Effects of microwave sintering and conventional sintering on microstructures and properties of pure titanium

-

摘要: 和熔炼铸造法相比,采用粉末冶金法制备钛材,可以避免引入杂质,提高原料利用率。本文探讨微波烧结与传统烧结对纯钛组织及性能的影响,结果表明,在1200℃保温2 h传统烧结得到等轴α-Ti组织,密度为4.33 g·cm-3,相对密度为96.06%,硬度为HV 260,抗压强度为1309 MPa,断面膨胀率为10.63%,呈典型的解理状脆性断裂;在1200℃保温15 min微波烧结得到等轴的α-Ti与条状β-Ti组织,密度为4.30 g·cm-3,相对密度为95.45%,硬度为HV 311,抗压强度为1175 MPa,断面膨胀率为18.89%,展现出一定的塑性,呈准解理状脆性断裂。Abstract: Compared with the smelting and casting method, powder metallurgy method can avoid impurities and improve the utilization rate of materials. The microstructures and properties of pure titanium prepared by microwave sintering and conventional sintering were studied in this paper. The results show that, the equiaxed grain α-Ti microstructure is acquired by conventional sintering at 1200 ℃ for 2 h, the relative density, density, hardness, compressive strength, and fracture expansion rate are 96.06%, 4.33 g·cm-3, HV 260, 1309 MPa, and 10.63%, respectively. The conventional sintering titanium samples display the typical cleavage brittle fracture. Furthermore, the equiaxed grain α-Ti and strip β-Ti microstructure are acquired by microwave sintering at 1200 ℃ for 15 min, the relative density, density, hardness, compressive strength, and fracture expansion rate are 95.45%, 4.30 g·cm-3, HV 311, 1175 MPa, and 18.89%, respectively. The microwave sintering titanium samples display the quasi-cleavage brittle fracture.

-

图 3 1200 ℃传统烧结与微波烧结纯钛试样金相组织:(a)传统烧结腐蚀前;(b)微波烧结腐蚀前;(c)传统烧结腐蚀后;(d)微波烧结腐蚀后

Figure 3. Microstructures of pure titanium samples by different sintering technology at 1200 ℃ (a) conventional sintering before corrosion; (b) microwave sintering before corrosion; (c) conventional sintering after corrosion; (d) microwave sintering after corrosion

图 4 传统烧结与微波烧结纯钛试样硬度分布:(a)垂直于压制方向,靠近压头端由中心到周围的硬度分布;(b)沿压制方向,从压头到底面处的硬度分布

Figure 4. Vickers hardness distribution of pure titanium samples by conventional sintering and microwave sintering: (a) perpendicular to the pressing direction from the center to around; (b) along the pressing direction from the pressure head to bottom

图 6 传统烧结与微波烧结纯钛试样断口形貌:(a)传统烧结(×60);(b)传统烧结(×2000);(c)传统烧结(×5000);(d)微波烧结(×40);(e)微波烧结(×2000);(f)微波烧结(×5000)

Figure 6. Fracture morphology of pure titanium samples by different sintering technology: (a) conventional sintering (×60); (b) conventional sintering (×2000); (c) conventional sintering (×5000); (d) microwave sintering (×40); (e) microwave sintering (×2000); (f) microwave sintering (×5000)

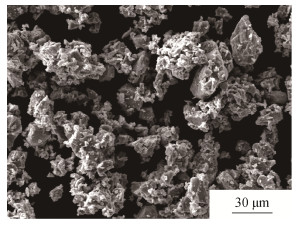

表 1 纯Ti粉化学成分(质量分数)

Table 1. Chemical composition of pure Ti powders

% Fe Si Mg Mn O C N H Ti 其他 0.06 0.02 0.02 0.02 0.30 0.02 0.05 0.04 余量 0.05 表 2 不同烧结方式制备纯钛的相对密度

Table 2. Relative density of pure titanium samples by different sintering technology

试样编号 相对密度/% 密度/(g·cm-3) 生坯 75.00 3.3825 微波烧结(1200 ℃,15 min) 95.45 4.3048 传统烧结(1200 ℃,2 h) 96.06 4.3323 -

[1] Zhao Y, Zhang D F, Jiang Y. Preparation of SP-700 alloy using powder metallurgy. Mater Sci Eng Powder Metall, 2008, 13(5): 284 doi: 10.3969/j.issn.1673-0224.2008.05.006赵瑶, 张端锋, 江垚. 粉末冶金钛合金SP-700的制备. 粉末冶金材料科学与工程, 2008, 13(5): 284 doi: 10.3969/j.issn.1673-0224.2008.05.006 [2] Cai Y X, Li D R. Application of Ti-alloy prepared by powder metallurgy. Mater China, 2010, 29(5): 30 https://www.cnki.com.cn/Article/CJFDTOTAL-XJKB201005008.htm蔡一湘, 李达人. 粉末冶金钛合金的应用现状. 中国材料进展, 2010, 29(5): 30 https://www.cnki.com.cn/Article/CJFDTOTAL-XJKB201005008.htm [3] Xiao D H, Yuan T C, He Y H, et al. Synthesis and mechanical properties of powder metallurgical titanium alloy. Chin J Nonferrous Met, 2010, 20(Suppl 1): 303 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ2010S1069.htm肖代红, 袁铁锤, 贺跃辉, 等. 粉末冶金钛合金的制备与力学性能. 中国有色金属学报, 2010, 20(增刊1): 303 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ2010S1069.htm [4] He J, Xiao Z Y, Guan H J, et al. High velocity compaction behavior and sintered properties of pure Ti powder. Powder Metall Technol, 2016, 34(3): 178 doi: 10.3969/j.issn.1001-3784.2016.03.004何杰, 肖志瑜, 关航健, 等. 纯钛粉高速压制行为及其烧结性能研究. 粉末冶金技术, 2016, 34(3): 178 doi: 10.3969/j.issn.1001-3784.2016.03.004 [5] Weng Q G, Li R D, Zhou L B, et al. Densification dynamics and microstructure evolution behavior of spark plasma sintering of titanium powder. Mater Sci Eng Powder Metall, 2015, 20(1): 149 doi: 10.3969/j.issn.1673-0224.2015.01.024翁启钢, 李瑞迪, 周立波, 等. 纯钛粉放电等离子烧结致密化的动力学与组织演变行为. 粉末冶金材料科学与工程, 2015, 20(1): 149 doi: 10.3969/j.issn.1673-0224.2015.01.024 [6] Chen W G, Wang F Z. Powder Metallurgy Technology and Materials. Beijing: Metallurgical Industry Press, 2011.陈文革, 王发展. 粉末冶金工艺及材料. 北京: 冶金工业出版社, 2011 [7] Jin X J, Chang A M, Zhang H M, et al. A comparison study of sinterability and electrical properties for microwave and conventional sintered Mn0.43Ni0.9CuFe0.67O4 ceramics. J Mater Sci Technol, 2010, 26(4): 344 doi: 10.1016/S1005-0302(10)60056-4 [8] Takayama S, Saito Y, Sato M, et al. Sintering behavior of metal powders involving microwave-enhanced chemical reaction. Jpn J Appl Phys Part 1, 2006, 45(3A): 1816 doi: 10.1143/JJAP.45.1816 [9] Bao R, Yi J H. Application of microwave sintering technology in cemented carbide preparation. Chin J Nonferrous Met, 2014, 24(6): 1544 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201406022.htm鲍瑞, 易健宏. 微波烧结技术在硬质合金制备中的应用. 中国有色金属学报, 2014, 24(6): 1544 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201406022.htm [10] Anklekar R M, Bauer K, Agrawal D K, et al. Improved mechanical properties and microstructural development of microwave sintered copper and nickel steel PM parts. Powder Metall, 2005, 48(1): 39 doi: 10.1179/003258905X37657 [11] Bykov Y V, Rybakov K I, Semenov V E. High-temperature microwave processing of materials. J Phys D: Appl Phys, 2001, 34: 55 doi: 10.1088/0022-3727/34/13/201 [12] Luo S D, Qian M, Ashraf Imam M. Microwave sintering of titanium and titanium alloys. Titanium Powder Metallurgy — Science, Technology and Applications, Eds. by Qian M and (Sam) Froes F H. Oxford: Butterworth-Heinemann, 2015 [13] Wu D, Chen W G, Zhou X, et al. Microwave sintering of ferrous metal powders and influence of particle size. Powder Metall Technol, 2015, 33(3): 213 doi: 10.3969/j.issn.1001-3784.2015.03.011吴丹, 陈文革, 周弦, 等. 不同粒度大小粉末的微波烧结试验探讨. 粉末冶金技术, 2015, 33(3): 213 doi: 10.3969/j.issn.1001-3784.2015.03.011 [14] Huang J W, Peng H. A study of microwave sintered Fe-Cu-C PM alloy. Min Metall Eng, 2005, 25(5): 77 https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC200505021.htm黄加伍, 彭虎. 粉末冶金Fe-Cu-C合金的微波烧结研究. 矿冶工程, 2005, 25(5): 77 https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC200505021.htm [15] Zhu F X, Yi J H, Peng Y D. Sintering response of copper powder metal compact in microwave field. J Central South Univ Sci Technol, 2009, 40(1): 106 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD200901020.htm朱凤霞, 易健宏, 彭元东. 微波烧结金属纯铜压坯. 中南大学学报(自然科学版), 2009, 40(1): 106 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD200901020.htm [16] Li K, Yang P. Interaction among deformation, recrystallization and phase transformation of TA2 Pure titanium during hot compression. Trans Nonferrous Met Soc China, 2016, 26(7): 1863 doi: 10.1016/S1003-6326(16)64302-9 [17] Liu Y B. Microstructure Evolution of TA2 Commercial Pure Titanium at High Temperature [Dissertation]. Shanghai: Shanghai Jiao Tong University, 2010刘以波. TA2工业纯钛高温组织演变研究[学位论文]. 上海: 上海交通大学, 2010 [18] Xin S W, Zhao Y Q, Zeng W D. Induction and discussion of solid state phase transformation of titanium alloys (Ⅰ)——allotropic transformation. Titanium Ind Prog, 2007, 24(5): 23 https://www.cnki.com.cn/Article/CJFDTOTAL-TGYJ200705008.htm辛社伟, 赵永庆, 曾卫东. 钛合金固态相变的归纳与讨论(Ⅰ)——同素异构转变. 钛工业进展, 2007, 24(5): 23 https://www.cnki.com.cn/Article/CJFDTOTAL-TGYJ200705008.htm [19] Peng Y D. Studies on Microwave Heating Mechanism and Sintering Behavior of Powder Metallurgy Materials [Dissertation]. Changsha: Central South University, 2011彭元东. 微波加热机制及粉末冶金材料烧结特性研究[学位论文]. 长沙: 中南大学, 2011 [20] Li L. Study on Damage and Fracture Behavior of TiAl Based Alloys under Compression [Dissertation]. Lanzhou: Lanzhou University of Technology, 2008李雷. TiAl基合金在压缩状态下的损伤断裂行为研究[学位论文]. 兰州: 兰州理工大学, 2008 -

下载:

下载: