-

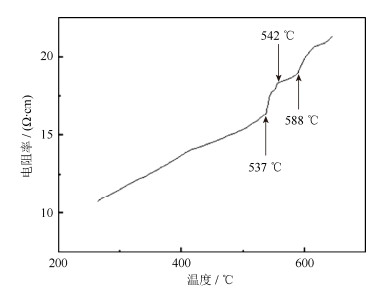

摘要: 通过粉末冶金技术制备质量分数为7.5%的含铜铝基烧结含油轴承试样,研究了在氮气保护下不同烧结温度以及烧结时间对试样的微观结构和综合性能的影响,优化得到最佳烧结工艺。研究结果表明,当烧结温度超过537℃时,烧结试样发生局部熔化,液相开始生成;随着烧结温度升高和烧结时间的延长,烧结试样的尺寸收缩率以及压溃强度不断提高而含油率不断减小。当烧结温度为560℃、烧结时间为120 min时,烧结试样拥有良好的综合性能,压溃强度和含油率分别为151.3 MPa和16.7%,呈最佳烧结状态。Abstract: The Al-based sintered oil bearing (containing 7.5% Cu by mass) was prepared by powder metallurgy in N2 atmosphere, the effects of sintering temperature and sintering time on the microstructures and comprehensive performances of Al-based sintered oil bearing were investigated, and the optimal sintering processing was obtained in this paper. The results show that, when the sintering temperature is beyond 537℃, the powder particles are partly molten, and the liquid phase is generated. With the increase of sintering temperature and the extension to sintering time, the dimensional shrink rate and crushing strength are increased, but the oil content is decreased. The optimal comprehensive performances of Al-based sintered oil bearing are obtained when the bearing samples are sintered at 560℃ for 120 min, and the crushing strength and oil content reaches 151.3 MPa and 16.7%, respectively.

-

Key words:

- powder metallurgy /

- Al-based sintered oil bearing /

- sintering process /

- crushing strength /

- oil content

-

表 1 不同烧结温度下试样的压溃强度及含油率

Table 1. Crushing strength and oil content of sintered samples at different sintering temperatures

烧结温度/ ℃ 压溃强度/ MPa 含油率/ % 530 45.1 20.2 540 95.7 19.8 550 131.7 17.5 560 151.3 16.7 570 162.2 14.3 580 197.4 12.0 590 207.3 8.2 表 2 不同烧结温度下试样的尺寸收缩率

Table 2. Dimensional change of samples sintered at different sintering temperatures

烧结温度/ ℃ 轴向变化率/ % 径向变化率/ % 530 -0.42 -0.21 540 -0.89 -0.41 550 -1.21 -0.97 560 -2.61 -1.17 570 -3.42 -1.44 580 -4.90 -2.70 590 -5.70 -3.10 -

[1] Jia C C. Sintering metal oil bearing. Met World, 2011(1): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-JSSJ201101011.htm贾成厂. 烧结金属含油轴承. 金属世界, 2011(1): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-JSSJ201101011.htm [2] Dong X J, Wang L M, Zhang J H, et al. Influence of morphology of different partially alloyed CuSn10 powders on the sintering character of self lubricated bearings. Powder Metall Ind, 2010, 20(4): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201004015.htm董小江, 汪礼敏, 张景怀, 等. 不同形貌部分合金化CuSn10粉末对含油轴承烧结性能的影响. 粉末冶金工业, 2010, 20(4): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201004015.htm [3] Wang B, Zha W S, An X G. Effects of ball milling time on crushing strength and oil content of Al–Cu oil-impregnated bearing. Powder Metall Technol, 2014, 32(2): 92 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201402003.htm王博, 査五生, 安旭光. 球磨时间对铝铜含油轴承压溃强度和含油率的影响. 粉末冶金技术, 2014, 32(2): 92 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ201402003.htm [4] Wang Z T, Tian R Z. Aluminum Alloy and Its Processing Manual. 3rd Ed. Changsha: Central South University Press, 2005王祝堂, 田荣璋. 铝合金及其加工手册. 3版. 长沙: 中南大学出版社, 2005 [5] Wang J Q, Li G M, Zhao H B. The effect of sintered process on Cu-based powder metallurgy friction materials. Lubr Eng, 2013, 38(10): 76 doi: 10.3969/j.issn.0254-0150.2013.10.018王建强, 李国民, 赵洪波. 烧结工艺对铜基粉末冶金摩擦材料的影响. 润滑与密封, 2013, 38(10): 76 doi: 10.3969/j.issn.0254-0150.2013.10.018 [6] Liu J Y, Zou C P, Zha W S, et al. Effect of sintering temperature on microstructure and compressive strength of B4C–AlSi eutectic alloy. Nucl Power Eng, 2008, 29(2): 58 https://www.cnki.com.cn/Article/CJFDTOTAL-HDLG200802013.htm刘锦云, 邹从沛, 査五生, 等. 烧结温度B4C–AlSi共晶合金显微组织结构与抗压强度的影. 核动力工程, 2008, 29(2): 58 https://www.cnki.com.cn/Article/CJFDTOTAL-HDLG200802013.htm [7] Huang P Y. Theory of Power Metallurgy. Beijing: Metallurgical Industry Press, 2008黄培云. 粉末冶金原理. 北京: 冶金工业出版社, 2008 [8] Qian H J. Effect of Sintering Process and Alloy Element on Microstructure and Mechanical Properties of Cu-based Oil-impregnated Bearing [Dissertation]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2016钱杭君. 烧结工艺及合金元素对铜基含油轴承组织与性能的影响[学位论文]. 南京: 南京航空航天大学, 2016 [9] Hu S L, Zha W S, Jia Y C. Effect of the copper content on Al–Cu sintered materials. Sichuan Nonferrous Met, 2010(4): 24 https://www.cnki.com.cn/Article/CJFDTOTAL-ACJS201004007.htm胡绍磊, 查五生, 贾永灿. 铜含量对铝铜烧结材料性能影响. 四川有色金属, 2010(4): 24 https://www.cnki.com.cn/Article/CJFDTOTAL-ACJS201004007.htm [10] Xu J J, Deng Z Y, Zhang T J. Analyses of Physical Properties of Metals. Shanghai: Shanghai Scientific & Technical Publishers, 1988徐京娟, 邓志煜, 张同俊. 金属物理性能分析. 上海: 上海科学技术出版社, 1988 [11] Lin Y, Chai D L, Zhang W X. Study on sintering process of alloys of Al–Zn and Al–Cu binary systems. Powder Metall Ind, 2007, 17(4): 10 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG200704005.htm林芸, 柴东朗, 张文兴. Al–Zn、Al–Cu二元合金系烧结过程的对比研究. 粉末冶金工业, 2007, 17(4): 10 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG200704005.htm [12] Yu J, Zhang Y, Zu F Q, et al. Change character of electrical resistivity with temperature of Sn–Zn alloys. Chin J Nonferrous Met, 2006, 16(8): 1337 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ200608004.htm余瑾, 张燕, 祖方遒, 等. 二元SnZn合金的电阻随温度变化的特性. 中国有色金属学报, 2006, 16(8): 1337 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ200608004.htm [13] An X G, Zha W S, Lei Y, et al. Effect of sintering temperature on crushing strength, oil content and microstructure of Al–Cu oil bearing. Powder Metall Technol, 2012, 30(2): 108 doi: 10.3969/j.issn.1001-3784.2012.02.005安旭光, 查五生, 雷宇, 等. 烧结温度对Al–Cu系含油轴承压溃强度、含油率和微观形貌的影响. 粉末冶金技术, 2012, 30(2): 108 doi: 10.3969/j.issn.1001-3784.2012.02.005 [14] Huang J S, Zhao X Y, Shida M. Effect of sintering technology on mechanical properties of Cu–20Zn brass. Mater Sci Eng Powder Metall, 2010, 15(5): 491 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201005015.htm黄钧声, 赵欣悦, 志田光明. 烧结工艺对Cu–20Zn黄铜力学性能的影响. 粉末冶金材料科学与工程, 2010, 15(5): 491 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201005015.htm [15] Wu S S, Li Y, Mao Y W, et al. Effects of sintering method on density and microstructure of particulate reinforced copper matrix composites. Spec Cast Nonferrous Alloys, 2005, 25(10): 579 https://www.cnki.com.cn/Article/CJFDTOTAL-TZZZ200510002.htm吴树森, 李勇, 毛有武, 等. 烧结工艺对铜基复合材料密度及组织的影响. 特种铸造及有色合金, 2005, 25(10): 579 https://www.cnki.com.cn/Article/CJFDTOTAL-TZZZ200510002.htm -

下载:

下载: