Friction and wear properties of magnesium matrix composites reinforced by tungsten-coated carbon nanotubes

-

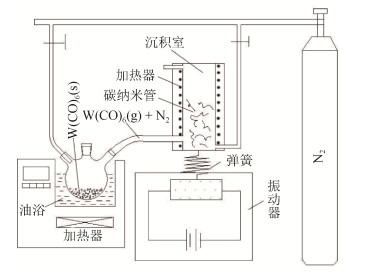

摘要: 以羰基钨为前驱体, 采用金属有机化学气相沉积在碳纳米管表面镀覆了金属钨, 利用磁力搅拌混粉和放电等离子体烧结制备了镀钨碳纳米管增强镁基复合材料((W-CNTs) /Mg), 研究了W-CNTs质量分数对复合材料摩擦磨损性能的影响。结果表明: W-CNTs的加入可对镁基体起到降低摩擦系数、减少磨损量的作用; 当W-CNTs质量分数为0.75%时, 复合材料的摩擦系数和磨损量均最小, 分别较纯镁降低了43.7%和71.4%;增加或降低复合材料中的W-CNTs质量分数, 材料的摩擦系数、磨损量均将增大。(W-CNTs) /Mg复合材料的摩擦磨损性能高于CNTs/Mg复合材料。Abstract: The tungsten were coated on the surface of carbon nanotubes (CNTs) by metal organic chemical vapor deposition (MOCVD) using hexacarbonyltungsten as the precursor, and the magnesium matrix composites reinforced by tungsten-coated carbon nanotubes ((W-CNTs) /Mg) were prepared by the combination of magnetic stirring (MS) and spark plasma sintering (SPS) processes. The influences of W-CNTs contents by mass on friction and wear properties of the composites were studied. The results show that, W-CNTs can effectively reduce the friction coefficient and wear loss of magnesium matrix. Compared with the pure magnesium, the friction coefficient and wear loss of 0.75% (W-CNTs) /Mg composites by mass are reduced by 43.7% and 71.4%, respectively; both the friction coefficient and the wear loss of Mg composites increase by increasing or decreasing W-CNTs contents. (W-CNTs) /Mg composites have the higher friction and wear properties than those of CNTs/Mg composites.

-

Key words:

- carbon nanotubes /

- tungsten coating /

- magnesium matrix composites /

- friction /

- wear

-

图 8 (W-CNTs) /Mg复合材料磨损表面形貌与W-CNTs质量分数关系: (a) 纯镁; (b) 0.25%W-CNTs; (c) 0. 7 5%W-CNTs; (d) 1. 2 5%W-CNTs; (e) 1.75%W-CNTs

Figure 8. Relationship between wear morphologies and W-CNTs contents by mass of (W-CNTs) /Mg composites: (a) pure Mg; (b) 0.25%W-CNTs; (c) 0. 7 5%W-CNTs; (d) 1. 2 5%W-CNTs; (e) 1.75%W-CNTs

表 1 摩擦磨损实验工艺参数

Table 1. Process parameters of friction and wear test

对磨材料 磨球直径/mm 摩擦回转半径/mm 主轴转速/(r·min-1) Si3N4 5 4 480 -

[1] Iijima S. Helical microtubules of graphitic carbon. Nature, 1991, 354: 56. doi: 10.1038/354056a0 [2] Pulickel M A, James M T. Nanotube composites. Nature, 2007, 447: 1066. doi: 10.1038/4471066a [3] Wong E W, Sheehan P E, Liebei C M. Nanobeam mechanics: Elasticity, strength, and toughness of nanorods and nanotubes. Science, 1997, 277: 1971. doi: 10.1126/science.277.5334.1971 [4] Chen X, Fu G S, Qian K W. Research status and development trend of magnesium matrix composites. Mech Electr Technol, 2003(Suppl 1): 74 https://www.cnki.com.cn/Article/CJFDTOTAL-JDJS2003S1012.htm陈晓, 傅高升, 钱匡武. 镁基复合材料的研究现状和发展趋势. 机电技术, 2003(增刊1): 74 https://www.cnki.com.cn/Article/CJFDTOTAL-JDJS2003S1012.htm [5] Wu Q, Jia C C, Nie J H. The mechanical and electrical properties of magnesium matrix composites reinforced by tungsten-coated carbon nanotubes. Powder Metall Technol, 2012, 30(3): 171 doi: 10.3969/j.issn.1001-3784.2012.03.003吴琼, 贾成厂, 聂俊辉. 镀W碳纳米管增强Mg基复合材料的力学和电学性能. 粉末冶金技术, 2012, 30(3): 171 doi: 10.3969/j.issn.1001-3784.2012.03.003 [6] Qin C, Shi X, Bai S Q, et al. High temperature electrical and thermal properties of the bulk carbon nanotube prepared by SPS. Mater Sci Eng A, 2006, 420(1-2): 208. doi: 10.1016/j.msea.2006.01.055 [7] Shen J L, Li S N, Yu T Q, et al. Study on the mechanical properties and strengthening mechanism of magnesium matrix composite by powder metallurgy. Foundry Technol, 2005, 26(4): 309 doi: 10.3969/j.issn.1000-8365.2005.04.016沈金龙, 李四年, 余天庆, 等. 粉末冶金法制备镁基复合材料的力学性能和增强机理研究. 铸造技术, 2005, 26(4): 309 doi: 10.3969/j.issn.1000-8365.2005.04.016 [8] Wang F, Arai S, Endo M. Metallization of multi-walled carbon nanotubes with copper by an electroless deposition process. Electrochem Commun, 2004, 6(10): 1042. doi: 10.1016/j.elecom.2004.08.007 [9] Ding Z P, Zhang X B, Xu G L, et al. Fabrication and tribological properties of carbon nanotubes-aluminum composites. J Zhejiang Univ Eng Sci, 2005, 39(11): 1811 doi: 10.3785/j.issn.1008-973X.2005.11.034丁志鹏, 张孝彬, 许国良, 等. 碳纳米管/铝基复合材料的制备及摩擦性能研究. 浙江大学学报(工学版), 2005, 39(11): 1811 doi: 10.3785/j.issn.1008-973X.2005.11.034 [10] Wang C J. Test research on tribological properties and bonding strength of metal matrix composites. China Plast, 2010, 24(6): 62 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGSU201006023.htm王成军. 金属基复合材料的摩擦学性能及结合强度试验研究. 中国塑料, 2010, 24(6): 62 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGSU201006023.htm -

下载:

下载: