-

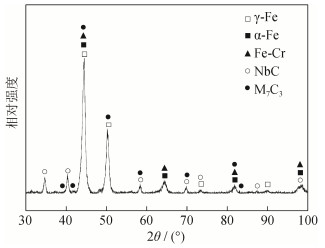

摘要: 采用熔化极气体保护焊技术(gas metal arc welding,GMAW)制备了Fe-Cr-C-Nb堆焊合金,对合金在不同法向载荷(70~190 N)下进行干砂/橡胶轮松散三体磨粒磨损实验。通过X射线衍射分析、扫描电子显微镜观察、能谱分析、磨损失重测试、体视显微镜观察、激光扫描共焦显微镜观察和维氏硬度测量等手段表征了合金显微组织与磨痕特征,研究了合金在不同法向载荷作用下磨损行为的变化。结果表明:堆焊合金显微组织主要由初生奥氏体基体、网状共晶组织及分布于基体上的NbC硬质相组成;合金磨损损失、磨痕深度随法向载荷增大而增大,磨损机制主要为奥氏体基体的微切削及NbC、M7C3的脆性剥落;法向载荷的提高加剧了磨痕亚表面的加工硬化,从而提高了奥氏体基体耐磨性,这导致磨损损失及磨痕深度增长幅度缓慢。Abstract: Fe-Cr-C-Nb hardfacing alloys were prepared by gas metal arc welding (GMAW) method. Loosing abrasive wear tests of dry sand/rubber wheel were carried out on Fe-Cr-C-Nb alloys at different normal loads (70~190 N). Microstructures and wear scar characteristics of alloy were characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM), energy disperse spectroscopy (EDS), weight loss test, stereo microscopy, laser scanning confocal microscopy (LSCM), and Vickers-hardness test to investigate the abrasive wear behavior of alloy in various normal loads. The results show that, the microstructures of Fe-Cr-C-Nb hardfacing alloys are mainly composed of primary austenite matrix, reticular eutectic structure, and NbC hard phase distributed on the matrix. The wear loss and wear scar depth increase with the increase of normal load. The wear mechanism is mainly composed of the micro-cutting of austenite matrix and the brittle flaking of NbC and M7C3. The increase of normal load aggravates the machining hardening of wear scar subsurface, thus improving the wear resistance of austenite matrix and leading to the slow increase of wear loss and wear scar depth.

-

Key words:

- hardfacing alloy /

- hard phase /

- abrasive wear /

- work hardening

-

表 1 堆焊合金化学成分(质量分数)

Table 1. Chemical composition of hard facing alloy

% C Cr Nb Mn Si Ni P、S Fe 1.0~2.5 ≤5.0 ≤15.0 ≤2.5 ≤2.0 0.3~0.5 ≤0.035 余量 表 2 磨损实验相关参数

Table 2. Related parameters of abrasive wear test

磨粒介质 磨粒粒径/μm 橡胶轮表面材料 橡胶轮表面材料硬度 磨粒流速/(g·min-1) 磨损时间/min 橡胶轮线速度/(m·s-1) 法向载荷(变量)/N 铸造石英砂 460~540 氯丁橡胶 A 60 276~288 12.5 3.15 70、100、130、160、190 -

[1] Yang B X. Study on Open-Arc Self-Shield Hardfacing Flux-Cored Wire of Coal Grinding Roller [Dissertation]. Xiangtan: Xiangtan University, 2015杨博翔. 磨煤辊耐磨堆焊明弧自保护药芯焊丝的研究[学位论文]. 湘潭: 湘潭大学, 2015 [2] Lu J, Li Y, Ouyang H, et al. Application and development of surfacing compound technology in China. World Nonferrous Met, 2018(10): 195 doi: 10.3969/j.issn.1002-5065.2018.10.111卢静, 李勇, 欧阳航, 等. 我国堆焊复合技术的应用与发展. 世界有色金属, 2018(10): 195 doi: 10.3969/j.issn.1002-5065.2018.10.111 [3] Tian L, Liu Z Y, Luo Y, et al. Status and development prospects of hardfacing technology for remanufacturing. Electr Weld Mach, 2015, 45(2): 11 https://www.cnki.com.cn/Article/CJFDTOTAL-DHJI201502003.htm田亮, 刘振英, 罗宇, 等. 面向再制造的硬面堆焊技术研究现状和展望. 电焊机, 2015, 45(2): 11 https://www.cnki.com.cn/Article/CJFDTOTAL-DHJI201502003.htm [4] Wang W J, Lewis R, Yang B, et al. Wear and damage transitions of wheel and rail materials under various contact conditions. Wear, 2016, 362-363: 146 doi: 10.1016/j.wear.2016.05.021 [5] Yang J, Tian J J, Hao F F, et al. Microstructure and wear resistance of the hypereutectic Fe-Cr-C alloy hardfacing metals with different La2O3 additives. Appl Surf Sci, 2014, 289: 437 doi: 10.1016/j.apsusc.2013.10.186 [6] Wang J B, Yang J, Wang C X, et al. First-principles calculation on LaAlO3 as the heterogeneous nucleus of TiC. Comput Mater Sci, 2015, 101: 108 doi: 10.1016/j.commatsci.2015.01.024 [7] Yun X, Zhou Y F, Zhao B, et al. Influence of nano-Y2O3 on wear resistance of hypereutectic Fe-Cr-C hardfacing coating. Tribol Lett, 2015, 58: 23 doi: 10.1007/s11249-015-0475-8 [8] Gong J X, Xu J Q, Lu D B, et al. Effects of TiC particles on microstructure and abrasion resistance of Fe-Cr-C-Si alloy hardfacing layers. Mater Mech Eng, 2015, 39(4): 43 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201504010.htm龚建勋, 许继青, 路德斌, 等. TiC颗粒对铁-碳-铬-硅合金堆焊层显微组织及耐磨性的影响. 机械工程材料, 2015, 39(4): 43 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201504010.htm [9] Wu H J, Gong J X, Liu J Q, et al. Effects of WC content on the microstructure and abrasion wear of open arc hardfacing austenitic alloy. Mater Sci Eng Powder Metall, 2016, 21(4): 562 doi: 10.3969/j.issn.1673-0224.2016.04.008吴慧剑, 龚建勋, 刘江晴, 等. WC含量对明弧堆焊奥氏体合金显微组织及耐磨性的影响. 粉末冶金材料科学与工程, 2016, 21(4): 562 doi: 10.3969/j.issn.1673-0224.2016.04.008 [10] Gur A K, Ozay C, Orhan A, et al. Wear properties of Fe-Cr-C and B4C powder coating on AISI 316 stainless steel analyzed by the Taguchi method. Mater Test, 2014, 56(5): 393 doi: 10.3139/120.110578 [11] Tozetti K D, Albertin E, Scandian C. Abrasive size and load effects on the wear of a 19.9% chromium and 2.9% carbon cast iron. Wear, 2017, 376-377: 46 doi: 10.1016/j.wear.2017.02.008 [12] Petrica M, Katsich C, Badisch E, et al. Study of abrasive wear phenomena in dry and slurry 3-body conditions. Tribol Int, 2013, 64(3): 196 http://www.sciencedirect.com/science/article/pii/S0301679X13001758 [13] Wang D F, Zhang B P, Jiang C C, et al. Abrasive wear behaviour of bimodal WC-CoCr coatings sprayed by high velocity oxy-fuel. Powder Metall Technol, 2017, 35(2): 118 doi: 10.3969/j.issn.1001-3784.2017.02.008王大峰, 张波萍, 贾成厂, 等. 超音速火焰喷涂技术制备的双峰WC-CoCr涂层磨粒磨损特性. 粉末冶金技术, 2017, 35(2): 118 doi: 10.3969/j.issn.1001-3784.2017.02.008 [14] Cui Z Q, Qin Y C. Metallography and Heat Treatment. 2nd Ed. Beijing: China Machine Press, 2011崔忠圻, 覃耀春. 金属学与热处理. 2版. 北京: 机械工业出版社, 2011 [15] Song J G, Du D M, Wang F, et al. Effect of forming conditions on the properties of quartz sands porours materials. Powder Metall Technol, 2015, 33(1): 39 http://pmt.ustb.edu.cn/article/id/fmyjjs201501008宋杰光, 杜大明, 王芳, 等. 干压成型工艺对石英基多孔材料的性能影响研究. 粉末冶金技术, 2015, 33(1): 39 http://pmt.ustb.edu.cn/article/id/fmyjjs201501008 [16] Sadeghi F, Najafi H, Abbasi A. The effect of Ta substitution for Nb on the microstructure and wear resistance of an Fe-Cr-C hardfacing alloy. Surf Coat Technol, 2017, 324: 85 doi: 10.1016/j.surfcoat.2017.05.067 [17] Maroli B, Dizdar S. Effects of type and amount of tungsten carbides on the abrasive wear of laser cladded nickel based coatings. Translated by Zhu H B. Therm Spray Technol, 2017, 9(1): 50Maroli B, Dizdar S. WC颗粒类型和数量对激光熔敷镍基涂层磨粒磨损性能的影响. 祝弘滨, 译. 热喷涂技术, 2017, 9(1): 50 [18] Correa E O, Alcântara N G, Valeriano L C, et al. The effect of microstructure on abrasive wear of a Fe-Cr-C-Nb hardfacing alloy deposited by the open arc welding process. Surf Coat Technol, 2015, 276: 479 doi: 10.1016/j.surfcoat.2015.06.026 [19] Yang J, Huang J H, Fan D Y, et al. Microstructure and wear properties of Fe-6wt. %Cr-0.55wt. %C-Xwt. %Nb laser cladding coating and the mechanism analysis. Mater Des, 2015, 88: 1031 doi: 10.1016/j.matdes.2015.09.108 [20] Sabet H, Khierandish S, Mirdamadi S, et al. The microstructure and abrasive wear resistance of Fe-Cr-C hardfacing alloys with the composition of hypoeutectic, eutectic, and hypereutectic at Cr/C=6. Tribol Lett, 2011, 44(2): 237 doi: 10.1007/s11249-011-9842-2 [21] Chotĕborský R, Hrabě P, Müller M, et al. Abrasive wear of high chromium Fe-Cr-C hardfacing alloys. Res Agric Eng, 2008, 54(4): 192 doi: 10.17221/1/2008-RAE [22] Buchanan V E, Mccartney D G, Shipway P H. A comparison of the abrasive wear behaviour of iron-chromium based hardfaced coatings deposited by SMAW and electric arc spraying. Wear, 2008, 264(7-8): 542 doi: 10.1016/j.wear.2007.04.008 [23] Park M C, Shin G S, Yun J Y, et al. Damage mechanism of cavitation erosion in austenite-martensite phase transformable Fe-Cr-C-Mn/Ni alloys. Wear, 2014, 310(1-2): 27 doi: 10.1016/j.wear.2013.12.015 [24] Yun J Y, Shin G S, Park M C, et al. Effect of strain-induced ε and α′-martensitic transformation on cavitation erosion resistance in austenitic Fe-Cr-C-MnFe-Cr-C-Mnti alloys. Wear, 2015, 338-339(2): 379 [25] Correa E O, Alcântara N G, Tecco D G, et al. The relationship between the microstructure and abrasive resistance of a hardfacing alloy in the Fe-Cr-C-Nb-V system. Metall Mater Trans A, 2007, 38(8): 1671 doi: 10.1007/s11661-007-9220-8 -

下载:

下载: