Study on microstructures and properties of S136 die steel formed by selective laser melting after heat treatment

-

摘要: 激光选区熔化是非平衡凝固过程,成形过程会产生热应力及组织应力,造成金属零件开裂、变形等缺陷,后期热处理是改善激光选区熔化金属零件微观组织和提升性能的有效手段。本文研究了后期热处理参数(热处理温度、保温时间及冷却方式)对激光选区熔化成形的S136模具钢零件微观组织和性能的影响。结果表明:最优热处理参数为1050℃,保温30 min,水冷。在最优热处理工艺下S136模具钢试样洛氏硬度达到HRC 53.7,比热处理之前提高了8.6%,洛氏硬度标准差比热处理之前降低了37.14%,硬度均匀性得到显著改善;试样的耐磨性、最大显微硬度和最大弹性模量比热处理前分别提升33.5%、3.3%和8.6%;试样的熔池形态鳞状形貌结构消失,碳化物相CrFe7C0.45溶解,组织均匀,基本呈现各向同性特征。Abstract: Selective laser melting (SLM) is a non-equilibrium solidification process and can cause the thermal and structural stress, resulting in the cracking and deformation of metal parts. Post-heat treatment is an important way to improve the microstructures and properties of SLM metal parts. The effects of post-heat treatment parameters on microstructures and properties of S136 die steel formed by SLM were investigated in this paper, including heat treatment temperature, holding time, and cooling mode. In the results, the optimal heat treatment parameters are found as 1050℃, 30 min, and water cooling. Rockwell hardness is found up to HRC 53.7, increasing by 8.6% than that of as-formed sample. The uniformity of hardness is greatly improved as the standard deviation of Rockwell hardness decreased by 37.14%. The wear resistance, maximum micro-hardness, and maximum elastic modulus of heat treated sample are increased by 33.5%, 3.3% and 8.6%, respectively. The scaly structure morphology of molten pool is disappeared, CrFe7C0.45 carbide is dissolved, and the uniform and isotropic microstructures are present.

-

Key words:

- selective laser melting /

- heat treatment /

- hardness /

- wear resistance /

- microstructures

-

图 10 S136模具钢SLM成形件热处理后显微硬度和弹性模量:(a)X轴方向显微硬度;(b)X轴方向弹性模量;(c)Y轴方向显微硬度;(d)Y轴方向弹性模量

Figure 10. Micro-hardness and elastic modulus of S136 die steel by SLM after heat treatment: (a) micro-hardness in X-axis direction; (b) elastic modulus in X-axis direction; (c) micro-hardness in Y-axis direction; (d) elastic modulus in Y-axis direction

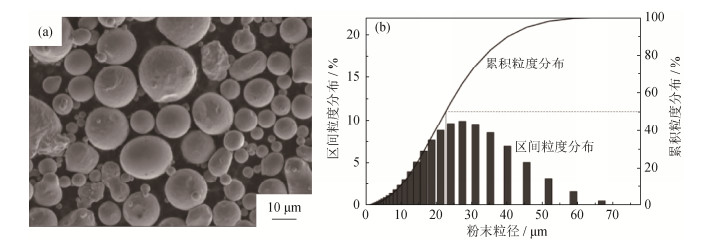

表 1 S136模具钢粉化学成分(质量分数)

Table 1. Chemical composition of S136 die steel powders

% C Cr Mn Si V Fe 0.34 14.64 < 0.81 < 0.55 0.35 余量 表 2 3D打印成形实验参数

Table 2. Experimental parameters of 3D printing forming

扫描功率,P/W 扫描速度,V/(mm·s-1) 扫描间距,S/mm 铺粉厚度,H/mm 140 550 0.08 0.02 表 3 SLM成形S136模具钢试样后续热处理制度

Table 3. Heat treatment process of S136 die steel samples formed by SLM

试样编号 加热温度/℃ 保温时间/min 冷却方式 1# 850 30 水冷,空冷 2# 950 30 水冷,空冷 3# 1050 30 水冷,空冷 4# 1150 30 水冷,空冷 5# 1050 10 水冷,空冷 6# 1050 20 水冷,空冷 7# 1050 40 水冷,空冷 8# 1050 50 水冷,空冷 表 4 显微硬度和弹性模量热处理前后变化幅度

Table 4. Changes on the micro-hardness and elastic modulus of S136 die steel by SLM before and after heat treatment

测试时间 位置 弹性模量变化幅度/% 显微硬度变化幅度/% 热处理前 熔池法向 7.15 19.87 热处理后 X轴方向(5列) 4.02 7.19 热处理后 Y轴方向(5行) 3.96 2.89 注:变化幅度=[(最大值‒最小值)/最大值]×100% -

[1] Wang H J, Cui Z W, Sun F, et al. Superalloy GH4169 complicated components prepared by selective laser melting forming technique. Powder Metall Technol, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009王会杰, 崔照雯, 孙峰, 等. 激光选区熔化成形技术制备高温合金GH4169复杂构件. 粉末冶金技术, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009 [2] Dong P, Chen J L. Current status of selective laser melting for aerospace applications abroad. Aerosp Manuf Technol, 2014(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-HTGY201401001.htm董鹏, 陈济轮. 国外选区激光熔化成形技术在航空航天领域应用现状. 航天制造技术, 2014(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-HTGY201401001.htm [3] Chen S, Tao F H, Jia C Z, et al. Research on selective laser melting forming process and property of H13 die steel. Hot Working Technol, 2017, 46(10): 162 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201710043.htm陈帅, 陶凤和, 贾长治, 等. H13模具钢选区激光熔化成型工艺及其性能研究. 热加工工艺, 2017, 46(10): 162 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201710043.htm [4] Ren W, Zhang G G, Xu Y X. Performance of 4Cr13 die steel by selective laser melting. China Pet Mach, 2016, 44(11): 107 https://www.cnki.com.cn/Article/CJFDTOTAL-SYJI201611022.htm任武, 张刚刚, 徐云喜. 3D打印选区激光熔化成形4Cr13模具钢及性能研究. 石油机械, 2016, 44(11): 107 https://www.cnki.com.cn/Article/CJFDTOTAL-SYJI201611022.htm [5] Zhang S, Wei Q S, Cheng L Y, et al. Effects of scan line spacing on pore characteristics and mechanical properties of porous Ti6Al4V implants fabricated by selective laser melting. Mater Des, 2014, 63: 185 doi: 10.1016/j.matdes.2014.05.021 [6] Wen S F, Li S, Wei Q S, et al. Effect of molten pool boundaries on the mechanical properties of selective laser melting parts. J Mater Process Technol, 2014, 214(11): 2660 doi: 10.1016/j.jmatprotec.2014.06.002 [7] Wen S F, Wu X L, Zhou Y, et al. Microstructure and property of S136 mould steel fabricated by selective laser melting. J Huazhong Univ Sci Technol Nat Sci, 2018, 46(2): 51 https://www.cnki.com.cn/Article/CJFDTOTAL-HZLG201802010.htm文世峰, 吴雪良, 周燕, 等. 激光选区熔化成形S136模具钢的成形性能研究. 华中科技大学学报(自然科学版), 2018, 46(2): 51 https://www.cnki.com.cn/Article/CJFDTOTAL-HZLG201802010.htm [8] Zhao X, Wei Q S, Song B, et al. Fabrication and characterization of AISI 420 stainless steel using selective laser melting. Mater Manuf Process, 2015, 30(11): 1283 doi: 10.1080/10426914.2015.1026351 [9] Liu B, Tan J H, Wu C L. Design of injection mould with conformal cooling channel based on 3D printing. Eng Plast Appl, 2015, 43(10): 71 doi: 10.3969/j.issn.1001-3539.2015.10.014刘斌, 谭景焕, 吴成龙. 基于3D打印的随形冷却水道注塑模具设计. 工程塑料应用, 2015, 43(10): 71 doi: 10.3969/j.issn.1001-3539.2015.10.014 [10] Wang Y, Yu K M, Wang C C L, et al. Automatic design of conformal cooling circuits for rapid tooling. Comput-Aided Des, 2011, 43(8): 1001 doi: 10.1016/j.cad.2011.04.011 [11] Dang X P, Park H S. Design of U-shape milled groove conformal cooling channels for plastic injection mold. Int J Precis Eng Manuf, 2011, 12(1): 73 doi: 10.1007/s12541-011-0009-8 [12] Shan Z D, Yang L N, Rong W J, et al. The study on parts' interlayer binding during three-dimensional printing based on metal fused and deposition. Mach Des Manuf, 2016(8): 135 doi: 10.3969/j.issn.1001-3997.2016.08.037单忠德, 杨立宁, 戎文娟, 等. 熔融堆积3D打印成形金属件层间结合研究. 机械设计与制造, 2016(8): 135 doi: 10.3969/j.issn.1001-3997.2016.08.037 [13] He Y. Study on Rapid Manufacturing of Hard Injection Mold with Conformal Cooling Channels [Dissertation]. Wuhan: Hubei University of Technology, 2012何寅. 随形冷却水道注塑硬模快速制造方法研究[学位论文]. 武汉: 湖北工业大学, 2012 [14] Zhang X L, Qi H, Wei Q S. Experimental study of selective laser melted AlSi12. Appl Laser, 2013, 33(4): 391 https://www.cnki.com.cn/Article/CJFDTOTAL-YYJG201304008.htm张骁丽, 齐欢, 魏青松. 铝合金粉末选择性激光熔化成形工艺优化试验研究. 应用激光, 2013, 33(4): 391 https://www.cnki.com.cn/Article/CJFDTOTAL-YYJG201304008.htm [15] Song B, Zhao X, Li S, et al. Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review. Front Mech Eng, 2015, 10(2): 111 doi: 10.1007/s11465-015-0341-2 -

下载:

下载: