Effect of alloy elements on microstructures and properties of Fe-based matrixes for diamond segment

-

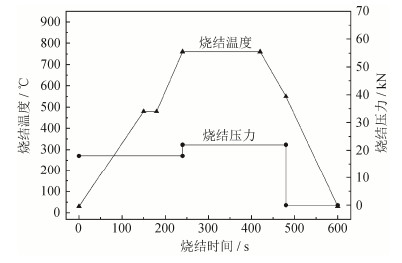

摘要: 选取Fe、Cu、Sn、Ni四种金属粉末作为烧结金刚石节块的胎体材料,设计混料试验预测成分变化对胎体性能的影响规律。结果表明:胎体中主要含α-Fe相、γ(Fe,Ni)相、Cu13.7Sn固溶体和Cu3Sn化合物。随Sn质量分数的升高,Cu13.7Sn固溶体减少,脆性Cu3Sn相增多,当Sn质量分数增大到一定程度后,组织中Cu13.7Sn固溶体全部转化成Cu3Sn脆性相,因此,胎体硬度先增高后趋于稳定;Sn质量分数越高,胎体中脆性相越多,割裂基体,胎体抗弯强度下降。Ni易固溶于Cu、Fe中,产生固溶强化,Ni质量分数升高,胎体硬度和抗弯强度均有一定程度的提高;在Sn质量分数较低时,Cu质量分数越高,Cu13.7Sn固溶体量越多,胎体硬度下降;在Sn质量分数较高时,Cu质量分数越高,组织中脆性Cu3Sn相量越多,胎体硬度提高。Cu易与Ni、Fe形成置换式固溶体,产生固溶强化作用,Cu质量分数的升高对胎体抗弯强度有一定程度的提高。Abstract: Fe-based matrixes for diamond segments were produced by Fe, Cu, Sn, and Ni powders. The mixture experiment was designed to predict the effect of element content on the matrixes performance. In the results, the matrix consists of α-Fe phase, γ(Fe, Ni) phase, Cu13.7Sn solid solution, and the brittle phase of Cu3Sn compounds. With the increase of Sn mass fraction, the content of Cu13.7Sn solid solution by mass decreases, and the content of Cu3Sn brittle phase by mass increases. When the Sn mass fraction increases to a certain extent, all the Cu13.7Sn solid solution in microstructures is transformed into Cu3Sn brittle phase, resulting that the matrix hardnes increases first and then tends to be stable. The higher the Sn mass fraction is, the more brittle phases in the matrix are, which will separate the matrix and lower the bending strength. Ni has the effect of solution strengthening in Cu and Fe, therefore the hardness and bending strength of the matrix are improved with the increase of Ni content by mass. At the lower Sn content by mass, the content of Cu13.7Sn solid solution by mass increases with the increase of Cu content, resulting in the lower hardness of the matrix. At the higher Sn content by mass, the content of Cu3Sn brittle phase by mass increases with the increase of Cu content, resulting in the higher hardness. Cu has the effect of solution strengthening in Ni and Fe, thus improving the bending strength of the matrix.

-

Key words:

- Fe-based matrixes /

- mixture experiment /

- hardness /

- bending strength

-

表 1 极端顶点法的胎体配方试验设计及结果

Table 1. Experimental design and results of extreme vertex method for the diamond segment matrixes

试验

编号元素质量分数/% HRB,y1 抗弯强度,y2/MPa Fe,x1 Cu,x2 Sn,x3 Ni,x4 1# 0.720 0.20 0.05 0.030 95.57 1092.26 2# 0.670 0.20 0.05 0.080 95.86 1213.15 3# 0.620 0.20 0.15 0.030 97.96 377.14 4# 0.570 0.20 0.15 0.080 101.94 398.28 5# 0.620 0.30 0.05 0.030 92.43 1126.38 6# 0.570 0.30 0.05 0.080 95.51 1131.42 7# 0.520 0.30 0.15 0.030 98.93 502.28 8# 0.470 0.30 0.15 0.080 103.54 542.18 9# 0.645 0.20 0.10 0.055 99.75 674.83 10# 0.545 0.30 0.10 0.055 98.31 926.00 11# 0.645 0.25 0.05 0.055 95.12 1138.58 12# 0.545 0.25 0.15 0.055 99.67 400.07 13# 0.62 0.25 0.10 0.030 98.94 797.03 14# 0.57 0.25 0.10 0.080 97.72 827.02 15# 0.595 0.25 0.10 0.055 100.29 755.78 表 2 胎体洛氏硬度与抗弯强度的实验值和计算值

Table 2. Experimental and calculated values of Rockwell hardness and bending strength of the matrixes

试验编号 硬度,HRB 抗弯强度/MPa 实验值 计算值 误差/% 实验值 计算值 误差/% 1# 95.57 95.88 0.32 1092.26 1098.05 0.53 2# 95.86 95.87 0.01 1213.15 1181.94 2.57 3# 97.96 98.57 0.62 377.14 338.75 10.18 4# 101.94 101.17 0.76 398.28 390.19 2.03 5# 92.43 93.04 0.66 1126.38 1137.68 1.00 6# 95.51 94.74 0.80 1131.42 1173.03 3.68 7# 98.93 98.76 0.17 502.28 536.70 6.85 8# 103.54 103.07 0.45 542.18 539.60 0.48 9# 99.75 99.58 0.17 674.83 746.73 10.65 10# 98.31 99.11 0.81 926.00 841.25 9.15 11# 95.12 94.96 0.17 1138.58 1111.08 2.42 12# 99.67 100.47 0.80 400.07 414.71 3.66 13# 98.94 97.57 1.38 797.03 783.90 1.64 14# 97.72 99.72 2.05 827.02 827.29 0.03 15# 100.29 99.03 1.26 755.78 781.49 3.40 图 8中位置 元素原子数分数/% Fe Cu Sn Ni 1 93.73 2.79 0.40 3.09 2 88.96 3.45 1.11 6.49 3 2.64 85.03 10.91 1.43 4 1.79 62.11 27.82 7.56 5 1.96 87.62 8.11 2.31 6 4.46 61.69 25.02 8.83 7 3.71 86.75 7.30 2.23 8 2.61 54.05 26.14 17.19 9 3.21 63.75 25.93 7.10 10 5.15 83.43 10.60 0.82 11 5.68 63.39 25.97 4.97 12 3.12 81.63 11.63 3.62 13 1.73 59.49 28.76 10.01 14 2.38 86.23 9.94 1.45 15 2.15 67.07 24.50 6.28 -

[1] Jia C C, Song Y Q, Yu M, et al. Effects of rare earth element lanthanum on the microstructure of copper matrix diamond tool materials. Rare Met, 2002, 21(2): 90 http://qikan.cqvip.com/Qikan/Article/Detail?id=8390803 [2] Long W M, Zhu K, Qiao P X, et al. Study on the welding technology of diamond saw blade. Diamond Abras Eng, 2002, 129(3): 27 doi: 10.3969/j.issn.1006-852X.2002.03.006龙伟民, 朱坤, 乔培新, 等. 金刚石锯片焊接技术的研究. 金刚石与磨料磨具工程, 2002, 129(3): 27 doi: 10.3969/j.issn.1006-852X.2002.03.006 [3] Wang L, Guo S H, Gao J Y, et al. Microwave sintering behavior of FeCuCo based metallic powder for diamond alloy tool bit. J Alloys Compd, 2017, 727: 94 doi: 10.1016/j.jallcom.2017.08.132 [4] Costa M M, Flores P, Pereira D, et al. Nickel-cobalt-based materials for diamond cutting tools. Int J Adv Manuf Technol, 2018, 95(1-4): 1059 doi: 10.1007/s00170-017-1226-9 [5] Oliveira F A C, Anjinho C A, Coelho A, et al. PM materials selection: The key for improved performance of diamond tools. Met Powder Rep, 2017, 72(5): 339 doi: 10.1016/j.mprp.2016.04.002 [6] Liu Y B, Xu Q, Xu L. Characteristics, status analysis and development trend of metal powders for diamond tools. Powder Metall Ind, 2017, 27(4): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201704001.htm刘一波, 徐强, 徐良. 金刚石工具用金属粉末的特性、现状分析和发展趋势. 粉末冶金工业, 2017, 27(4): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201704001.htm [7] Damiri S, Pouretedal H R, Bakhshi O. An extreme vertices mixture design approach to the optimization of methylal production process using p-toluenesulfonic acid as catalyst. Chem Eng Res Des, 2016, 112: 155 doi: 10.1016/j.cherd.2016.06.012 [8] Guan Y N. Mixture Experimental Design. Shanghai: Shanghai Scientific & Technical Publishers, 1990关颖男. 混料试验设计. 上海: 上海科学技术出版社, 1990 [9] Huang P Y. Theory of Powder Metallurgy. 2nd Ed. Beijing: Metallurgical Industry Press, 2004黄培云. 粉末冶金原理. 2版. 北京: 冶金工业出版社, 2004 [10] Fan J L, Huang B Y, Qu X H, et al. Densification mechanism of liquid phase sintered tungsten heavy alloy during initial solid state sintering stage. Chin J Nonferrous Met, 1998, 8(Suppl 1): 36 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ8S1.006.htm范景莲, 黄伯云, 曲选辉, 等. 液相烧结高比重合金早期固相烧结阶段的致密化机理. 中国有色金属学报, 1998, 8(增刊1): 36 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ8S1.006.htm [11] Dai Q L, Wu H Z. Research on Fe-based matrix of diamond saw-blade. Diamond Abras Eng, 2000, 118(4): 19 doi: 10.3969/j.issn.1006-852X.2000.04.005戴秋莲, 吴惠贞. 铁基金刚石圆锯片胎体材料的研究. 金刚石与磨料磨具工程, 2000, 118(4): 19 doi: 10.3969/j.issn.1006-852X.2000.04.005 -

下载:

下载: