation of 70% under the deformation rate of 0.001 s-1. Field emission scanning electron microscopy, transmission electron microscopy, and electron spectroscopy were used to study the composition of prior particle boundary (PPB), the role of PPB on the recrystallization FGH96 superalloy was investigated, and the effect of alloy thermal deformation on PPB was analyzed. The results show that, the prior particle boundary in hot isostatic pressed FGH96 superalloy mainly consists of Ti carbide and γ' phase. The PPBs play the promoting role on recrystallization nucleation and hinder the grain growth. The thermal deformation can improve the distribution of PPB, which is in favour of the grain growth process.

-

Key words:

- superalloy /

- hot compression /

- prior particle boundary /

- recrystallization

-

表 1 FGH96高温合金的化学成分(质量分数)

Table 1. Chemical composition of FGH96 superalloy

% Ni Cr Co Mo Al Ti W Nb C B Zr 55.68 15.78 13.04 4.33 4.14 3.88 2.26 0.82 0.03 0.01 0.03 表 2 热等静压FGH96合金中原始颗粒边界的能谱分析(质量分数)

Table 2. Energy spectrum analysis of PPB in HIPed FGH96 superalloy

% 颗粒形貌 Ni Ti Nb W Cr Mo Al Co Zr C 细小颗粒 5.30 45.64 4.12 0.84 0.36 0.16 ― ― 0.44 粗大片状颗粒 59.89 7.40 3.88 3.62 2.86 1.40 7.83 12.65 0.47 ― -

[1] Hu B F, Chen H M, Jin K S, et al. Static recrystallization mechanism of FGH95 superalloy. Chin J Nonferrous Met, 2004, 14(6): 901 doi: 10.3321/j.issn:1004-0609.2004.06.004胡本芙, 陈焕铭, 金开生, 等. FGH95高温合金的静态再结晶机制. 中国有色金属学报, 2004, 14(6): 901 doi: 10.3321/j.issn:1004-0609.2004.06.004 [2] Zhang Y W, Shangguan Y H. Research and development in P/M superalloy. Powder Metall Ind, 2004, 14(6): 30 doi: 10.3969/j.issn.1006-6543.2004.06.006张义文, 上官永恒. 粉末高温合金的研究与发展. 粉末冶金工业, 2004, 14(6): 30 doi: 10.3969/j.issn.1006-6543.2004.06.006 [3] Jia J, Tao Y, Zhang Y W, et al. Resent development of third generation P/M superalloy René104. Powder Metall Ind, 2007, 17(3): 36 doi: 10.3969/j.issn.1006-6543.2007.03.008贾建, 陶宇, 张义文, 等. 第三代粉末冶金高温合金René104的研究进展. 粉末冶金工业, 2007, 17(3): 36 doi: 10.3969/j.issn.1006-6543.2007.03.008 [4] Luo X Y. Research on Fatigue-Danmage-Fracture and Micro-mechanism of GH4133B Superalloy Used in Turbine Disk of Aero-Engine [Dissertation]. Xiangtan: Xiangtan University, 2011罗希延. 航空发动机涡轮盘用GH4133B合金疲劳损伤断裂与微观机理研究[学位论文]. 湘潭: 湘潭大学, 2011 [5] Payton E J, Wynn T A, Mills M J. Experimental measurement of the kinetics of gamma prime dissolution during supersolvus heat treatment of powder metallurgical Ni-based disk superalloys. J Mater Sci, 2012, 47(20): 7305 doi: 10.1007/s10853-012-6684-8 [6] Zerbst U, Madia M, Hellmann D. An analytical fracture mechanics model for estimation of S–N curves of metallic alloys containing large second phase particles. Eng Fract Mech, 2012, 82: 115 doi: 10.1016/j.engfracmech.2011.12.001 [7] Bozzolo N, Souaï N, Logé R E. Evolution of microstructure and twin density during thermomechanical processing in a γ-γ' nickel-based superalloy. Acta Mater, 2012, 60(13-14): 5056 doi: 10.1016/j.actamat.2012.06.028 [8] Zhao J P. Study on Prior Particle Boundary (PPB) Precipitation in P/M Superalloy FGH96[Dissertation]. Xi'an: Xi'an University of Architecture and Technology, 2010赵军普. FGH96粉末高温合金原始颗粒边界(PPB)问题的研究[学位论文]. 西安: 西安建筑科技大学, 2010 [9] Souaï N, Bozzolo N, Nazé L, et al. About the possibility of grain boundary engineering via hot-working in a nickel-base superalloy. Scripta Mater, 2010, 62(11): 851 doi: 10.1016/j.scriptamat.2010.02.019 [10] Radavich J, Furrer D. Assessment of Russian P/M superalloy EP741NP. Miner Met Mater Soc, 2004: 381 http://www.researchgate.net/publication/267686632_Assessment_of_Russian_PM_superalloy_EP741NP [11] Peng H L. Microstructure and Properties Analysis of Nickel-based Superalloy Powders Prepared by Gas Atomization [Dissertation]. Guangzhou: South China University of Technology, 2016彭翰林. 镍基高温合金粉末组织结构分析及性能研究[学位论文]. 广州: 华南理工大学, 2016 [12] Ma W B, Liu G Q, Hu B F, et al. Formation of previous particle boundary of nickel base PM superalloy FGH96. Acta Metall Sinica, 2013, 49(10): 1248 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201310013.htm马文斌, 刘国权, 胡本芙, 等. 镍基粉末高温合金FGH96中原始粉末颗粒边界的形成机理. 金属学报, 2013, 49(10): 1248 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201310013.htm [13] Hu W B, Jia C C, Hu B F, et al. The previous particle boundaries (PPB) of FGH96 superalloy and its effects on impact property. Powder Metall Technol, 2012, 30(5): 327 doi: 10.3969/j.issn.1001-3784.2012.05.002胡文波, 贾成厂, 胡本芙, 等. FGH96合金原始颗粒边界(PPB)及其对冲击性能的影响. 粉末冶金技术, 2012, 30(5): 327 doi: 10.3969/j.issn.1001-3784.2012.05.002 [14] Zhao J Q, Liu J, Zhang Y D, et al. Effect of aging temperature on PPB and mechanical properties of PM FGH96 alloy. Powder Metall Ind, 2015, 25(5): 47 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201505015.htm赵剑青, 刘晶, 张银东, 等. 时效温度对粉末FGH96合金的PPB和力学性能的影响. 粉末冶金工业, 2015, 25(5): 47 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201505015.htm [15] Liu J T, Zhang Y W, Tao Y, et al. Investigation on dynamic recrystallization of FGH96 powder metallurgy superalloy. Trans Mater Heat Treat, 2006, 27(5): 46 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL200605012.htm刘建涛, 张义文, 陶宇, 等. FGH96合金动态再结晶行为的研究. 材料热处理学报, 2006, 27(5): 46 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL200605012.htm [16] Han S B, Zhang Y W, Liu M D. Effects of hafnium content on prior particle boundary precipitation in P/M superalloy FGH4097. J Iron Steel Res, 2011, 23(Suppl 2): 502 https://www.cnki.com.cn/Article/CJFDTOTAL-IRON2011S2131.htm韩寿波, 张义文, 刘明东. Hf含量对FGH4097粉末冶金高温合金PPB的影响. 钢铁研究学报, 2011, 23 (增刊2): 502 https://www.cnki.com.cn/Article/CJFDTOTAL-IRON2011S2131.htm -

下载:

下载: