Microstructure and mechanical properties of ceramic particle-reinforced powder metallurgy Fe-2Cu-0.6C composites

-

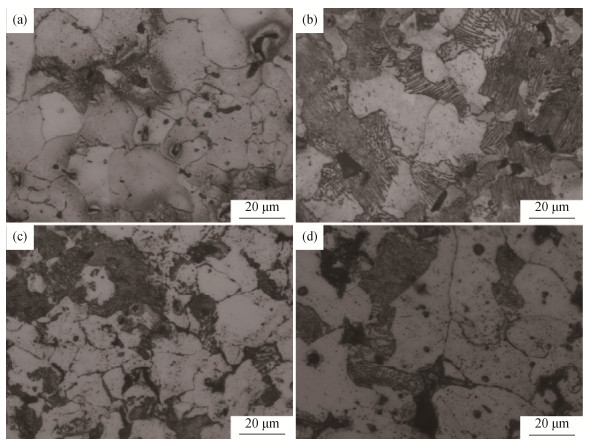

摘要: 采用传统粉末冶金压制/烧结技术,经600 MPa压制、1140℃烧结制备了陶瓷颗粒增强(SiC、TiC及TiB2陶瓷颗粒,质量分数0~1.6%)Fe-2Cu-0.6C低合金钢复合材料,对三种复合材料的微观结构和力学性能进行了研究。结果表明:在烧结过程中,SiC与TiB2颗粒与基体发生反应,故而与基体界面结合良好;当添加质量分数为1.6%的SiC颗粒时,复合材料烧结后的布氏硬度与抗拉强度分别比基体提高了35.9%、69.4%;添加质量分数为1.2%的TiB2颗粒时,复合材料相对密度比基体提高了5.3%,其烧结硬度、抗拉强度与基体相比分别提高了77.9%、72.6%;由于烧结过程中TiC颗粒不与基体发生反应,故而添加TiC颗粒对复合材料的布氏硬度、抗拉强度影响不大。Abstract: Ceramic particle-reinforced Fe-2Cu-0.6C low-alloy steel composites (SiC, TiC, and TiB2 ceramic particles in the mass fraction of 0~1.6%) were prepared by the conventional powder pressing/sintering technology at 600 MPa and 1140℃, the microstructures and mechanical properties of composites were investigated. The results show a good interface bonding between the reinforced particles (SiC and TiB2) and the matrix because of the reaction during sintering. The Brinell hardness and tensile strength of the sintered composites added with 1.6% SiC particles by mass increase by 35.9% and 69.4%, respectively, compared with those of Fe-2Cu-0.6C matrix. When 1.2% TiB2 particles by mass are introduced, the hardness and tensile strength of the sintered composites increase by 77.9% and 72.6%, respectively, compared with those of the matrix. Meanwhile, it is noted that the relative density of the TiB2-reinforced low-alloy steel composite also increases by 5.3%. The addition of TiC particles has little effect on the Brinell hardness and tensile strength of the composites due to no reaction between TiC particles and the matrix.

-

Key words:

- particle reinforcement /

- powder metallurgy /

- iron-based composites /

- mechanical property

-

表 1 FHY100.27还原铁粉化学成分(质量分数)

Table 1. Chemical composition of FHY100.27 reduced iron powder

% C Si Mn P S 氢损(HL) 全铁含量(TFe) 0.010 0.100 0.330 0.012 0.011 0.180 98.570 表 2 陶瓷颗粒增强复合材料体系组成(质量分数)

Table 2. Composition of ceramic particle-reinforced composite system

% 铜粉 石墨 陶瓷颗粒(SiC、TiC、TiB2) 铁粉 2.0 0.6 0.4、0.8、1.2、1.6 余量 -

[1] Efe G C, Ipek M, Zeytin S, et al. An investigation of the effect of SiC particle size on Cu-SiC composites. Composites Part B, 2012, 43(4): 1813 doi: 10.1016/j.compositesb.2012.01.006 [2] Morris D G, Muñoz-Morris M A. Nanoprecipitation of oxide particles and related high strength in oxide-dispersion-strengthened iron-aluminium-chromium intermetallics. Acta Mater, 2013, 61(12): 4636 doi: 10.1016/j.actamat.2013.04.034 [3] Cha L M, Lartigue-Korinek S, Walls M, et al. Interface structure and chemistry in a novel steel-based composite Fe-TiB2 obtained by eutectic solidification. Acta Mater, 2012, 60(18): 6382 doi: 10.1016/j.actamat.2012.08.017 [4] Wang H Y, Jiang Q C, Ma B X, et al. Reactive infiltration synthesis of TiB2-TiC particulates reinforced steel matrix composites. J Alloys Compd, 2005, 391(1-2): 55 doi: 10.1016/j.jallcom.2004.08.045 [5] Bastwros M, Kim G Y. Ultrasonic spray deposition of SiC nanoparticles for laminate metal composite fabrication. Powder Technol, 2016, 288: 279 doi: 10.1016/j.powtec.2015.10.039 [6] Yi D Q, Yu P C, Hu B, et al. Preparation of nickel-coated titanium carbide particulates and their use in the production of reinforced iron matrix composites. Mater Des, 2013, 52: 572 doi: 10.1016/j.matdes.2013.05.097 [7] Sulima I, Boczkal S, Jaworska L. SEM and TEM characterization of microstructure of stainless steel composites reinforced with TiB2. Mater Charact, 2016, 118: 560 doi: 10.1016/j.matchar.2016.07.005 [8] Huang X Q, Zuo A W, Wang Z, et al. Performance of iron-based composites reinforced by different SiC contents. Mater Sci Eng Powder Metall, 2014, 19(2): 271 doi: 10.3969/j.issn.1673-0224.2014.02.018黄小琴, 左爱文, 王哲, 等. SiC含量对铁基复合材料性能的影响. 粉末冶金材料科学与工程, 2014, 19(2): 271 doi: 10.3969/j.issn.1673-0224.2014.02.018 [9] Song B, Dong S J, Coddet P, et al. Microstructure and tensile behavior of hybrid nano-micro SiC reinforced iron matrix composites produced by selective laser melting. J Alloys Compd, 2013, 579(10): 415 http://www.sciencedirect.com/science/article/pii/S0925838813014850 [10] Pelleg J. Reactions in the matrix and interface of the Fe-SiC metal matrix composite system. Mater Sci Eng A, 1999, 269(1-2): 225 doi: 10.1016/S0921-5093(99)00158-6 [11] Lartigue-Korinek S, Walls M, Haneche N, et al. Interfaces and defects in a successfully hot-rolled steel-based composite Fe-TiB2. Acta Mater, 2015, 98: 297 doi: 10.1016/j.actamat.2015.07.024 [12] Efe G C, Zeytin S, Bindal C. The effect of SiC particle size on the properties of Cu-SiC composites. Mater Des, 2012, 36: 633 doi: 10.1016/j.matdes.2011.11.019 [13] Zhang Y F, Ji Z, Liu G M, et al. Manufacturing process and properties of Al2O3 dispersion strengthened copper-based composite with high electrical conductivity. Powder Metall Technol, 2016, 34(5): 346 doi: 10.3969/j.issn.1001-3784.2016.05.005张一帆, 纪箴, 刘贵民, 等. Al2O3弥散增强Cu基高导电率复合材料的制备及性能研究. 粉末冶金技术, 2016, 34(5): 346 doi: 10.3969/j.issn.1001-3784.2016.05.005 [14] Li J R. Ceramic-Metal Composite Material. Beijing: Metallurgical Industry Press, 2004李荣久. 陶瓷-金属复合材料. 北京: 冶金工业出版社, 2004 [15] Liu J W, Lv J, Wang J M, et al. Study on tribological properties of sintered ferrous alloys reinforced by SiC particles. Trans Mater Heat Treat, 2006, 27(1): 16 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL200601005.htm刘君武, 吕珺, 王建民, 等. 微量SiC颗粒增强铁基合金的摩擦磨损性能研究. 材料热处理学报, 2006, 27(1): 16 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL200601005.htm [16] Beygi H, Sajjadi S A, Zebarjad S M. Microstructural analysis and mechanical characterization of aluminum matrix nanocomposites reinforced with uncoated and Cu-coated alumina particles. Mater Sci Eng A, 2014, 607: 81 doi: 10.1016/j.msea.2014.03.050 -

下载:

下载: