-

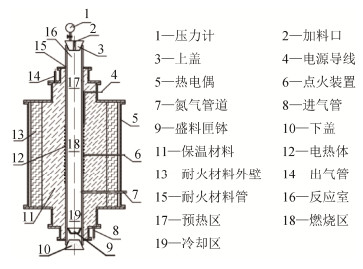

摘要: 氮化硅铁是近年来高温材料领域的新型复相材料,主要由氮化硅和硅铁合金组成。自20世纪70年代以来,氮化硅铁作为高炉用炮泥材料取得了良好的使用效果,但其制备成本过高制约了进一步的发展。20世纪90年代,北京科技大学无机非金属结构材料研究室利用闪速燃烧合成技术实现了氮化硅铁高性价比的大规模产业化制备,大大推动了氮化硅铁材料的研究与应用,在铁钩浇注料等领域取得了良好的使用效果。本文介绍了氮化硅铁的制备、结构及性能,分析了闪速燃烧合成氮化硅铁的工艺原理,总结了氮化硅铁在不同应用环境下的使用性能,以及目前的应用状况,并展望了氮化硅铁材料的研究方向及其潜在的应用领域。Abstract: As a novel multiphase material used in the high temperature material field in recent years, ferrosilicon nitride is mainly composed of silicon nitride and ferrosilicon. Since the 1970s, the ferrosilicon nitride has shown the good performance using as the blast furnace materials, but the excessive preparation cost has greatly restricted its further development. In the 1990s, the industrialized preparation of cost-effective ferrosilicon nitride was realized by flash-combustion synthesis technology developed by the Laboratory of Inorganic Non-Metallic Structural Materials, University of Science and Technology Beijing, which promoted the research and popularization of ferrosilicon nitride materials. In addition to the taphole clay, the ferrosilicon nitride has also shown the good performance used as castables. The preparation, structure, and properties of ferrosilicon nitride were introduced in this paper, the reaction mechanism of flash-combustion synthesis was analyzed, the performance and application of ferrosilicon nitride in different environments were summarized, and the research direction and potential applications of ferrosilicon nitride materials were prospected.

-

表 1 FeSi75氮化硅铁化学成分(质量分数)

Table 1. Chemical composition of FeSi75 ferrosilicon nitride by mass

% Si Fe Mg Ca Al Mn P 77.10 19.30 0.14 1.95 1.19 0.14 0.04 -

[1] Li B. Investigation on Mechanism and Application of Ferrous Silicon Nitride Synthesized by Flashing Combustion [Dissertation]. Beijing: University of Science and Technology Beijing, 2016李斌. 闪速燃烧合成氮化硅铁机理及应用研究[学位论文]. 北京: 北京科技大学, 2016 [2] Iwamoto S. Method for Manufacture of Ferrosilicon Nitride: United States Patent, 4150999. 1979-04-24 [3] Chen S P, Gan F F. Application of gunmud with Si3N4 in taphole of BF. Baosteel Technol, 1995(2): 54 https://www.cnki.com.cn/Article/CJFDTOTAL-BGJS502.012.htm陈守平, 甘芳菲. Si3N4在高炉出铁口炮泥中的应用. 宝钢技术, 1995(2): 54 https://www.cnki.com.cn/Article/CJFDTOTAL-BGJS502.012.htm [4] Zhu S J, Sun J L, Chen J H, et al. Flash combustion synthesis of ferro silicon nitride with ferrosilicon. Refractories, 2004, 38(4): 249 doi: 10.3969/j.issn.1001-1935.2004.04.008祝少军, 孙加林, 陈俊红, 等. 硅铁闪速燃烧合成氮化硅铁. 耐火材料, 2004, 38(4): 249 doi: 10.3969/j.issn.1001-1935.2004.04.008 [5] Sun J L, Hong Y R, Zhu S J. Method and Equipment for Synthesis of Silicon Nitride or Ferrosilicon Nitride by Low-Pressure Combustion: China Patent, ZL02158760.4. 2003-06-18孙加林, 洪彦若, 祝少军. 低压燃烧合成氮化硅或氮化硅铁的方法及设备: 中国专利, ZL02158760.4. 2003-06-18 [6] Chen J H. The Composition and Structure of Fe-Si3N4 and Its Effect on High Temperature Performance of Al2O3-SiC-C Composite Refractories [Dissertation]. Beijing: University of Science and Technology Beijing, 2005陈俊红. Fe-Si3N4的组成、结构及其对Al2O3-SiC-C体系材料高温性能的影响[学位论文]. 北京: 北京科技大学, 2005 [7] Zhu S J. Study on Flash Combustion Synthesis Mechanism of Silicon Nitride [Dissertation]. Beijing: University of Science and Technology Beijing, 2005祝少军. 氮化硅闪速燃烧合成机理研究[学位论文]. 北京: 北京科技大学, 2005 [8] Goto Y, Thomas G. Phase transformation and microstructural changes of Si3N4 during sintering. J Mater Sci, 1995, 30(9): 2194 doi: 10.1007/BF01184561 [9] Chen J H, Sun J L, Xue W D, et al. Research of the microstructure and nitriding capability of ferrosilicon. Ferro-Alloys, 2004, 35(3): 18 doi: 10.3969/j.issn.1001-1943.2004.03.004陈俊红, 孙加林, 薛文东, 等. FeSi75铁合金显微结构与氮化性能的研究. 铁合金, 2004, 35(3): 18 doi: 10.3969/j.issn.1001-1943.2004.03.004 [10] Zhan H S, Xue W D, Chen J H, et al. Basic research on Fe3Si-Si3N4 compound powder synthesized by flashing combustion process. Chin J Rare Met, 2006, 30(Suppl 1): 97 https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS2006S1023.htm占华生, 薛文东, 陈俊红, 等. 闪速燃烧合成Fe3Si-Si3N4复合粉体的基础研究. 稀有金属, 2006, 30(增刊1): 97 https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS2006S1023.htm [11] Li B, Chen J H, Su J D, et al. Morphology of α-Si3N4 in Fe-Si3N4 prepared via flash combustion. Int J Miner Metall Mater, 2015, 22(12): 1322 doi: 10.1007/s12613-015-1200-1 [12] Chen J H, Wang X D, Sun J L, et al. Research on the Fe-silicon nitride material self-producing N2 at high temperature. Int J Miner Metall Mater, 2006, 13(1): 78 http://www.cnki.com.cn/Article/CJFDTotal-BJKY200601016.htm [13] Li B, Chen J H, Jiang P, et al. Reaction behavior of trace oxygen during combustion of falling FeSi75 powder in a nitrogen flow. Int J Miner Metall Mater, 2016, 23(8): 959 doi: 10.1007/s12613-016-1312-2 [14] Li B, Jiang P, Yan M W, et al. Characterization and properties of rapid fabrication of network porous Si3N4 ceramics. J Alloys Compd, 2017, 709: 717 doi: 10.1016/j.jallcom.2017.03.223 [15] Chen J H, Sun J L, Kang H R, et al. Sintering experiment of ferro-silicon nitride in air atmosphere. Refractories, 2005, 39(3): 185 doi: 10.3969/j.issn.1001-1935.2005.03.008陈俊红, 孙加林, 康华荣, 等. 氮化硅铁在空气气氛中的烧结试验. 耐火材料, 2005, 39(3): 185 doi: 10.3969/j.issn.1001-1935.2005.03.008 [16] Li B, Chen J H, Yan M W, et al. Morphology evolution and phase interactions of Fe-containing Si3N4 in vacuum high-temperature environment. ISIJ Int, 2016, 56(2): 189 doi: 10.2355/isijinternational.ISIJINT-2015-487 [17] Liu X G. Study on High Temperature Properties and Application of Ferrous Silicon Nitride Synthesized by Flashing Combustion Process [Dissertation]. Beijing: University of Science and Technology Beijing, 2005刘晓光. 燃速燃烧合成氮化硅铁的性能[学位论文]. 北京: 北京科技大学, 2005 [18] Chen J H, Sun J L, Deng X L, et al. Influence of ferro-Si3N4 on oxidation resistance of Al2O3-SiC-C castable for trough. Refractories, 2005, 39(1): 50 https://www.cnki.com.cn/Article/CJFDTOTAL-LOCL20050100B.htm陈俊红, 孙加林, 邓小玲, 等. 氮化硅铁在Al2O3-SiC-C质铁沟浇注料中的防氧化行为. 耐火材料, 2005, 39(1): 50 https://www.cnki.com.cn/Article/CJFDTOTAL-LOCL20050100B.htm [19] Chen J H, Wang F M, Sun J L, et al. Effect of ferro-Si3N4 on hot bending strength and slag resistance of taphole mix. Refractories, 2006, 40(6): 443 doi: 10.3969/j.issn.1001-1935.2006.06.012陈俊红, 王福明, 孙加林, 等. 氮化硅铁对炮泥高温抗折强度及抗渣性的影响. 耐火材料, 2006, 40(6): 443 doi: 10.3969/j.issn.1001-1935.2006.06.012 [20] Zhan H S, Sun J L, Chen J H, et al. Development of Al2O3-SiC-C gunmud containing ferrosilicon nitride. Refractories, 2005, 39(3): 309 https://www.cnki.com.cn/Article/CJFDTOTAL-LOCL200504021.htm占华生, 孙加林, 陈俊红, 等. 含氮化硅铁的Al2O3-SiC-C炮泥的研制. 耐火材料, 2005, 39(3): 309 https://www.cnki.com.cn/Article/CJFDTOTAL-LOCL200504021.htm [21] Iizuka K, Kometani K, Kaga T. Behavior of ferro-Si3N4 in taphole mud. Refractories, 1996, 48(11): 577 http://ci.nii.ac.jp/naid/10003722967 -

下载:

下载: