-

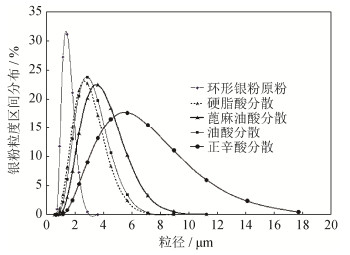

摘要: 以热分解碳酸银得到的类球形银粉作为前驱体,使用硬脂酸、油酸、蓖麻油酸及正辛酸作为分散剂,采用机械球磨法制备片状银粉。通过扫描电镜(scanning electron microscope,SEM)、粒度分布统计(particle size distribution,PSD)、松装密度仪、振实密度仪、四探针仪等手段测试了片状银粉的显微形貌、粒度分布、松装密度、振实密度及导电性。结果表明,分散剂分子中碳链的长度影响片状银粉物理性能,使用油酸作为分散剂可以得到粒径分布窄、松装密度为1.0 g·cm-3、振实密度为1.7 g·cm-3的片状银粉,调制含质量分数50% Ag的低温固化银浆,其方阻小于10 mΩ·□-1。Abstract: Spherical silver powders prepared by the thermal decomposition of silver carbonate were used as the precursors to produce the flake silver powders by mechanical ball milling, adding stearic acid, oleic acid, ricinoleic acid, and caprylic acid as the dispersants. Scanning electron microscope (SEM), particle size distribution (PSD) statistics, apparent density tester, tap density tester, and four point probe instrument were used to study the microstructures, particle size distribution, apparent density, tap density, and conductivity of the flake silver powders. The results show that, the length of carbon chain in dispersant molecules affects the properties of flake silver powders. The flake silver powders in narrower particle size distribution with the apparent density of 1.0 g·cm-3 and the tap density of 1.7 g·cm-3 can be obtained by using oleic acid as the dispersant, and the sheet resistance of silver paste by low temperature curing in the Ag mass fraction of 50% can be below 10 mΩ·□-1.

-

Key words:

- dispersants /

- flake silver powders /

- mechanical ball milling /

- conductivity /

- physical properties

-

表 1 前驱体球形银粉物理性能

Table 1. Physical properties of spherical silver powders as the precursors

材料 松装密度/(g·cm-3) 振实密度/(g·cm-3) 比表面积/(m2·g-1) 粒度/μm D10 D50 D90 AgTD 3.56 5.0 0.36 0.996 1.417 2.029 表 2 分散剂种类和分子结构

Table 2. Species and molecular structures of dispersants

名称 油酸 硬脂酸 蓖麻油酸 正辛酸 分子量 282.47 284.48 298.50 144.21 分子式 C18H34O2 CH3(CH2)16COOH C18H34O3 C8H16O2 表 3 使用不同分散剂磨制片状银粉的物理性能

Table 3. Physical properties of flake silver powders with different dispersants

分散剂 片状银粉的物理性能 振实密度/(g·cm-3) 松装密度/(g·cm-3) 比表面积/(m2·g-1) 酌减/% 硬脂酸 2.42 1.51 1.21 0.70 油酸 1.70 1.00 1.62 0.69 蓖麻油酸 1.77 1.10 1.33 0.70 正辛酸 2.50 1.22 0.85 0.33 -

[1] Sun J, Li Z H. Effect of curing process and morphology of silver powder on resistivity of ECA. Mater Sci Eng Powder Metall, 2009, 14(6): 427 doi: 10.3969/j.issn.1673-0224.2009.06.014孙健, 李芝华. 固化过程及银粉形貌对导电胶电阻率的影响. 粉末冶金材料科学与工程, 2009, 14(6): 427 doi: 10.3969/j.issn.1673-0224.2009.06.014 [2] Gao Y, Yu Y Z. Formation of conductive network upon curing of isotropically conductive adhesives. Adhesion, 2004, 25(6): 1 doi: 10.3969/j.issn.1001-5922.2004.06.001高玉, 余云照. 导电胶固化过程中导电网络形成的机理. 粘接, 2004, 25(6): 1 doi: 10.3969/j.issn.1001-5922.2004.06.001 [3] Liang Y, Li S H, Jin W H, et al. Research progress of conductive adhesives. Precious Met, 2015, 36(1): 75 doi: 10.3969/j.issn.1004-0676.2015.01.020梁云, 李世鸿, 金勿毁, 等. 导电胶的研究进展. 贵金属, 2015, 36(1): 75 doi: 10.3969/j.issn.1004-0676.2015.01.020 [4] Liang H Z, Kim D J, Chung H S, et al. Mechanism for the formation of flake silver powder synthesized by chemical reduction in ethylene glycol. Acta Phys Chim Sin, 2003, 19(2): 150 doi: 10.3866/PKU.WHXB20030212梁焕珍, Kim D J, Chung H S, 等. 乙二醇中化学还原合成片状银粉. 物理化学学报, 2003, 19(2): 150 doi: 10.3866/PKU.WHXB20030212 [5] Liang H Z, Kim D J, Yu K N, et al. Synthesis of hexagonal flake silver powder. Powder Metall Technol, 2003, 21(4): 218 doi: 10.3321/j.issn:1001-3784.2003.04.006梁焕珍, 金东镇, 喻克宁, 等. 六方片状银粉的合成. 粉末冶金技术, 2003, 21(4): 218 doi: 10.3321/j.issn:1001-3784.2003.04.006 [6] Chen S H, Fan Z Y, Carroll D L. Silver nanodisks: synthesis, characterization, and self-assembly. J Phys Chem B, 2002, 106(42): 10777 doi: 10.1021/jp026376b [7] Li X L, Huang F C, Li W L, et al. Research on loose packed flake silver powders with low apparent density. Precious Met, 2012, 33(1): 25 https://www.cnki.com.cn/Article/CJFDTOTAL-GJSZ201201003.htm李晓龙, 黄富春, 李文琳, 等. 低松装密度片状银粉的研究. 贵金属, 2012, 33(1): 25 https://www.cnki.com.cn/Article/CJFDTOTAL-GJSZ201201003.htm [8] Zhong J M, Wang L H, Shi W F, et al. Study of silver powder used for silicon solar cell electronic paste. Powder Metall Ind, 2015, 25(6): 6 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201506002.htm钟景明, 王立惠, 施文峰, 等. 光伏银浆用银粉的研究. 粉末冶金工业, 2015, 25(6): 6 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201506002.htm [9] Ju W, Ma W J, Peng D, et al. Preparation of flake silver powders used for conductive adhesive. Precious Met, 2015, 36(2): 35 https://www.cnki.com.cn/Article/CJFDTOTAL-GJSZ201502006.htm琚伟, 马望京, 彭丹, 等. 导电银胶用片状银粉的制备. 贵金属, 2015, 36(2): 35 https://www.cnki.com.cn/Article/CJFDTOTAL-GJSZ201502006.htm [10] Huang P Y. Theory of Power Metallurgy. 2nd Ed. Beijing: Metallurgical Industry Press, 2004黄培云. 粉末冶金原理. 2版. 北京: 冶金工业出版社, 2004 [11] Shi W F, Ha M, Zhong X, et al. Preparation Method for High-Crystallinity Spherical Silver Powders: China Patent, 102441675B. 2014-06-18施文锋, 哈敏, 钟翔, 等. 高结晶度球形银粉的制备方法: 中国专利, 102441675B. 2014-06-18 [12] Ma Y H. Study on modification of silver chloride resin used for conductive silver paste. China Rubber Plast Technol Equip, 2017, 43(20): 10 https://www.cnki.com.cn/Article/CJFDTOTAL-XJJZ201720002.htm马玉华. 导电银浆用氯醋树脂的改性研究. 橡塑技术与装备, 2017, 43(20): 10 https://www.cnki.com.cn/Article/CJFDTOTAL-XJJZ201720002.htm [13] Tan F B, Zhao L, Liu L, et al. Characteristics and electrical properties of flake-like silver powder and paste. Precious Met, 1999, 20(2): 10 doi: 10.3969/j.issn.1004-0676.1999.02.002谭富彬, 赵玲, 刘林, 等. 片状银粉的特性以及其电性能. 贵金属, 1999, 20(2): 10 doi: 10.3969/j.issn.1004-0676.1999.02.002 [14] Lu D, Wong C P. Characterization of silver flake lubricants. J Therm Anal Calorim, 2000, 59(3): 729 doi: 10.1023/A:1010193402130 [15] Kohinata S, Terao A, Shiraki Y, et al. Relationship between the conductivity of isotropic conductive adhesives (ICAs) and the lubricant coated on silver filler particles. Trans Jpn Inst Electron Packag, 2013, 6(1): 104 doi: 10.5104/jiepeng.6.104 -

下载:

下载: