Research on the microstructures and mechanical properties of high speed steel M2 produced by spray forming and traditional melting

-

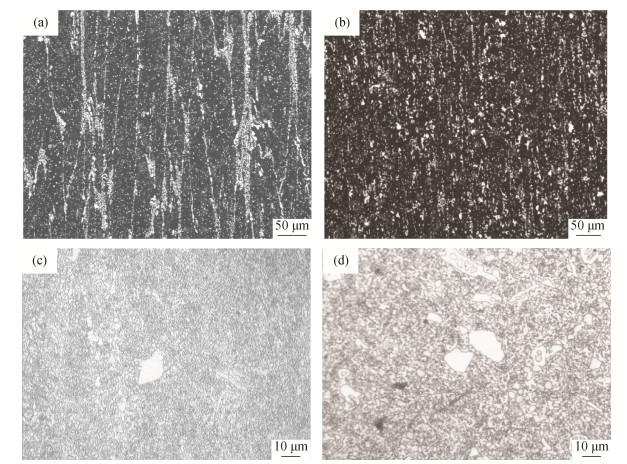

摘要: 通过喷射成形和传统熔炼(中频冶炼+电渣重熔)两种工艺生产了高速钢M2(W6Mo5Cr4V2)试样,利用金相显微镜和M-200磨损试验机对同规格同位置的两种试样的退火组织、非金属夹杂物、淬回火硬度、显微组织和力学性能进行了研究。结果表明,喷射成形M2试样的碳化物分布均匀、尺寸细小,传统熔炼M2试样碳化物呈条带状分布;在相同热处理制度和位置下,喷射成形M2试样的回火硬度与传统熔炼M2试样相当;喷射成形M2试样的耐磨性要比传统M2试样提高约41%;喷射成形M2试样中尺寸大于2μm的MC类碳化物数量明显多于传统M2试样,使得在同等硬度下喷射成形M2试样的耐磨性能要优于传统M2试样。由此可知,喷射成形M2试样的组织及力学性能均优于传统熔炼M2试样,喷射成形技术具有工艺先进性。Abstract: Two kinds of high speed steel specimens (M2, W6Mo5Cr4V2) were prepared by spray forming and traditional melting, respectively. The annealing structures, non-metal inclusions, hardness after quenching and tempering, microstructures, and mechanical properties of M2 specimens in the same size at the same location were studied by metallographic microscope and M-200 wear tester. In the results, the carbides in spray formed M2 specimens show more uniform distribution and smaller size, and the carbides in traditional melted M2 specimens are present as the zonal distribution. In the same heat treatment process, the tempering hardness of M2 specimens prepared by spray forming and traditional melting is similar at the same location. Compared with the traditional melted M2 specimens, the wear resistance of spray formed M2 specimens is increased by ~41%. The number of MC carbides in spray formed M2 specimens with the size more than 2μm is apparently higher than that in the traditional melted M2 specimens, resulting in the higher wear resistance of spray formed M2 specimens in the same hardness. It can be seen that the microstructures and mechanical properties of spray formed M2 specimens are better than those of the traditional melted M2 specimens, showing the advancement of spray forming technology.

-

Key words:

- spray forming /

- traditional melting /

- high speed steel /

- microstructures /

- mechanical properties

-

表 1 试验用钢材化学成分(质量分数)

Table 1. Chemical composition of testing steels

% 试样材料 C Cr Mo V W HSF620 0.91 4.36 5.27 2.12 5.7 传统M2 0.88 4.1 4.77 1.86 6.11 表 2 试样1/4直径处非金属夹杂物

Table 2. Non-metal inclusion at 1/4 diameter of specimens

钢材 非金属夹杂物级别 HSF620 B0.5D0.5DS1 传统M2 B0.5DS1 -

[1] Jiang C M, Gao Y Z, Hu Y P, et al. The present status and future development of semisolid forming of spray deposition materials. J Beijing Union Univ, 2001, 15(Supple 1): 89 https://www.cnki.com.cn/Article/CJFDTOTAL-BJLH2001S1022.htm姜春梅, 高元植, 胡宜平, 等. 喷射沉积合金的半固态成形的研究现状与发展前景. 北京联合大学学报, 2001, 15(增刊1): 89 https://www.cnki.com.cn/Article/CJFDTOTAL-BJLH2001S1022.htm [2] Zhou C D, Zhu X F, Fan J F, et al. Probability of production of super high alloyed high speed steel by spray forming instead of powder metallurgy. Chin J Rare Met, 2006, 30(Spec Issue): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS2006S1014.htm周灿栋, 祝新发, 樊俊飞, 等. 喷射成形取代粉末冶金生产超高合金高速钢的可行性研究. 稀有金属, 2006, 30(专辑): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS2006S1014.htm [3] Cui C S, Zhang J G. Research progress of spray forming technology for the manufacture of high performance iron and steel materials (Ⅰ)—Principle, characteristics and development status. Shanghai Met, 2012, 34(2): 42 doi: 10.3969/j.issn.1001-7208.2012.02.010崔成松, 章靖国. 喷射成形快速凝固技术制备高性能钢铁材料的研究进展(一)—喷射成形技术的原理、特点及发展现状. 上海金属, 2012, 34(2): 42 doi: 10.3969/j.issn.1001-7208.2012.02.010 [4] Li R D, Liu J F. Development and application of spray forming technology at home and abroad. Foundry, 2009, 58(8): 797 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZZZ200908008.htm李荣德, 刘敬福. 喷射成形技术国内外发展与应用概况. 铸造, 2009, 58(8): 797 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZZZ200908008.htm [5] Chen J C, Sun J L. Present-day research situation and prospect of spring forming. J Kunming Univ Sci Technol, 1997, 22(1): 47 https://www.cnki.com.cn/Article/CJFDTOTAL-KMLG701.008.htm陈敬超, 孙加林. 喷射成形技术的研究现状与展望. 昆明理工大学学报, 1997, 22(1): 47 https://www.cnki.com.cn/Article/CJFDTOTAL-KMLG701.008.htm [6] Hua Y L, Wang H L. Development and application of spray forming technology. Hot Working Technol, 2010, 39(21): 192 doi: 10.3969/j.issn.1001-3814.2010.21.063滑有录, 王海龙. 喷射成形技术的发展与应用. 热加工工艺, 2010, 39(21): 192 doi: 10.3969/j.issn.1001-3814.2010.21.063 [7] Zhang Y A, Xiong B Q, Shi L K. Research on spray forming technology and products. Mater Rev, 2002, 16(3): 11 doi: 10.3321/j.issn:1005-023X.2002.03.004张永安, 熊柏青, 石力开. 喷射成形技术产品的研究现状. 材料导报, 2002, 16(3): 11 doi: 10.3321/j.issn:1005-023X.2002.03.004 [8] Song X S, Zhou C D, Xuan F Z, et al. Type and morphology of carbide in spray formed high speed steel. Mater Mech Eng, 2009, 33(3): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC200903018.htm宋学森, 周灿栋, 轩福贞, 等. 喷射成形高速钢中碳化物的类型与形貌. 机械工程材料, 2009, 33(3): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC200903018.htm [9] Zhang Y, Zhang G Q, Li Z, et al. Research on properties of high speed steel prepared by spray forming. J Aeronaut Mater, 2008, 28(6): 32 doi: 10.3969/j.issn.1005-5053.2008.06.007张勇, 张国庆, 李周, 等. 喷射成形高速钢沉积坯性能分析. 航空材料学报, 2008, 28(6): 32 doi: 10.3969/j.issn.1005-5053.2008.06.007 [10] Wang J, Xu Z, Shi H S, et al. Microstructure and process of as-sprayed UHCS. J Mater Sci Eng, 2003, 21(5): 660 doi: 10.3969/j.issn.1673-2812.2003.05.009王军, 徐政, 史海生, 等. 喷射成形超高碳钢的微观组织与工艺研究. 材料科学与工程学报, 2003, 21(5): 660 doi: 10.3969/j.issn.1673-2812.2003.05.009 [11] Wei K, Xu Y, Liu X, et al. Microstructure and properties of high vanadium steel with 9% vanadium fabricated by spray forming-hot isostatic pressing. Powder Metall Ind, 2012, 22(3): 21 doi: 10.3969/j.issn.1006-6543.2012.03.004魏宽, 徐轶, 刘宪, 等. 喷射成形—热等静压9V高钒钢的组织与性能研究. 粉末冶金工业, 2012, 22(3): 21 doi: 10.3969/j.issn.1006-6543.2012.03.004 [12] Lu L, Huang J F, Hou L G, et al. Effect of niobium on the microstructure and properties of spray-formed M3: 2 high speed steel. J Univ Sci Technol Beijing, 2014, 36(10): 1292 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201410003.htm卢林, 黄进峰, 侯陇刚, 等. 铌对喷射成形M3: 2型高速钢组织和性能的影响. 北京科技大学学报, 2014, 36(10): 1292 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201410003.htm [13] Yu Y P, Huang J F, Cui H, et al. Microstructural characterization of carbides in spray-formed M3 high speed steel and its evolution during heating process. J Univ Sci Technol Beijing, 2012, 34(7): 793 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201207011.htm于一鹏, 黄进峰, 崔华, 等. 喷射成形M3型高速钢碳化物组织特征与加热过程演化. 北京科技大学学报, 2012, 34(7): 793 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201207011.htm [14] Xu Y, Ge C C, Wei K, et al. Research on preparation technology of high-vanadium HSS by spray forming. Powder Metall Technol, 2012, 30(1): 22 doi: 10.3969/j.issn.1001-3784.2012.01.005徐轶, 葛昌纯, 魏宽, 等. 喷射成形高钒高速钢环坯制备技术研究. 粉末冶金技术, 2012, 30(1): 22 doi: 10.3969/j.issn.1001-3784.2012.01.005 [15] Liu D D, Zhang G S, Wei S Z, et al. Investigation of wear performance of high vanadium high speed steel. Foundry Technol, 2013, 34(2): 135 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201302004.htm刘冬冬, 张国赏, 魏世忠, 等. 高钒高速钢磨损性能的研究现状. 铸造技术, 2013, 34(2): 135 https://www.cnki.com.cn/Article/CJFDTOTAL-ZZJS201302004.htm -

下载:

下载: