-

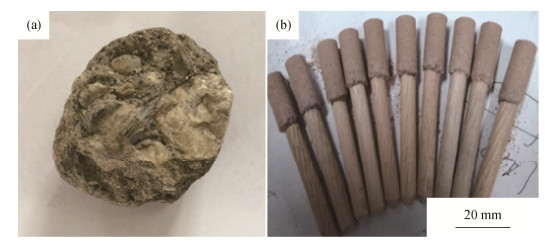

摘要: 为了解决盾构施工的泥饼问题,利用火焰喷涂在Q345钢板表面制备了石墨-镍涂层,通过摩擦磨损试验分析了涂层和无涂层试样与泥岩渣土的摩擦行为,研究了石墨-镍涂层对摩擦系数、表面磨损量和表面磨痕的影响。结果表明,干摩擦条件下,泥岩渣土与无涂层表面和涂层表面的摩擦系数分别为0.4和0.3;湿摩擦条件下,泥岩渣土与无涂层表面和涂层表面的摩擦系数分别为0.25和0.05。随着载荷从50 g增加到500 g,湿摩擦条件下涂层表面磨损量增加缓慢,干摩擦条件下涂层表面磨损量呈台阶式增加;在干摩擦条件下,随载荷增加,磨痕宽度和深度增加,局部出现犁沟形态。现场试验结果证实,滚刀刀桶端面火焰喷涂石墨-镍涂层能够有效抑制盾构在泥岩地质层施工过程中的刀盘结泥现象。Abstract: The graphite-nickel coatings on the surface of Q345 steel plates were prepared by flame spraying to solve the mud-caking problems of shield tunneling. The friction behaviors of Q345 steel samples with and without graphite-nickel coatings against mudstone compacts were analyzed by friction-wear tests, and the influences of graphite-nickel coatings on the friction coefficient, wear loss, wear scars were systemically studied. The results show that, the dry-friction coefficients of Q345 steel samples with and without graphite-nickel coatings against mudstone compacts are 0.4 and 0.3, respectively, and the wet-friction coefficients are 0.25 and 0.05, respectively. As the load increasing from 50 to 500 g, the wear loss of samples with coating increases slowly under the wet friction condition; while it takes a step-change upward under the dry friction condition. Under the dry friction condition, both width and depth of wear scar increase as increasing the load, and the furrows occur locally. The in-situ testing proves that the flame sprayed graphite-nickel coatings on the end surfaces of disc cutter barrels can effectively inhibit the mud-caking phenomena during shield tunneling in mudstone layers.

-

Key words:

- coatings /

- mudstone /

- friction /

- wear /

- shield tunneling

-

表 1 摩擦磨损试验工艺参数

Table 1. Process parameters of friction-wear test

试件类型 载荷/ g 摩擦环境 涂层、无涂层 50、100、200、300、400、500 干摩擦、湿摩擦 表 2 试验用泥岩渣土的物质组成(质量分数)

Table 2. Compositions of mudstone used in friction-wear test

% 石英 方解石 钠长石 伊利石 绿泥石 50.63 2.51 15.71 15.37 15.78 -

[1] Wang M S. Tunneling by TBM/shield in China: state-of-art, problems and proposals. Tunnel Constr, 2014, 34(3): 179 https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201403001.htm王梦恕. 中国盾构和掘进机隧道技术现状、存在的问题及发展思路. 隧道建设, 2014, 34(3): 179 https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201403001.htm [2] Peng Q. Application, research and future of tunnel boring machine technology. Tunnel Constr, 2013, 33(6): 443 https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201306007.htm彭琦. 隧道掘进机技术的发展和研究现状. 隧道建设, 2013, 33(6): 443 https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201306007.htm [3] Fountaine E R. Investigations into the mechanism of soil adhesion. Eur J Soil Sci, 1954, 5(2): 251 doi: 10.1111/j.1365-2389.1954.tb02191.x [4] Wang G Y, Zhang B. Analysis of mud-cake prevention technology for earth pressure balance shield tunnel boring machine. Constr Technol, 2016, 45(Suppl 2): 222 https://www.cnki.com.cn/Article/CJFDTOTAL-SGJS2016S2053.htm王国义, 张波. 土压平衡盾构泥饼防治技术浅析. 施工技术, 2016, 45(增刊2): 222 https://www.cnki.com.cn/Article/CJFDTOTAL-SGJS2016S2053.htm [5] Li Z J, Zai Z G, Zhao K L. Causes of mud cake formation on cutter head of slurry shield and its control technology. Chin J Underground Space Eng, 2014, 10(Suppl 2): 1866 https://www.cnki.com.cn/Article/CJFDTOTAL-BASE2014S2022.htm李志军, 翟志国, 赵康林. 泥水盾构刀盘结泥饼形成原因及防治技术. 地下空间与工程学报, 2014, 10(增刊2): 1866 https://www.cnki.com.cn/Article/CJFDTOTAL-BASE2014S2022.htm [6] Yang Z Y, Cheng X W, Jiang Y S. Analysis of cutterhead torque calculation and its influence factors for slurry balance shield. J Railway Eng Soc, 2016(5): 59 doi: 10.3969/j.issn.1006-2106.2016.05.011杨志勇, 程学武, 江玉生. 泥水平衡盾构刀盘扭矩计算及其影响因素分析. 铁道工程学报, 2016(5): 59 doi: 10.3969/j.issn.1006-2106.2016.05.011 [7] Zuo C F, Tang D G, Rong X L, et al. State recognition of cutter wear based on frictional torque parameters of cutterhead. Tunnel Constr, 2016, 36(3): 344 https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201603021.htm左翠凤, 唐德高, 戎晓力, 等. 基于刀盘摩擦扭矩参数的刀具磨损状态识别. 隧道建设, 2016, 36(3): 344 https://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201603021.htm [8] Zhou S H, Li X, Ji C, et al. Back-fill grout experimental test for discharged soils reuse of the large-diameter size slurry shield tunnel. KSCE J Civ Eng, 2017, 21(3): 725 doi: 10.1007/s12205-016-0856-z [9] Bryan P J, Gutshall P L, Taylor L H. A study of mechanisms of graphite friction and wear. Wear, 1964, 7(1): 118 doi: 10.1016/0043-1648(64)90083-3 [10] Li J L, Xiong D S. Tribological behavior of graphite-containing nickel-based composite as function of temperature, load and counterface. Wear, 2009, 266(1-2): 360 doi: 10.1016/j.wear.2008.06.020 [11] Yang J F, Jiang Y, Hardell J, et al. Influence of service temperature on tribological characteristics of self-lubricant coatings: A review. Front Mater Sci, 2013, 7(1): 28 doi: 10.1007/s11706-013-0190-z [12] Rawal S P. Metal-matrix composites for space applications. JOM, 2001, 53(4): 14 doi: 10.1007/s11837-001-0139-z [13] Sass I, Burbaum U. A method for assessing adhesion of clays to tunnelling machines. Bull Eng Geol Environ, 2010, 69(4): 671 doi: 10.1007/s10064-010-0304-0 [14] Ding H D, Fu S L, Zhu Y L, et al. Failure analyzing of self-lubrication material. Powder Metall Technol, 2001, 19(5): 270 doi: 10.3321/j.issn:1001-3784.2001.05.004丁华东, 傅苏黎, 朱有利, 等. 自润滑材料滑动摩擦失效分析. 粉末冶金技术, 2001, 19(5): 270 doi: 10.3321/j.issn:1001-3784.2001.05.004 [15] Wu J, Yuan D J, Li X G, et al. Analysis on wear mechanism and prediction of shield cutter. China J Highway Ttransport, 2017, 30(8): 109 doi: 10.3969/j.issn.1001-7372.2017.08.012吴俊, 袁大军, 李兴高, 等. 盾构刀具磨损机理及预测分析. 中国公路学报, 2017, 30(8): 109 doi: 10.3969/j.issn.1001-7372.2017.08.012 [16] Wen S Z, Huang P. Principles of Tribology. Beijing: Tsinghua University Press, 2002温诗铸, 黄平. 摩擦学原理. 北京: 清华大学出版社, 2002 -

下载:

下载: