Study on the properties of diamond saw blades prepared by Cu-based pre-alloyed powders

-

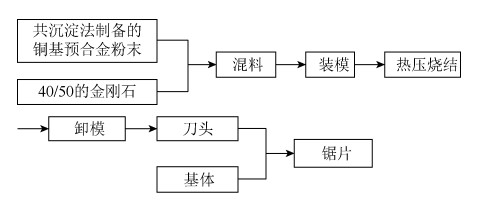

摘要: 采用共沉淀法制备了不同铜铁配比(质量比:45:35、50:30、55:25)的铜基预合金粉末,利用真空热压法烧结得到含金刚石的铜基结合剂刀头,通过激光焊接的方法制备出铜基结合剂金刚石锯片,研究了铜基预合金粉末中铜铁含量(质量分数)对金刚石锯片性能的影响。利用扫描电子显微镜观察锯片断面的显微组织形貌,并测量不同铜铁含量锯片的硬度和磨损量。结果表明:在三种配比中,当铜和铁质量比为50:30时,铜基结合剂与金刚石间的结合最佳,锯片性能最好,硬度最高(HRB 118),锯片的磨损量最少(1.16 g)。Abstract: The Cu-based pre-alloy powders were prepared by coprecipitation method in different ratios of Cu and Fe by mass (45:35, 50:30, 55:25), the Cu-based bonded diamond segments were fabricated by hot pressing method, and the Cu-based bonded diamond saw blades were manufactured by laser-welded method. The effects of Cu and Fe contents by mass on the properties of diamond saw blades prepared by Cu-based pre-alloyed powders were investigated. The fracture morphologies of saw blade surfaces were characterized by scanning electron microscope, and the hardness and abrasion loss of diamond saw blades were tested. The results show that, when the ratio of Cu and Fe by mass is 50:30, the combination between Cu-based bond and diamond is the optimal, the saw blades show the best performance as the maximum hardness of HRB 118 and the minimum abrasion loss of 1.16 g.

-

Key words:

- Cu-based pre-alloyed powders /

- diamond saw blades /

- metal bond /

- fracture morphology /

- properties

-

表 1 实验用锯片配方(质量分数)

Table 1. Formula of saw blades

% 锯片编号 Cu Fe Sn Ni 1# 45 35 10 10 2# 50 30 10 10 3# 55 25 10 10 表 2 金刚石锯片切割性能

Table 2. Cutting performances of diamond saw blades

锯片编号 Cu: Fe质量比 切割状态 锯片失重,Δm / g 锯切面积,S / m2 1# 45:35 顺利切割 2.10 0.12 2# 50:30 顺利切割 1.16 0.12 3# 55:25 顺利切割 2.24 0.12 -

[1] Shen S, Song Y Q, Wang L M, et al. Application of pre-alloyed powders for diamond tools. Powder Metall Ind, 2006, 16(6): 2 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG200606015.htm申思, 宋月清, 汪礼敏, 等. 预合金粉末在金刚石工具中的应用. 粉末冶金工业, 2006, 16(6): 2 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG200606015.htm [2] Yu Y, Huang S K, Zeng G Y. The production status quo and development tendency of pre-alloy powder used for diamond tools. Met Mater Metall Eng, 2010, 38(5): 49 doi: 10.3969/j.issn.1005-6084.2010.05.013余勇, 黄圣坤, 曾归余. 金刚石工具用预合金粉末生产现状及发展趋势. 金属材料与冶金工程, 2010, 38(5): 49 doi: 10.3969/j.issn.1005-6084.2010.05.013 [3] Wang C, Zhang X F, Wang C F. Current research situation and development of Cu-based diamond tools made by powder metallurgy. Powder Metall Ind, 2012, 30(2): 140 doi: 10.3969/j.issn.1001-3784.2012.02.011王闯, 张效芬, 王长福. 粉末冶金Cu基金刚石工具的研究现状及进展. 粉末冶金技术, 2012, 30(2): 140 doi: 10.3969/j.issn.1001-3784.2012.02.011 [4] Xu Q, Liu Y B, Xu L, et al. Properties of Fe-based pre-alloy powders with different contents. Powder Metall Technol, 2017, 35(2): 103 doi: 10.3969/j.issn.1001-3784.2017.02.005徐强, 刘一波, 徐良, 等. 不同配比铁基预合金粉的胎体性能研究. 粉末冶金技术, 2017, 35(2): 103 doi: 10.3969/j.issn.1001-3784.2017.02.005 [5] Liu Y B, Xu Q, Xu L. Characteristics status analysis and development trend of metal powders for diamond tools. Powder Metall Ind, 2017, 27(4): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201704001.htm刘一波, 徐强, 徐良. 金刚石工具用金属粉末的特性、现状分析和发展趋势. 粉末冶金工业, 2017, 27(4): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201704001.htm [6] Xu H X, Ma H Q, Luo X Y, et al. Atomized prealloyed powders and it's application in diamond tools. Diamond Abras Eng, 2004(1): 45 doi: 10.3969/j.issn.1006-852X.2004.01.012徐浩翔, 麻洪秋, 罗锡裕, 等. 雾化预合金胎体粉末的制备及其在金刚石工具中的应用. 金刚石与磨料磨具工程, 2004(1): 45 doi: 10.3969/j.issn.1006-852X.2004.01.012 [7] Chu Z Q, Guo X Y, Liu D H, et al. Application of pre-alloyed powders for diamond tools by ultrahigh pressure water atomization. Trans Nonferrous Met Soc China, 2016, 26(10): 2665 doi: 10.1016/S1003-6326(16)64393-5 [8] Ding T R. Preparation and Application of Pre-alloyed Powder for Diamond Tools[Dissertation]. Zhengzhou: Zhengzhou Research Institute of Mechanical Engineering, 2011丁天然. 金刚石工具用预合金粉末的制备及其应用[学位论文]. 郑州: 郑州机械研究所, 2011 [9] Xie C D, Chen W. Study on production process of water atomized copper–0.3 lanthanum powders. Powder Metall Technol, 2011, 29(4): 279 http://pmt.ustb.edu.cn/article/id/fmyjjs201104008解传娣, 陈文. 水雾化Cu–0.3La预合金粉制备工艺研究. 粉末冶金技术, 2011, 29(4): 279 http://pmt.ustb.edu.cn/article/id/fmyjjs201104008 [10] Chu Z Q, Guo X Y, Zhang L, et al. Effect of super high pressure water atomization parameters on diameter and micrograph of diamond matrix prealloy powders. Mater Sci Eng Powder Metall, 2015, 20(5): 808 doi: 10.3969/j.issn.1673-0224.2015.05.023储志强, 郭学益, 张立, 等. 超高压水雾化工艺参数对金刚石胎体用预合金粉末粒度与形貌的影响. 粉末冶金材料科学与工程, 2015, 20(5): 808 doi: 10.3969/j.issn.1673-0224.2015.05.023 [11] Zhao W D, Xu J, Song Y Q, et al. Study on superfine pre-alloying powder for diamond tools by Co-precipitation–decomposition method. Powder Metall Technol, 2010, 28(2): 130 http://pmt.ustb.edu.cn/article/id/fmyjjs201002011赵文东, 徐骏, 宋月清, 等. 共沉淀–共还原法制备金刚石工具用超细预合金粉末的研究. 粉末冶金技术, 2010, 28(2): 130 http://pmt.ustb.edu.cn/article/id/fmyjjs201002011 [12] Xie D L, Wan L, Liu Z H. Low-temperature hot press sintering of Fe–Cu based pre-alloyed powder manufactured by co-precipitation method. Mater Sci Eng Powder Metall, 2015, 20(1): 93 doi: 10.3969/j.issn.1673-0224.2015.01.015谢德龙, 万隆, 刘志环. 共沉淀法制备Fe–Cu基预合金粉的低温热压烧结. 粉末冶金材料科学与工程, 2015, 20(1): 93 doi: 10.3969/j.issn.1673-0224.2015.01.015 [13] Xiang B, He Y H, Xie Z G. Preparation of prealloyed powder for diamond tools by coprecipitation–thermal decomposition method. Powder Metall Technol, 2008, 26(1): 44 http://pmt.ustb.edu.cn/article/id/fmyjjs200801011向波, 贺跃辉, 谢志刚. 共沉淀–热分解法制备金刚石工具用预合金粉. 粉末冶金技术, 2008, 26(1): 44 http://pmt.ustb.edu.cn/article/id/fmyjjs200801011 [14] Huang R, Chen S Q. Preparation of Cu–Sn prealloyed powder by oxalate co-precipitation method. Mater Sci Eng Powder Metall, 2010, 15(5): 525. doi: 10.3969/j.issn.1673-0224.2010.05.021黄蓉, 陈仕奇. 草酸盐共沉淀法制备Cu–Sn预合金粉末. 粉末冶金材料科学与工程, 2010, 15(5): 525). doi: 10.3969/j.issn.1673-0224.2010.05.021 [15] Xiao C J, Dou Z Q. Preparation of ultrafine Cu–Fe–Sn–Ni Cu-matrix bonded pre-alloyed powder by co-precipitation method and its flexural strength of sintered matrix. Mater Sci Eng Powder Metall, 2018, 23(3): 246 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201803003.htm肖长江, 窦志强. 共沉淀法制备超细Cu–Fe–Sn–Ni铜基预合金粉及其烧结胎体的抗弯强度. 粉末冶金材料科学与工程, 2018, 23(3): 246 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201803003.htm [16] Xiao C J, Li X L, Dou Z Q. Effect of Ti on the wettability and the holding force in diamond/Al–Ti alloy. J Synth Cryst, 2017, 46(10): 2045 doi: 10.3969/j.issn.1000-985X.2017.10.032肖长江, 栗晓龙, 窦志强. Ti对Al–Ti合金与金刚石的润湿性和把持力的影响. 人工晶体学报, 2017, 46(10): 2045 doi: 10.3969/j.issn.1000-985X.2017.10.032 -

下载:

下载: