-

摘要: 制备了含有不同质量分数WC增强颗粒(0%、1%、2%、3%、4%、5%、6%、7%、8%、9%及10%)的Fe-1.5Cu-1.8Ni-0.5Mo-1C粉末冶金复合材料,分析了WC质量分数对复合材料显微组织、硬度与耐磨性能的影响。结果表明,在Fe-1.5Cu-1.8Ni-0.5Mo-1C材料中添加适量的WC颗粒可以提升复合材料的性能,尤其是耐磨性能。当WC颗粒的质量分数在1%~2%时,材料具有较好的组织结构与力学性能,相对于不添加WC增强颗粒的材料,含质量分数1%与2% WC增强颗粒的材料硬度(HRB)分别提升了12.9%和14.3%,磨损量分别降低了50%和52.1%。Abstract: Fe-1.5Cu-1.8Ni-0.5Mo-1C powder metallurgy (P/M) composites added by WC reinforced particles in different mass fraction (0%, 1%, 2%, 3%, 4%, 5%, 6%, 7%, 8%, 9%, 10%) were prepared. The effects of WC content on microstructures, hardness, and wear resistance of composites were analyzed. The results indicate that, WC reinforced particles can improve the mechanical properties of composites, especially the wear resistance. The specimen containing WC reinforced particles in the mass fraction of 1% to 2% show the better microstructures and mechanical properties. Compared with the specimens without WC particles, the hardness of composites containing 1% and 2% WC particles by mass is increased by 12.9% and 12.9%, respectively, and the abrasion loss is reduced by 50% and 52.1%, respectively.

-

Key words:

- WC /

- particle reinforcement /

- wear resistance /

- hardness /

- microstructures

-

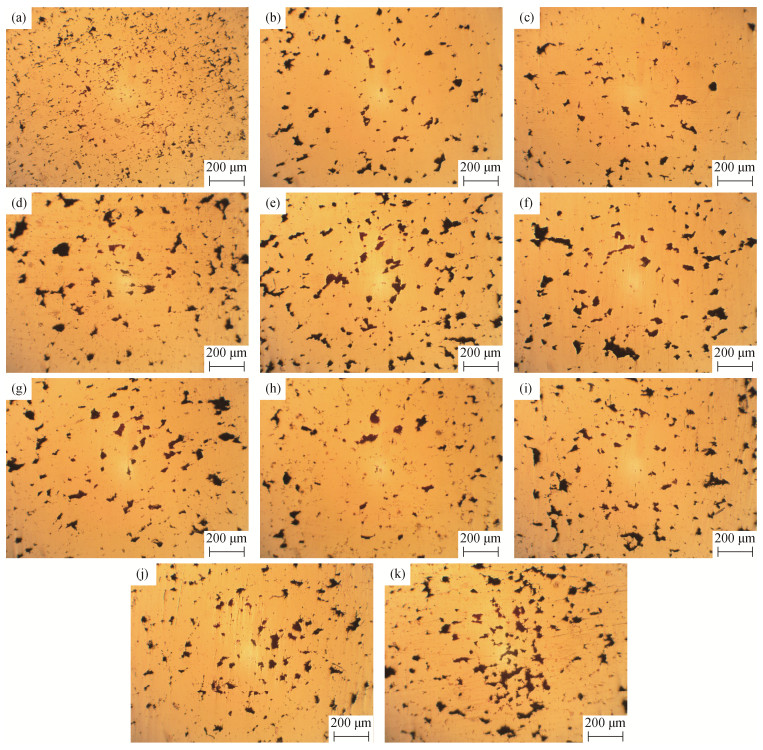

图 1 含不同质量分数WC增强颗粒的Fe-1.5Cu-1.8Ni-0.5Mo-1C复合材料孔隙形貌:(a)0%;(b)1%;(c)2%;(d)3%;(e)4%;(f)5%;(g)6%;(h)7%;(i)8%;(j)9%;(k)10%

Figure 1. Pore morphology of specimens added by WC reinforced particles in different mass fraction: (a) 0%; (b) 1%; (c) 2%; (d) 3%; (e) 4%; (f) 5%;(g) 6%; (h) 7%; (i) 8%; (j) 9%; (k) 10%

表 1 试样成分配比(质量分数)

Table 1. Composition of specimens by mass

% 样品编号 Fe-1.5Cu-1.8Ni-0.5Mo-1C 润滑剂 WC 1# 99.5 0.5 0 2# 98.5 0.5 1 3# 97.5 0.5 2 4# 96.5 0.5 3 5# 95.5 0.5 4 6# 94.5 0.5 5 7# 93.5 0.5 6 8# 92.5 0.5 7 9# 91.5 0.5 8 10# 90.5 0.5 9 11# 89.5 0.5 10 表 2 试样烧结工艺

Table 2. Sintering process of specimens

烧结段 温度/℃ 时间/min 1 865 18 2 975 18 3 1110 18 4 1120 18 5 1115 18 7 冷却段 90 -

[1] Wang K, Zhang L H, Li Z H, et al. Mechanism of ultrasonic field on the particle micro-agglomeration and interfacial bonding of SiCp/7085 composites. Chin J Eng, 2017, 39(2): 238 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201702011.htm王坤, 张立华, 黎正华, 等. 超声外场对SiCp/7085复合材料颗粒微观团聚与界面结合的作用机理. 工程科学学报, 2017, 39(2): 238 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201702011.htm [2] Fan T, Liu B W, Sun Y R, et al. Study on wear resistance of Al2O3 particle reinforced Al matrix composites. Powder Metall Technol, 2015, 33(3): 186 doi: 10.3969/j.issn.1001-3784.2015.03.006范涛, 刘博文, 孙艳荣, 等. Al2O3颗粒增强铝基复合材料的耐磨性研究. 粉末冶金技术, 2015, 33(3): 186 doi: 10.3969/j.issn.1001-3784.2015.03.006 [3] Wu C, Sun A Z, Liu Y S, et al. Preparation and properties of nano-SiC particle reinforced Al-Mg composite. Powder Metall Technol, 2017, 35(3): 182 doi: 10.19591/j.cnki.cn11-1974/tf.2017.03.004吴超, 孙爱芝, 刘永生, 等. 纳米SiC颗粒增强铝镁复合材料的制备与性能研究. 粉末冶金技术, 2017, 35(3): 182 doi: 10.19591/j.cnki.cn11-1974/tf.2017.03.004 [4] Li Y Y, Ni K Y, Zhu F W. Study of TiC particle-reinforced Cu matrix composites. Powder Metall Technol, 2018, 36(2): 106 doi: 10.19591/j.cnki.cn11-1974/tf.2018.02.005李月英, 倪慨宇, 祝夫文. TiC颗粒增强铜基复合材料的研究. 粉末冶金技术, 2018, 36(2): 106 doi: 10.19591/j.cnki.cn11-1974/tf.2018.02.005 [5] Liu X, Ding K W, Liu Y L. Sliding friction and wear properties of WC particles reinforced high chrome steel matrix surface composite. Hot Work Technol, 2015, 44(14): 174 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201514050.htm刘旋, 丁克伟, 刘运林. WC颗粒增强高铬钢基表面复合材料的滑动摩擦磨损性能研究. 热加工工艺, 2015, 44(14): 174 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201514050.htm [6] Yuan Q B, Hu C, Chen X Z. Effect of heat source on Fe-based coating reinforced by in-situ synthesized WC particles. Hot Work Technol, 2016, 45(4): 162 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201604051.htm袁其兵, 胡超, 陈希章. 热源对原位合成WC颗粒增强铁基涂层的影响. 热加工工艺, 2016, 45(4): 162 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201604051.htm [7] Li X Q, Chen H J, Li Z Y, et al. Study on manufacturing and wear resistance of WC reinforced Fe-2Cu-2Ni-1Mo-1C powder metallurgy steel. J Mech Eng, 2013, 49(18): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201318009.htm李小强, 陈火金, 李子阳, 等. WC增强Fe-2Cu-2Ni-1Mo-1C粉末冶金钢的制备及其耐磨性能研究. 机械工程学报, 2013, 49(18): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201318009.htm [8] Li X Q, Lai Y G, Chen J. Microstructure and mechanical properties of WCp reinforced iron-based alloy by mechanical alloying and spark plasma sintering. Mater Sci Eng Powder Metall, 2012, 17(5): 599 doi: 10.3969/j.issn.1673-0224.2012.05.009李小强, 赖燕根, 陈健. 机械合金化与放电等离子烧结制备WC颗粒增强Fe基合金的组织与力学性能. 粉末冶金材料科学与工程, 2012, 17(5): 599 doi: 10.3969/j.issn.1673-0224.2012.05.009 [9] Li X Q, Li Z Y, Ao J P, et al. Preparation of nano-WC particles reinforced high chromium iron-based powder metallurgy materials. Mater Sci Eng Powder Metall, 2014, 19(4): 615 doi: 10.3969/j.issn.1673-0224.2014.04.018李小强, 李子阳, 敖敬培, 等. 纳米WC颗粒增强高铬铁基粉末冶金材料的制备. 粉末冶金材料科学与工程, 2014, 19(4): 615 doi: 10.3969/j.issn.1673-0224.2014.04.018 [10] Cheng X L, Gao Y M, Xing J D, et al. Preparation of warm compacted and sintered WC/45 steel composite and its wear-resistance. J Xi′An Jiaotong Univ, 2005, 39(1): 53 doi: 10.3321/j.issn:0253-987X.2005.01.013成小乐, 高义民, 邢建东, 等. WC/45钢复合材料的温压烧结工艺及其磨损性能. 西安交通大学学报, 2005, 39(1): 53 doi: 10.3321/j.issn:0253-987X.2005.01.013 [11] Arsenault R J, Wang L, Feng C R. Strengthening of composites due to microstructural changes in the matrix. Acta Metall et Mater, 1991, 39(1): 47 doi: 10.1016/0956-7151(91)90327-W [12] Evans A G, Hutchinson J W, Mcmeeking R M. Stress-strain behavior of metal matrix composites with discontinuous reinforcements. Scr Metall Mater, 1991, 25(1): 3 doi: 10.1016/0956-716X(91)90344-Z [13] Arsenault R J, Shi N. Dislocation generation due to differences between the coefficients of thermal expansion. Mater Sci Eng, 1986, 81(1-2): 175 http://www.sciencedirect.com/science/article/pii/0025541686902612 [14] Wu Y, Lavernia E J. Strengthening behavior of particulate reinforced MMCs. Scr Metall Mater, 1992, 27(2): 173 doi: 10.1016/0956-716X(92)90108-Q [15] Starink M J, Wang P, Sinclair I. Microstructure and strengthening of Al-Li-Cu-Mg alloys and MMCs: Ⅱ. Modelling of yield strength. Acta Mater, 1999, 47(14): 3855 doi: 10.1016/S1359-6454(99)00228-1 [16] Zhao M H, Liu A G, Guo M H. Research on WC reinforced metal matrix composite. Weld Joining, 2006(11): 26 doi: 10.3969/j.issn.1001-1382.2006.11.006赵敏海, 刘爱国, 郭面焕. WC颗粒增强耐磨材料的研究现状. 焊接, 2006(11): 26 doi: 10.3969/j.issn.1001-1382.2006.11.006 [17] You X H. Behaviour of hard phase of steel bonded WC hard alloy during heat treatment. Powder Metall Technol 1984(2): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ198402000.htm游兴河. WC系钢结硬质合金热处理中硬质相的行为. 粉末冶金技术, 1984(2): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ198402000.htm -

下载:

下载: