Research on microstructure characterization in residual dendrite zones of FGH96 alloy with gradient microstructure

-

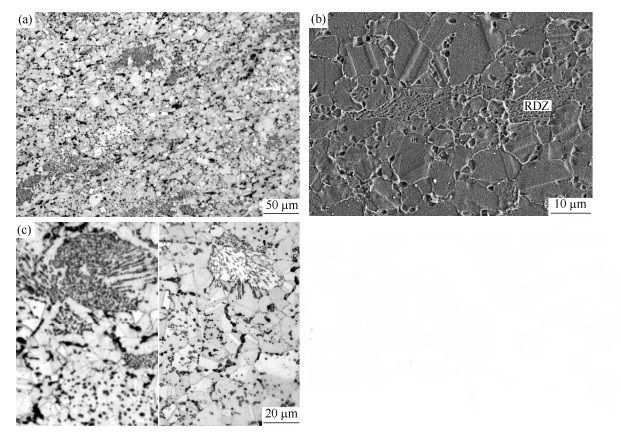

摘要: 采用梯度热处理工艺制备了具有梯度组织结构的FGH96合金亚尺寸盘坯, 对盘坯存在的残留枝晶区组织进行了研究。结果表明, 残留枝晶区实质上是一种γ′相未完全再结晶的组织区, 其呈区域性不均匀的分布于盘芯部位。残留枝晶区的形成与粉末颗粒冷凝组织的遗传性及未充分变形再结晶密切相关, 通过采用合适的热加工和固溶热处理工艺可以消除这种组织不均匀性。Abstract: The subscale FGH96 alloy disk with the gradient microstructure was prepared using gradient heat treatment. Microstructure characterization of residual dendrite zones was investigated. The results show that, the residual dendrite zone of FGH96 alloy disk is an incomplete recrystallization zone where γ′ phases exhibit the uneven distribution in disk core. The formation of residual dendrite zone is closely related to the solidification heredity of powder particles and incomplete deformation recrystallization, the inhomogeneity in residual dendrite zone can be eliminated by the suitable hot working and solution heat treatment.

-

表 1 FGH96合金化学成分(质量分数)

Table 1. Chemical composition of FGH96 alloy

% Co Cr Mo W Al Ti Nb B Zr C Ni 12.9 15.8 4.0 4.0 2.2 3.7 0.8 0.011 0.036 0.03 余量 表 2 残留枝晶区和等轴晶粒区γ′相析出特征

Table 2. Precipitation characteristics ofγ′ precipitates in RDZ and EGZ

析出特征 初始γ′相 二次γ′相 三次γ′相 梯度组织热处理 亚固溶处理 残留枝晶区 形状 简单枝晶,不规则方形 蝶形,不规则方形 圆角方形 球形 尺寸 0.2~1.0μm 60~180nm 30~60nm 10~30nm 颗粒密度 高 低 高 低 等轴晶粒区 形状 不规则方形 带突起的方形 球形 球形 尺寸 1~3μm 70~200nm 30~50nm < 30nm 颗粒密度 低 高 低 高 -

[1] Tian G F, Wang Y, Yang J, et al. Thermodynamic calculation on equilibrium precipitated phases in P/Mnickel-base superalloy. Powder Metall Technol, 2012, 30(4): 243 doi: 10.3969/j.issn.1001-3784.2012.04.001田高峰, 汪煜, 杨杰, 等. Ni基粉末冶金高温合金平衡析出相的热力学研究. 粉末冶金技术, 2012, 30(4): 243 doi: 10.3969/j.issn.1001-3784.2012.04.001 [2] Tian G F, Jia C C, Liu J T, et al. Experimental and simulation on the grain growth of P/M nickel-base superalloy during the heat treatment process. Mater Des, 2009(30): 433. http://www.sciencedirect.com/science/article/pii/S0261306908002598 [3] Tian G F, Wen Y, Jia C C, et al. Effect of cooling rate from solution heat treatment on theγ′precipitation behaviors in a Ni-base PM superlloy. J Univ Sci Technol Beijing, 2008, 15(6): 729. doi: 10.1016/S1005-8850(08)60278-9 [4] Hu B F, Tian G F, Jia C C, et al. Development in double-properties turbine disk of P/M superalloy. J Aeronaut Mater, 2007, 27(4): 80 doi: 10.3969/j.issn.1005-5053.2007.04.017胡本芙, 田高峰, 贾成厂, 等. 双性能粉末高温合金涡轮盘的研究进展. 航空材料学报, 2007, 27(4): 80 doi: 10.3969/j.issn.1005-5053.2007.04.017 [5] Gayda J, Gabb T P, Kantzos P T. Heat Treatment Devices and Method of Operation Thereof to Produced Dual Microstructure Superalloy Disks: US Patent, 6660110B1.2003‒12‒9. [6] Zhou X M, Tang D Z, Wang W X, et al. Effect of SiO2non-metal inclusion on micro-mechanical behavior of nickel-base P/M superalloy. J Aeronaut Mater, 2006, 26(3): 1 doi: 10.3969/j.issn.1005-5053.2006.03.001周晓明, 唐定中, 汪武祥, 等. SiO2非金属夹杂物对镍基粉末高温合金微观力学行为的影响. 航空材料学报, 2006, 26(3): 1 doi: 10.3969/j.issn.1005-5053.2006.03.001 [7] Bai Q, Lin J G, Tian G F, et al. Review and analysis of powder prior boundary(PPB)formation in powder metallurgy processes for nickel-based super alloys. J Powder Metall Min, 2015(4): 127. http://www.researchgate.net/publication/282411478_Review_and_Analysis_of_Powder_Prior_Boundary_PPB_Formation_in_Powder_Metallurgy_Processes_for_Nickel-based_Super_Alloys [8] Tian G F. Study on γ′Precipitation Behavior and Strengthen Responses in FGH96 Alloy Disc with a Dual Grain Structure[Dissertation]. Beijing: University of Science and Technology Beijing, 2009田高峰. FGH96合金双晶粒组织盘γ′相析出和强化研究, 北京: 北京科技大学, 2009 [9] Hu B F, Chen H M, Song D, et al. Research on MC type carbide in nickel-based superalloy powders during rapid solidification. Acta Metall Sin, 2005, 41(10): 1042 doi: 10.3321/j.issn:0412-1961.2005.10.007胡本芙, 陈焕铭, 宋铎, 等. 镍基高温合金快速凝固粉末颗粒中MC型碳化物相的研究. 金属学报, 2005, 41(10): 1042 doi: 10.3321/j.issn:0412-1961.2005.10.007 [10] Cotterill P, Mould P R. Recrystallization and Grain Growth in Metals. London: Surrey University Press, 1976. [11] Lü Y. Forging Technology. Beijing: China Machine Press, 1995吕炎. 锻造工艺学. 北京: 机械工业出版社, 1995 [12] Li C G, Fu H Z, Yu Q. Aerospace Materials. Beijing: National Defense Industry Press, 2002李成功, 傅恒志, 于翘. 航空航天材料. 北京: 国防工业出版社, 2002 -

下载:

下载: