Study on microstructures and properties of high boron aluminum alloy prepared by powder metallurgy combined with hot rolling

-

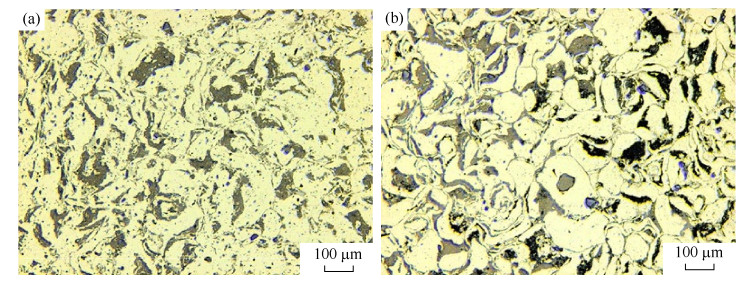

摘要: 采用粉末冶金结合热轧成形工艺制备含硼质量分数为7%与12%的中子屏蔽用高硼铝合金(Al-7% B与Al-12% B),并对不同工艺条件下铝硼合金的组织与性能进行研究。结果表明:在机械球磨5 min+放电等离子烧结条件下,Al-7% B合金中AlB2体积分数高于Al-12% B合金,且分布更加均匀。放电等离子烧结后进行热轧有利于提高试样的相对密度,减少硼粉团聚。在450℃固溶处理2 h,Al-7% B合金试样的拉伸强度和屈服强度达到峰值,分别为145.7 MPa和99.4 MPa。由10B面密度理论计算结果可知,厚度相近时,热轧后高硼铝合金10B面密度均可达到BoralTM水平。Abstract: High boron aluminum alloys for neutron shielding (Al-7%B and Al-12%B alloys by mass) were fabricated by powder metallurgy combined with hot rolling. The microstructures and properties of high boron aluminum alloys were investigated in different process conditions. In the results, the volume fraction of AlB2 particles in Al-7%B alloy compacts sintered by spark plasma sintering after ball milling for 5 min is higher than that of Al-12%B alloy, and the distribution of AlB2 particles shows more uniformly in Al-7%B alloy compacts. The hot rolling after spark plasma sintering is beneficial to increase the relative densities of compacts and decrease the agglomerations of boron powder in samples. The tensile and yield strengths of Al-7%B alloy quenched at 450℃ for 2 h reach 145.7 MPa and 99.4 MPa, respectively. According to the theoretical calculations, the areal densities of the hot rolled aluminum boron alloys reach the level of BoralTM.

-

Key words:

- powder metallurgy /

- hot rolling /

- solution treatment /

- aluminum boron alloy

-

表 1 铝合金粉末与烧结体物理性能

Table 1. Physical properties of powders and sintered Al alloy specimens

试样 厚度/ cm 密度/ (g·cm-3) 相对密度/ % 含氧质量分数/ % Al–7%B粉末 — — — 1.92 Al–7%B烧结体 0.415 2.268 85.29 1.47 Al–12%B粉末 — — — 1.79 Al–12%B烧结体 0.415 2.261 85.31 1.35 BoralTM 0.300 2.520 93.00 — 表 2 纯铝与高硼铝合金的力学性能

Table 2. Mechanical properties of pure Al and high boron aluminum alloys

试样 拉伸强度/ MPa 屈服强度/ MPa 伸长率/ % 纯Al 55.8±2.1 15.6±2.2 24.3±0.9 烧结Al–7%B 79.6±3.8 32.5±2.6 7.8±0.6 热轧Al–7%B 99.9±3.2 60.6±3.0 6.7±0.7 热处理Al–7%B 145.7±4.1 99.4±3.9 3.7±0.8 烧结Al–12%B 36.4±2.7 18.5±2.3 9.3±0.6 热轧Al–12%B 41.6±2.4 24.7±2.0 11.1±0.7 热处理Al–12%B 47.4±2.3 31.2±2.6 8.4±0.8 BoralTM 68.4 — 0.1 表 3 铝合金面密度

Table 3. Areal densities of aluminum alloys (10B)

试样 厚度/ cm 面密度/ (g·cm–2) 热轧Al–7%B 0.202 0.06 热轧Al–12%B 0.185 0.10 BoralTM 0.178~1.12 0.005~0.120 -

[1] Han Y, Chen F G, Yu W Y, et al. Investigation of the research status of neutron shielding materials. Mater Rev, 2015, 29(Suppl 2): 483 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2015S2120.htm韩毅, 陈法国, 于伟跃, 等. 中子屏蔽材料研究现状. 材料导报, 2015, 29(增刊2): 483 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2015S2120.htm [2] Mann K S. γ–Ray shielding behaviors of some nuclear engineering materials. Nucl Eng Technol, 2017, 49(4): 792 doi: 10.1016/j.net.2016.12.016 [3] Chen S D, Chen J C. Study reality and development prospect of lead-based nuclear shielding material. Mater Rev, 2011, 25(7): 58 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201113014.htm陈守东, 陈敬超. 铅基核屏蔽材料的研究现状及发展前景展望. 材料导报, 2011, 25(7): 58 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201113014.htm [4] Wu Y C, Wang M H, Huang Q Y, et al. Development status and prospects of lead-based reactors. Nucl Sci Eng, 2015, 35(2): 213 doi: 10.3969/j.issn.0258-0918.2015.02.004吴宜灿, 王明煌, 黄群英, 等. 铅基反应堆研究现状与发展前景. 核科学与工程, 2015, 35(2): 213 doi: 10.3969/j.issn.0258-0918.2015.02.004 [5] Tian J, Zhu B B, Wang Y, et al. Current situation and development trend of radiation cement. Environ Eng, 2014(7): 119 https://www.cnki.com.cn/Article/CJFDTOTAL-HJGC201407027.htm田键, 朱兵兵, 汪洋, 等. 防辐射水泥的现状及发展趋势. 环境工程, 2014(7): 119 https://www.cnki.com.cn/Article/CJFDTOTAL-HJGC201407027.htm [6] Yuan Q S. The Effect of Zr, Cr, Ni on the Microstructure of High Boron Steel[Dissertation]. Chengdu: Xihua University, 2009袁亲松. Zr、Cr、Ni对高硼钢组织的影响[学位论文]. 成都: 西华大学, 2009 [7] Gong X, Wang H Q, Fu M M, et al. Research development of high-strength Al–Cu–Mn series aluminum alloy used for aviation and aerospace. Hot Working Technol, 2015, 44(22): 6 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201522002.htm龚习, 王恒强, 付敏敏, 等. 航空航天用Al–Cu–Mn系高强铝合金的研究进展. 热加工工艺, 2015, 44(22): 6 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201522002.htm [8] Niu Z W, Huang J H, Xu F Z, et al. Current research status and prospect of brazing filler metals for aluminum and aluminum alloys. Chin J Nonferrous Met, 2016, 26(1): 77 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201601010.htm牛志伟, 黄继华, 许方钊, 等. 铝及铝合金钎焊用硬钎料的研究现状与展望. 中国有色金属学报, 2016, 26(1): 77 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201601010.htm [9] Sun Y, Ren J, Zhang Y S. Effect of solution treatment and two-step aging on microstructure and hardness for 7050 aluminum alloy. Heat Treat Met, 2016, 41(3): 25 doi: 10.3969/j.issn.1673-4971.2016.03.007孙燕, 任洁, 张艳姝. 固溶处理及双级时效对7050铝合金微观组织和硬度的影响. 金属热处理, 2016, 41(3): 25 doi: 10.3969/j.issn.1673-4971.2016.03.007 [10] Yang S J, Yang X. Progress in high-strength aluminum alloy research. Powder Metall Ind, 2010, 20(5): 47 doi: 10.3969/j.issn.1006-6543.2010.05.010杨守杰, 杨霞. 高强度铝合金的研究进展. 粉末冶金工业, 2010, 20(5): 47 doi: 10.3969/j.issn.1006-6543.2010.05.010 [11] Yu S, Lang L H, Wang G, et al. Research on numerical simulation of 2A12 aluminum alloy manufactured by hot isostatic pressing. Powder Metall Ind, 2016, 26(2): 17 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201602006.htm喻思, 郎利辉, 王刚, 等. 热等静压成形2A12铝合金粉末的数值模拟研究. 粉末冶金工业, 2016, 26(2): 17 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201602006.htm [12] Cui J H, Cai J P, Jia C C. Pitting corrosion of high strength aluminum alloys in salt spray test. J Chin Soc Corros Prot, 2010, 30(3): 197 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGFF201003006.htm崔继红, 蔡建平, 贾成厂. 盐雾环境下高强度铝合金的点蚀行为. 中国腐蚀与防护学报, 2010, 30(3): 197 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGFF201003006.htm [13] Machiels A, Lambert R. Handbook on Neutron Absorber Materials for Spent Nuclear Fuel Applications. Palo Alto: Electric Power Research Institute, 2005 [14] Ni Q L, Zheng W J, Song Z G, et al. Effect of boron content on microstructure and property of boron stainless steel. J Iron Steel Res, 2013, 25(6): 53 https://www.cnki.com.cn/Article/CJFDTOTAL-IRON201306011.htm佴启亮, 郑文杰, 宋志刚, 等. 硼含量对含硼不锈钢组织和性能的影响. 钢铁研究学报, 2013, 25(6): 53 https://www.cnki.com.cn/Article/CJFDTOTAL-IRON201306011.htm [15] Fan T, Liu B W, Sun Y R, et al. Study on wear resistance of Al2O3 particle reinforced Al matrix composites. Powder Metall Technol, 2015, 33(3): 186 doi: 10.3969/j.issn.1001-3784.2015.03.006范涛, 刘博文, 孙艳荣, 等. Al2O3颗粒增强铝基复合材料的耐磨性研究. 粉末冶金技术, 2015, 33(3): 186 doi: 10.3969/j.issn.1001-3784.2015.03.006 [16] Roy M N, Sinha A. Viscous synergy and antagonism and isentropic compressibility of ternary mixtures containing 1, 3-dioxolane, water and monoalkanols at 303.15 K. Fluid Phase Equilib, 2006, 243(1-2): 133 doi: 10.1016/j.fluid.2006.02.023 [17] Gan Y N, Lim Y S, Qiao L. Combustion of nanofluid fuels with the addition of boron and iron particles at dilute and dense concentrations. Combust Flame, 2012, 159(4): 1732 doi: 10.1016/j.combustflame.2011.12.008 [18] Guo L G, Song W L, Xie C S, et al. Characterization and thermal properties of carbon-coated aluminum nanopowders prepared by laser-induction complex heating in methane. Mater Lett, 2007, 61(14-15): 3211 doi: 10.1016/j.matlet.2006.11.035 [19] Kwon H, Estili M, Takagi K, et al. Combination of hot extrusion and spark plasma sintering for producing carbon nanotube reinforced aluminum matrix composites. Carbon, 2009, 47(3): 570 doi: 10.1016/j.carbon.2008.10.041 -

下载:

下载: