Preparation of FeCuNiSnCo powder by mechanical alloying and the research on physical properties of its matrix material

-

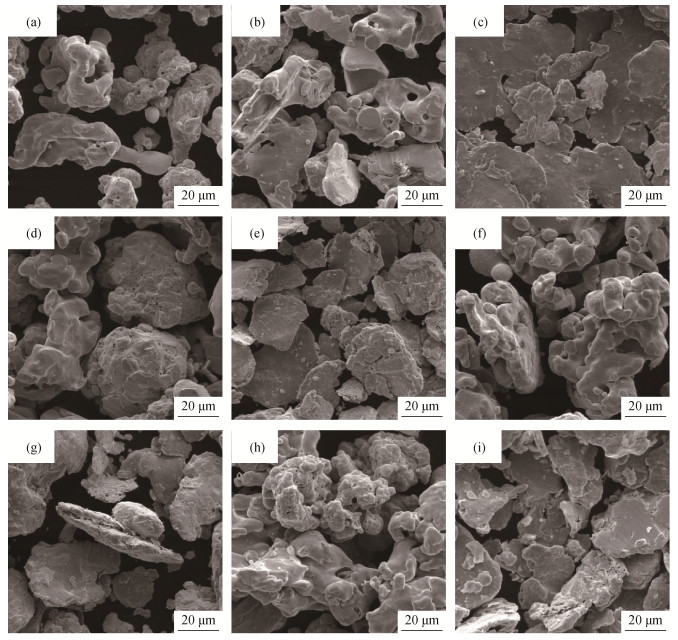

摘要: 采用机械合金化法制备了Fe基预合金粉(FeCuNiSnCo粉末),通过热压烧结制备胎体材料,对制备的Fe基预合金粉末及其胎体性能进行表征,利用正交实验研究了球料比、球磨转速、液固比、球磨时间等对粉末松装密度和胎体材料硬度、抗弯强度的影响,确定最优工艺,并对胎体材料显微组织进行观察。结果表明:在球磨过程中,粉末颗粒经过重组、变形、破碎和合金化,粉末形貌发生了改变,影响了粉末松装密度;球磨转速和球料比是影响胎体材料硬度和强度的主要因素;综合分析最佳工艺参数为:球磨时间6 h,球磨转速400 r·min-1,球料比4:1,液固比0.5:1.0。Abstract: Fe-based pre-alloyed powders (FeCuNiSnCo powders) were prepared by mechanical alloying and the matrix material was prepared by hot-pressing sintering. The mechanical properties and microstructures of pre-alloyed powders and the matrix were characterized to determine the optimal process. The effects of ball-to-powder mass ratio, ball-milling speed, liquid-solid ratio, and ball-milling time on the apparent density of pre-alloyed powders and the hardness and bending strength of the matrix were studied by orthogonal experiment. The results show that, the recombination, deformation, crushing, and alloying of powders occur during the milling process, changing the morphology and density of the powders. The ball-milling speed and ball-to-powder mass ratio are the main factors affecting the hardness and strength of the matrix. The optimum parameters of mechanical alloying are obtained as the ball-milling time is 6 h, the ball-milling speed is 400 r·min-1, the ball-to-powder mass ratio is 4:1, and the liquid-solid ratio is 0.5:1.0.

-

Key words:

- mechanical alloying /

- orthogonal experiment /

- pre-alloyed powders /

- matrix /

- physical properties

-

表 1 Fe基胎体材料化学成分(质量分数)

Table 1. Chemical composition of the matrix material

% Fe Cu Ni Sn Co 其他 余量 44 2.4 5 2 < 0.5 表 2 机械合金化实验参数

Table 2. Experimental factors of mechanical alloying

实验编号 球磨时间/h 球料比 液固比 转速/(r∙min-1) L1 3 1:1 0.5:1.0 100 L2 3 4:1 1.0:1.0 200 L3 3 8:1 2.0:1.0 400 L4 6 1:1 2.0:1.0 200 L5 6 4:1 0.5:1.0 400 L6 6 8:1 1.0:1.0 100 L7 12 1:1 1.0:1.0 400 L8 12 4:1 2.0:1.0 100 L9 12 8:1 0.5:1.0 200 表 3 预合金粉的粒度与松装密度

Table 3. Particle size and apparent density of the pre-alloyed powders

实验编号 L1 L2 L3 L4 L5 L6 L7 L8 L9 粒度(D50)/μm 38.02 41.56 72.78 42.89 33.05 46.56 37 45.26 38.71 松装密度/(g·cm-3) 3.32 3.49 2.18 3.79 3.44 3.53 3.85 3.48 2.75 表 4 预合金粉末松装密度的极差分析

Table 4. Range analysis of the apparent density

因素 K1 K2 K3 R 球磨时间 3.00 3.59 3.36 0.59 球料比 3.65 3.47 2.82 0.83 液固比 3.17 3.62 3.15 0.47 转速 3.44 3.34 3.16 0.29 表 5 胎体材料硬度与抗弯强度表

Table 5. Hardness and bending strength of the matrix materials

实验编号 L1 L2 L3 L4 L5 L6 L7 L8 L9 硬度, HRB 75.1 82.0 92.2 78.4 88.3 78.7 85.7 77.5 91.6 抗弯强度/MPa 926.7 1067.0 1295.5 991.8 1199.5 967.5 1084.7 1003.0 1225.8 表 6 胎体硬度与抗弯强度极差分析表

Table 6. Range analysis of the hardness and bending strength of the matrix materials

因素 K1 K2 K3 R 硬度, HRB 球磨时间 83.10 81.80 84.93 3.13 球料比 79.73 82.60 87.50 7.77 液固比 85.00 82.13 82.70 2.87 转速 77.10 84.00 88.73 11.63 抗弯强度/MPa 球磨时间 1096.40 1052.93 1104.50 51.57 球料比 1001.07 1089.83 1162.93 1162.93 液固比 1117.33 1039.73 1096.77 77.60 转速 965.73 1094.87 1193.23 227.50 -

[1] Zhou H J. Research on Sintering Technology of Metal Bonded Diamond Tools [Dissertation]. Xi'an: Xi'an University of Architecture and Technology, 2014周浩钧. 金属结合剂金刚石工具烧结技术的研究[学位论文]. 西安: 西安建筑科技大学, 2014 [2] Song Z F. Preparation of diamond abrasives for coarse and medium grinding of granite. Stone, 2001(9): 22 doi: 10.3969/j.issn.1005-3352.2001.09.010宋正发. 用于花岗石粗、中磨的金刚石磨具的研制. 石材, 2001(9): 22 doi: 10.3969/j.issn.1005-3352.2001.09.010 [3] Szwed M Z, Konstanty J, Ratuszek W. Study on properties of Fe-Cu powder matrix material for impregnated diamond tools. Transl by Wan X L. Ind Diamond, 2009(2): 15Szwed M Z, Konstanty J, Ratuszek W. 孕镶金刚石工具用Fe-Cu粉末胎体材料的性能研究. 万新梁译. 工业金刚石, 2009(2): 15 [4] Wang G X, Yang K H, Duan L C, et al. Experimental study on new matrix formula of impregnated diamond cutter head. Diamond Abras Eng, 1998(1): 10) https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM199801002.htm汪国香, 杨凯华, 段隆臣, 等. 孕镶金刚石刀头的新型胎体配方试验研究. 金刚石与磨料磨具工程, 1998(1): 10 https://www.cnki.com.cn/Article/CJFDTOTAL-JGSM199801002.htm [5] Guo X G, Liu T, Zhai C H, et al. Study on the mechanism of diamond graphite with the action of transition metals. J Mech Eng, 2016, 52(20): 23 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201620004.htm郭晓光, 刘涛, 翟昌恒, 等. 过渡金属作用下的金刚石石墨化机理研究. 机械工程学报, 2016, 52(20): 23 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201620004.htm [6] Guo X G, Zhai C H, Jin Z J, et al. The study of diamond graphitization under the action of iron-based catalyst. J Mech Eng, 2015, 51(17): 162 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201517021.htm郭晓光, 翟昌恒, 金洙吉, 等. 铁基作用下的金刚石石墨化研究. 机械工程学报, 2015, 51(17): 162 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201517021.htm [7] Tillmann W. Trends and market perspective for diamond tools in the construction industry. Int J Refract Met Hard Mater, 2000, 18(6): 301 doi: 10.1016/S0263-4368(00)00034-2 [8] Zhang S H, Ding X Y, Yang X, et al. Preparation of pre-alloyed powder and it's application in diamond tools. Diamond Abras Eng, 2006, 156(6): 22 doi: 10.3969/j.issn.1006-852X.2006.06.007张绍和, 丁星妤, 杨仙, 等. 金刚石工具胎体预合金粉末制取与应用. 金刚石与磨料磨具工程, 2006, 156(6): 22 doi: 10.3969/j.issn.1006-852X.2006.06.007 [9] Lv S F, Li J, Xia J X. The application of pre-alloyed powder in diamond and tools. Diamond Abras Eng, 2006, 154(4): 81 doi: 10.3969/j.issn.1006-852X.2006.04.023吕申峰, 李季, 夏举学. 国内外预合金粉末在金刚石工具中的应用. 金刚石与磨料磨具工程, 2006, 154(4): 81 doi: 10.3969/j.issn.1006-852X.2006.04.023 [10] Suryanarayana C. Mechanical alloying and milling. Prog Mater Sci, 2001, 46(1-2): 1 doi: 10.1016/S0079-6425(99)00010-9 [11] Li X Q, Li S P, Ding Y L, et al. Effect of high energy milling on the microstructure and mechanical properties of Mg-Zn-Zr alloy. Mater Rev, 2017, 31(9): 77 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201718017.htm李小强, 李尚鹏, 丁艳林, 等. 高能球磨对Mg-Zn-Zr合金微观组织与力学性能的影响. 材料导报, 2017, 31(9): 77 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201718017.htm [12] Yu P L, Yin F X, Wu Z F. Effect of apparent density of powder and shape of the particle on preparation and properties of sintered stainless steel porous material. Powder Metall Technol, 2012, 30(3): 177 doi: 10.3969/j.issn.1001-3784.2012.03.004余培良, 尹凤霞, 吴振芳. 粉末形状与松装密度对不锈钢烧结多孔材料制备工艺及其性能的影响. 粉末冶金技术, 2012, 30(3): 177 doi: 10.3969/j.issn.1001-3784.2012.03.004 [13] Zhang J H, Xiao Z Y, Wen L P, et al. Surface morphology and technical performances of warm compaction powder made by various methods. Mater Sci Eng Powder Metall, 2006, 11(3): 155 doi: 10.3969/j.issn.1673-0224.2006.03.006张菊红, 肖志瑜, 温利平, 等. 不同方法制备的温压粉末形貌及工艺性能. 粉末冶金材料科学与工程, 2006, 11(3): 155 doi: 10.3969/j.issn.1673-0224.2006.03.006 [14] Zhang L, Lv Y Z, Shao J, et al. Study on high velocity compaction and sintering behaviour of bonding treated ferrous powder. Powder Metall Technol, 2012, 30(1): 57 doi: 10.3969/j.issn.1001-3784.2012.01.011章林, 吕元之, 邵健, 等. 粘结化铁基粉末的高速压制成形与烧结行为研究. 粉末冶金技术, 2012, 30(1): 57 doi: 10.3969/j.issn.1001-3784.2012.01.011 [15] Koch C C. Synthesis of nanostructured materials by mechanical milling: problems and opportunities. Nanostruct Mater, 1997, 9(1-8): 13 doi: 10.1016/S0965-9773(97)00014-7 -

下载:

下载: