Effects of FeCrBSi pre-alloyed powder on sintering properties of 316L stainless steel by metal injection molding

-

摘要: 研究了添加不同质量分数FeCrBSi铁基预合金粉末(FeCrBSi)作为烧结助剂对金属注射成形316L不锈钢(316L)烧结性能的影响,通过电子密度计、金相显微镜及洛氏硬度计等仪器分析讨论了烧结制品的烧结密度、金相显微组织及硬度等性能。结果表明:在1360℃烧结时,FeCrBSi与316L形成了超固相线液相烧结,液相的增加有利于烧结致密化,烧结密度随着FeCrBSi质量分数的增加而升高,孔隙度逐渐降低。当FeCrBSi质量分数为3%~5%时,烧结密度达到7.81~7.87 g·cm-3;当FeCrBSi质量分数增至7%时,烧结出现变形。制品硬度随相对密度的上升而提高,在FeCrBSi质量分数为3%时达到最大值(HRB 75),此时力学性能亦表现优异。Abstract: Effect of FeCrBSi Fe-based pre-alloyed powder (FeCrBSi) content by mass as sintering additive on sintering properties of 316L stainless steel (316L) by metal injection molding (MIM) was studied. The sintered density, metallurgical microstructures, and hardness of the sintered products were investigated by electronic densitometer, metallurgical microscope, and Rockwell hardometer, respectively. The results indicate that, the supersolidus liquid phase sintering is formed by FeCrBSi and 316L sintered at 1360℃, and the increase in liquid phase is beneficial to the sintering densification. The sintered density is increased with the rise of FeCrBSi mass fraction, and the porosity decreases in contrast. The sintered density is up to 7.81~7.87 g·cm-3 when the FeCrBSi mass fraction is 3%~5%; whereas, the deformation is emerged when the FeCrBSi mass fraction increases to 7%. Hardness is improved with the increased relative density. The maximum hardness is reached as HRB 75, when the mass fraction of FeCrBSi is 3%, and the mechanical properties are also excellent at this time.

-

Key words:

- metal injection molding /

- sintering additive /

- FeCrBSi /

- liquid phase sintering

-

图 4 不锈钢与预合金粉末的超固相线液相烧结[12]

Figure 4. Supersolids liquid phase sintering of stainless steel and pre-alloyed powders

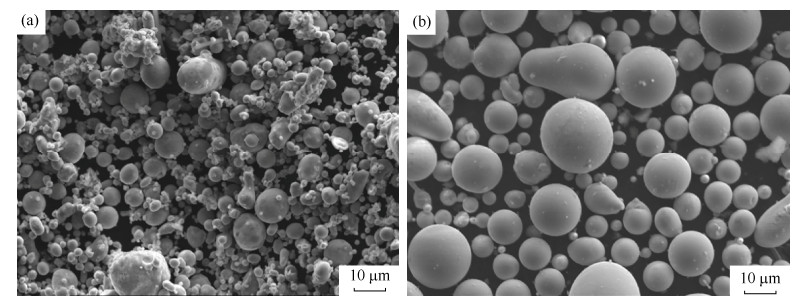

表 1 316L与FeCrBSi粉末物理性能

Table 1. Physical properties of 316L and FeCrBSi powders

粉末 粒径分布/ μm 平均粒径/ μm 振实密度/ (g·cm-3) 氧质量分数/ ×10-6 D10 D50 D90 316L粉末 2.712 9.277 24.51 11.85 4.76 3038 FeCrBSi预合金粉末 7.450 16.74 27.45 17.10 5.10 835 表 2 添加质量分数5%FeCrBSi的316L烧结试样晶界处成分

Table 2. Chemical composition at grain boundary of sintered 316L specimens added with 5% FeCrBSi by mass

位置 Si Cr Mn Fe Ni Mo 位置1 0.00 29.39 11.27 9.74 1.44 48.16 位置2 0.09 23.96 — 38.77 5.22 31.96 位置3 0.41 15.75 — 68.91 13.18 1.76 位置4 — 38.87 — 33.62 3.20 24.31 表 3 添加不同质量分数FeCrBSi的316L烧结件力学性能及耐腐蚀性

Table 3. Mechanical properties and corrosion resistance of sintered 316L parts added by FeCrBSi in different mass fractions

FeCrBSi质量分数/ % 屈服强度,Rp0.2 / (N·mm-2) 抗拉强度,Rm / (N·mm-2) 断后伸长率,A / % 耐腐蚀性时间/ h MPIF 140 455 40 48 0 151 397 43 196 1 199 515 52 202 3 204 559 64.5 216 5 193 505 55 228 7 — — — 72 -

[1] Liu C, Kong X J, Wu S W, et al. Research progress on metal injection molding of titanium and titanium alloys. Powder Metall Technol, 2017, 35(2): 150 doi: 10.3969/j.issn.1001-3784.2017.02.012刘超, 孔祥吉, 吴胜文, 等. 钛及钛合金金属粉末注射成形技术的研究进展. 粉末冶金技术, 2017, 35(2): 150 doi: 10.3969/j.issn.1001-3784.2017.02.012 [2] Xu Y L, Guo Z M, Luo J, et al. The effect of sintering process on the microstructure and properties of 316L stainless steel. Powder Metall Technol, 2014, 32(5): 378 http://pmt.ustb.edu.cn/article/id/fmyjjs201405011徐延龙, 郭志猛, 罗骥, 等. 烧结工艺对316L不锈钢组织与性能的影响. 粉末冶金技术, 2014, 32(5): 378 http://pmt.ustb.edu.cn/article/id/fmyjjs201405011 [3] Zhao L M, Qu X H, He X B, et al. Powder injection moulding of Ti–47.5Al–205V–1.0Cr. J Univ Sci Technol Beijing, 2008, 30(10): 1144 doi: 10.3321/j.issn:1001-053X.2008.10.012赵丽明, 曲选辉, 何新波, 等. Ti–47.5Al–205V–1.0Cr注射成形. 北京科技大学学报, 2008, 30(10): 1144 doi: 10.3321/j.issn:1001-053X.2008.10.012 [4] Gao J X, Fan J L. Rheological behavior study of injection molding feeding for YT5 hardmetal. Cemented Carbide, 2010, 27(6): 338 doi: 10.3969/j.issn.1003-7292.2010.06.004高建祥, 范景莲. YT5硬质合金注射成形喂料流变学行为研究. 硬质合金, 2010, 27(6): 338 doi: 10.3969/j.issn.1003-7292.2010.06.004 [5] Duan B H, Qu X H, Zhang L, et al. Effect of particle size on properties of injection-molded bonded NdFeB magnet. Chin J Nonferrous Met, 2007, 17(10): 1627 doi: 10.3321/j.issn:1004-0609.2007.10.012段柏华, 曲选辉, 章林, 等. 磁粉粒度对注射成形粘结NdFeB磁体性能的影响. 中国有色金属学报, 2007, 17(10): 1627 doi: 10.3321/j.issn:1004-0609.2007.10.012 [6] Wang Y L, Hao J J, Guo Z M, et al. Gelcasting of 316l stainless steel powder. Powder Metall Ind, 2007, 17(3): 19 doi: 10.3969/j.issn.1006-6543.2007.03.004王亚利, 郝俊杰, 郭志猛, 等. 316L不锈钢粉末的凝胶注模成形. 粉末冶金工业, 2007, 17(3): 19 doi: 10.3969/j.issn.1006-6543.2007.03.004 [7] Jiang F, Li Y M, Li S L. Influence of atmosphere to densification and dimensional precision of MIM316L stainless steel. Mater Sci Technol, 2005, 13(1): 4 doi: 10.3969/j.issn.1005-0299.2005.01.002姜峰, 李益民, 李松林. 烧结气氛对MIM316L不锈钢致密化和尺寸精度的影响. 材料科学与工艺, 2005, 13(1): 4 doi: 10.3969/j.issn.1005-0299.2005.01.002 [8] Ozkan Gülsoy H. Dry sliding wear in injection molded 17-4PH stainless steel powder with nickel boride additions. Wear, 2007, 262(3-4): 491 doi: 10.1016/j.wear.2006.05.003 [9] Wang W F, Wu M J. Effect of silicon content and aging time on density, hardness, toughness and corrosion resistance of sintered 303LSC-Si stainless steels. Mater Sci Eng A, 2006, 425(1-2): 167 doi: 10.1016/j.msea.2006.03.050 [10] Meng F, Guo S J, Zhang H, et al. Effect of adding various metal powders respectively on properties of 316L stainless steel. Mater Sci Eng Powder Metall, 2006, 11(6): 341 doi: 10.3969/j.issn.1673-0224.2006.06.005孟飞, 果世驹, 张恒, 等. 添加金属粉末对粉末冶金316L不锈钢性能的影响. 粉末冶金材料科学与工程, 2006, 11(6): 341 doi: 10.3969/j.issn.1673-0224.2006.06.005 [11] Kazior J, Nykiel M, Pieczonka T, et al. Activated sintering of P/M duplex stainless steel powders. J Mater Process Technol, 2004, 157-158: 712 doi: 10.1016/j.jmatprotec.2004.07.140 [12] Ozkan Gülsoy H. Influence of nickel boride additions on sintering behaviors of injection moulded 17-4PH stainless steel powder. Scr Mater, 2005, 52(3): 187 doi: 10.1016/j.scriptamat.2004.09.032 [13] Liu Yan. Effects of fecrbsi pre-alloyed powder on the wear properties of diamond saws. Met Mater Metall Eng, 2007, 35(4): 10 doi: 10.3969/j.issn.1005-6084.2007.04.003刘燕. FeCrBSi预合金粉末对金刚石锯片磨损特性的影响. 金属材料与冶金工程, 2007, 35(4): 10 doi: 10.3969/j.issn.1005-6084.2007.04.003 [14] Zeng D L, Zhang H Q. Supersolidus liquid phase sintering. Powder Metall Ind, 1995(1): 6 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG199501001.htm曾德麟, 张怀泉. 超固相线液相烧结. 粉末冶金工业, 1995(1): 6 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG199501001.htm -

下载:

下载: