Preparation and mechanical properties of graphene reinforced-Al7075 composite by semi-solid sintering

-

摘要: 通过球磨混粉+半固态烧结法成功制备出质量分数为0.5%的石墨烯/7075铝基复合材料,通过扫描电子显微镜、能谱分析仪和室温拉伸力学性能测试等手段,对石墨烯/7075铝基复合材料的显微组织及力学性能进行了研究。结果表明:复合材料中的石墨烯纳米片均匀的分散在7075铝合金基体中,相比于未添加石墨烯的7075铝合金基体,复合材料的密度有所下降,维式硬度和抗拉强度则分别提高了14%和32%,延伸率无明显变化。Abstract: Graphene reinforced-Al7075 composite was successfully prepared through ball milling mixing powder and semi solid sintering method. The influences of graphene on the microstructures and mechanical properties of Al7075 composite were investigated by scanning electron microscope (SEM), energy dispersive spectrometer (EDS), and static tensile tests. The results show that, the graphene nanoflakes are well dispersed in Al7075 matrix. Compared to the Al7075 matrix without the addition of graphene, the density of graphene reinforced-Al7075 composite decreases, the Vickers hardness and tensile strength increase by 14% and 32%, respectively, and the elongation shows a slight drop.

-

Key words:

- aluminum matrix composite /

- semi-solid sintering /

- graphene /

- mechanical properties

-

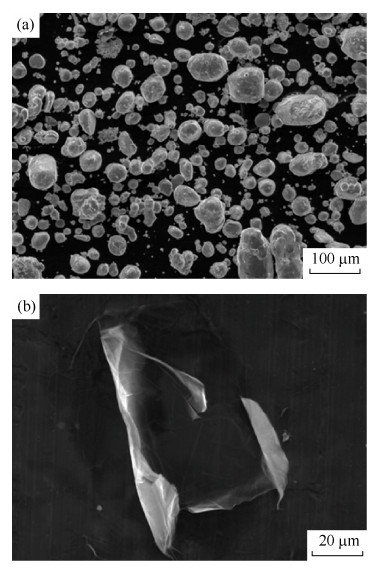

图 2 半固态烧结7075铝基复合材料显微组织形貌与能谱分析:(a)未添加石墨烯Al7075铝合金;(b)添加质量分数0.5%石墨烯/7075铝基复合材料(低倍);(c)添加质量分数0.5%石墨烯/7075铝基复合材料(高倍);(d)A点处能谱分析

Figure 2. SEM images and energy dispersive spectrometer (EDS) analysis of graphene reinforced-Al7075 composite by semi-solid sintering: (a) Al7075 composite without graphene; (b) Al7075 composite with 0.5% graphene by mass (low magnification); (c) Al7075 composite with 0.5% graphene by mass (high magnification); (d) EDS analysis at point A

-

[1] Williams J C, Starke E A Jr. Progress in structural materials for aerospace systems. Acta Mater, 2003, 51(19): 5775 doi: 10.1016/j.actamat.2003.08.023 [2] Yan S J, Chen X, Hong Q H, et al. Graphite reinforced aluminum matrix nanocomposites. J Aeronaut Mater, 2016, 36(3): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201603007.htm燕绍九, 陈翔, 洪起虎, 等. 石墨烯增强铝基纳米复合材料研究进展. 航空材料学报, 2016, 36(3): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201603007.htm [3] Qi T J, Yu Z M, Xu Z P, et al. Research progress in graphene reinforced aluminum matrix composite. Hot Work Technol, 2016, 45(10): 6 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201610003.htm齐天娇, 俞泽民, 许志鹏, 等. 石墨烯增强铝基复合材料的研究进展. 热加工工艺, 2016, 45(10): 6 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201610003.htm [4] Lu N N, Xu L, Li C Y, et al. Research progress on preparation technology of aluminum matrix composites reinforced by grapheme. Powder Metall Technol, 2017, 35(4): 310 doi: 10.19591/j.cnki.cn11-1974/tf.2017.04.012鲁宁宁, 许磊, 历长云, 等. 石墨烯增强铝基复合材料制备技术研究进展. 粉末冶金技术, 2017, 35(4): 310 doi: 10.19591/j.cnki.cn11-1974/tf.2017.04.012 [5] Lee C, Wei X, Kysar J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science, 2008, 321(5887): 385 doi: 10.1126/science.1157996 [6] Bolotin K I, Sikes K J, Jiang Z, et al. Ultrahigh electron mobility in suspended graphene. Solid State Commun, 2008, 146(9-10): 351 doi: 10.1016/j.ssc.2008.02.024 [7] Balandin A A, Ghosh S, Bao W, et al. Superior thermal conductivity of single-layer graphene. Nano Lett, 2008, 8(3): 902 doi: 10.1021/nl0731872 [8] Yolshina L A, Muradymov R V, Korsun I V, et al. Novel aluminum–graphene and aluminum–graphite metallic composite materials: Synthesis and properties. J Alloys Compd, 2016, 663: 449 doi: 10.1016/j.jallcom.2015.12.084 [9] Li D S, Wu W Z, Qin Q H, et al. Microstructure and mechanical properties of graphene/Al composites. Chin J Nonferrous Met, 2015, 25(6): 1498 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201506012.htm李多生, 吴文政, Qin Qing-hua, 等. 石墨烯/Al复合材料的微观结构及力学性能. 中国有色金属学报, 2015, 25(6): 1498 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201506012.htm [10] Bastwros M, Kim Y G, Zhu C, et al. Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering. Composites Part B, 2014, 60(1): 111 https://www.sciencedirect.com/science/article/abs/pii/S1359836813007737 [11] Jeon C H, Jeong Y H, Seo J J, et al. Material properties of graphene/aluminum metal matrix composites fabricated by friction stir processing. Int J Precis Eng Manuf, 2014, 15(6): 1235 doi: 10.1007/s12541-014-0462-2 [12] Guan R G, Lian C, Zhao Z Y, et al. Study on preparation of graphene and Al–graphene composite. Rare Met Mater Eng, 2012, 41(Suppl 2): 607 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE2012S2147.htm管仁国, 连超, 赵占勇, 等. 石墨烯铝基复合材料的制备及其性能. 稀有金属材料与工程, 2012, 41(增刊2): 607 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE2012S2147.htm [13] Li J L, Xiong Y C, Wang X D, et al. Microstructure and tensile properties of bulk nanostructured aluminum/graphene composites prepared via cryomilling. Mater Sci Eng A, 2015, 626: 400 doi: 10.1016/j.msea.2014.12.102 [14] Yan S J, Dai S L, Zhang X Y. Investigating aluminum alloy reinforced by graphene nanoflakes. Mater Sci Eng A, 2014, 612: 440 doi: 10.1016/j.msea.2014.06.077 [15] Liu J, Khan U, Coleman J, et al. Graphene oxide and graphene nanosheet reinforced aluminium matrix composites: Powder synthesis and prepared composite characteristics. Mater Des, 2016, 94: 87 doi: 10.1016/j.matdes.2016.01.031 [16] Zhang D D, Zhan Z J. Progress in research on mechanical properties of graphite/metal composites. J Mater Eng, 2016, 44(5): 112 https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC201605017.htm张丹丹, 战再吉. 石墨烯/金属复合材料力学性能的研究进展. 材料工程, 2016, 44(5): 112 https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC201605017.htm [17] Rashad M, Pan F S, Yu Z W, et al. Investigation on microstructural, mechanical and electrochemical properties of aluminum composites reinforced with graphene nanoplatelets. Prog Nat Sci, 2015, 25(5): 460 doi: 10.1016/j.pnsc.2015.09.005 [18] Wang J Y, Li Z Q, Fan G L, et al. Reinforcement with graphene nanosheets in aluminum matrix composites. Scr Mater, 2012, 66(8): 594 doi: 10.1016/j.scriptamat.2012.01.012 -

下载:

下载: