-

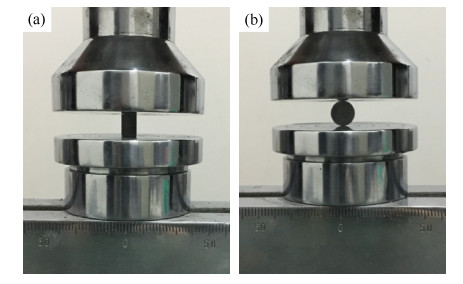

摘要: 通过单轴压缩实验、径向压缩(巴西圆盘)实验和冷模模压实验建立了基于密度相关修正Drucker-Prager Cap(DPC)的Ti-6Al-4V粉末压制本构模型,利用ABAQUS有限元仿真软件的二次开发用户子程序USDFLD对该本构模型进行了模拟验证。综合考虑压制过程中实验装置变形对实验数据的影响,通过空压校正实验控制实验误差,建立了更加准确的修正DPC模型。结果表明:修正DPC本构模型可很好地应用于Ti-6Al-4V粉末压制过程的仿真模拟;当上模冲压力较小时(< 50 MPa),模壁摩擦系数随上模冲压力的增加逐渐减小,当上模冲压力较大时(>50 MPa),模壁摩擦系数随上模冲压力的增加而基本趋于稳定。

-

关键词:

- Ti-6Al-4V粉末 /

- Drucker-Prager Cap模型 /

- 粉末压制 /

- 数值模拟

Abstract: The density-dependent modified Drucker-Prager Cap (DPC) constitutive model of Ti-6Al-4V powders for cold die compaction was established by uniaxial compression test, diametrical compression test (Brazilian disc experiment), and die compression test in this paper, the constitutive model was verified by the user subroutine USDFLD in secondary development based on finite element software ABAQUS. Considering the influence of device deformation on experimental data in compaction process, the experimental error was controlled by calibration experiment, and the more accurate modified DPC model was established. The results show that, the modified DPC model of Ti-6Al-4V powders for cold die compaction can be accurately used in the simulation analysis of Ti-6Al-4V powders compaction. In addition, the wall friction decreases gradually with the increase of the top punch pressure when the top punch pressure is lower than 50 MPa; while the wall friction tends to be stable with the increase of the top punch pressure, when the top punch pressure is higher than 50 MPa.-

Key words:

- Ti-6Al-4V powders /

- Drucker-Prager Cap model /

- powder compaction /

- numerical modeling

-

图 7 修正DPC模型参数、弹性参数与相对密度的关系以及摩擦系数与上模冲压力的关系:(a)内聚力,d;(b)摩擦角,β;(c)演化参数,pa;(d)静态屈服应力,pb;(e)偏心距,R;(f)弹性模量,E;(g)泊松比,υ;(h)摩擦系数,μ

Figure 7. Relationship of modified DPC model parameters, elastic properties, and relative density and the variation of friction coefficient with top punch pressure: (a) cohesion, d; (b) friction angle, β; (c) evolution parameter, pa; (d) hydrostatic yield stress, pb; (e) cap excentricity, R; (f) Young's modulus, E; (g) Poisson's ratio, υ; (h) friction coefficient, μ

表 1 Ti–6Al–4V粉末化学成分表(质量分数)

Table 1. Chemical composition of Ti–6Al–4V powders

% Al V Fe C N H O Ti 6.00 3.90 0.05 0.02 0.180 0.039 0.20 余量 -

[1] Wei W H, Wang L Z, Chen T, et al. Study on the flow properties of Ti–6Al–4V powders prepared by radio-frequency plasma spheroidization. Adv Powder Technol, 2017, 28(9): 2431 doi: 10.1016/j.apt.2017.06.025 [2] Liu C, Kong X J, Wu S W, et al. Research progress on metal injection molding of titanium and titanium alloys. Powder Metall Technol, 2017, 35(2): 150 doi: 10.3969/j.issn.1001-3784.2017.02.012刘超, 孔祥吉, 吴胜文, 等. 钛及钛合金金属粉末注射成形技术的研究进展. 粉末冶金技术, 2017, 35(2): 150 doi: 10.3969/j.issn.1001-3784.2017.02.012 [3] Huang B. Research on Difficult-to-Cut Materials Processing Technology Based on Titanium [Dissertation]. Nanjing: Nanjing University of Science and Technology, 2015黄蓓. 基于钛合金的难加工材料切削加工工艺研究[学位论文]. 南京: 南京理工大学, 2015 [4] Wang H Y, Guo Z M, Lu B X, et al. Industrialized production technology of powder metallurgy (PM) titanium and titanium alloy. Titanium Ind Prog, 2017, 34(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-TGYJ201701001.htm王海英, 郭志猛, 芦博欣, 等. 钛合金粉末冶金工业化生产技术. 钛工业进展, 2017, 34(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-TGYJ201701001.htm [5] Wang J, Li C X, Ruan X Y. Modeling approach for numerical simulation of powdered metal compacting process. Mech Sci Technol, 2000, 19(3): 436 doi: 10.3321/j.issn:1003-8728.2000.03.034汪俊, 李从心, 阮雪榆. 粉末金属压制过程数值模拟建模方法. 机械科学与技术, 2000, 19(3): 436 doi: 10.3321/j.issn:1003-8728.2000.03.034 [6] Biswas K. Comparison of various plasticity models for metal powder compaction processes. J Mater Process Technol, 2005, 166(1): 107 doi: 10.1016/j.jmatprotec.2004.08.006 [7] Bierwisch C, Kraft T, Riedel H, et al. Die filling optimization using three-dimensional discrete element modeling. Powder Technol, 2009, 196(2): 169 doi: 10.1016/j.powtec.2009.07.018 [8] Yan S W, Huang S Y, Hu J H, et al. Development and application of numerical simulation in powder metallurgy manufacturing. Powder Metall Technol, 2017, 35(1): 57 doi: 10.3969/j.issn.1001-3784.2017.01.010颜士伟, 黄尚宇, 胡建华, 等. 数值仿真技术在粉末冶金零件制造中的应用及研究进展. 粉末冶金技术, 2017, 35(1): 57 doi: 10.3969/j.issn.1001-3784.2017.01.010 [9] Drucker D C, Gibson R E, Henkel D J. Soil mechanics and work hardening theories of plasticity. Am Soc Civ Eng, 1957, 122: 338 doi: 10.1061/TACEAT.0007430 [10] Sinka I C, Cunningham J C, Zavaliangos A. The effect of wall friction in the compaction of pharmaceutical tablets with curved faces: a validation study of the Drucker–Prager Cap model. Powder Technol, 2003, 133(1-3): 33 doi: 10.1016/S0032-5910(03)00094-9 [11] Reiterer M, Kraft T, Janosovits U, et al. Finite element simulation of cold isostatic pressing and sintering of SiC components. Ceram Int, 2004, 30(2): 177 doi: 10.1016/S0272-8842(03)00086-5 [12] Zhang B S, Jain M, Zhao C H, et al. Experimental calibration of density-dependent modified Drucker–Prager/Cap model using an instrumented cubic die for powder compact. Powder Technol, 2010, 204(1): 27 doi: 10.1016/j.powtec.2010.07.003 [13] Hu J Z, Li D R, Zhou B, et al. Study on numerical simulation of W–Cu20 powder rolling based on Drucker–Prager/Cap model. Powder Metall Technol, 2017, 35(4): 249 doi: 10.19591/j.cnki.cn11-1974/tf.2017.04.002胡建召, 李达人, 周冰, 等. 基于Drucker–Prager/Cap模型的W–Cu20粉末轧制数值模拟. 粉末冶金技术, 2017, 35(4): 249 doi: 10.19591/j.cnki.cn11-1974/tf.2017.04.002 [14] Zhou M C, Huang S Y, Hu J H, et al. A density-dependent modified Drucker–Prager Cap model for die compaction of Ag57.6–Cu22.4–Sn10–In10 mixed metal powders. Powder Technol, 2017, 305: 183 doi: 10.1016/j.powtec.2016.09.061 [15] Zhou R. Study on Residual Stress and Cracks Damage of Powder Metallurgy Compacts [Dissertation]. Tianjin: Tianjin University, 2013周蕊. 粉末冶金压坯残余应力与裂纹损伤研究[学位论文]. 天津: 天津大学, 2013 [16] Lamarche K, Buckley D, Hartley R, et al. Assessing materials' tablet compaction properties using the Drucker–Prager Cap model. Powder Technol, 2014, 267: 208 doi: 10.1016/j.powtec.2014.06.050 [17] Almanstötter J. A modified Drucker–Prager Cap model for finite element simulation of doped tungsten powder compaction. Int J Refract Met Hard Mater, 2015, 50: 290 doi: 10.1016/j.ijrmhm.2015.02.005 [18] Han L H, Elliott J A, Bentham A C, et al. A modified Drucker–Prager Cap model for die compaction simulation of pharmaceutical powders. Int J Solids Struct, 2008, 45(10): 3088 doi: 10.1016/j.ijsolstr.2008.01.024 [19] Zhou M C, Huang S Y, Hu J H, et al. Experiment and finite element analysis of compaction densification mechanism of Ag–Cu–Sn–In mixed metal powder. Powder Technol, 2017, 313: 68 doi: 10.1016/j.powtec.2017.03.015 -

下载:

下载: