-

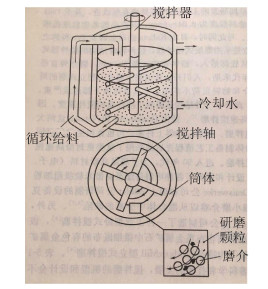

摘要: 通过搅拌球磨的方式在不同球磨助剂及球磨时间下,利用不同比表面积的前驱体磨制了片状银粉。采用激光粒度分布仪、扫描电子显微镜、比表面测试仪及松装、振实密度测试仪等设备研究了片状银粉的物理性能及导电性。结果表明:在球磨介质、料球比确定的前提下,使用比表面积为0.50 m2/g左右、分散性良好的类球形银粉为前驱体,以硬脂酸为球磨助剂,控制球磨时间为12 h,可制备得到方阻值不高于15 Ω/□的片状银粉,该银粉适用于导电银浆。Abstract: The flake silver powders were grinded by stirring ball milling with different milling aids at different milling times, using the precursors in different specific surface areas. The physical properties and electrical conductivity of flake silver powders were investigated by laser particle size distribution (PSD) instrument, scanning electron microscope (SEM), specific surface area (SSA) tester, and the test devices for apparent density and tap density. In the results, when the ball mill medium and the ball-to-powder weight ratio are determined, the flake silver powders with the sheet resistance no more than 15 Ω/□ can be prepared by using spherical silver powders as the precursor with the excellent dispersibility at the specific surface area of~0.50 m2/g, the stearic acid is chosen as the milling aids, and the milling time is controlled as 12 h. The prepared flake silver powders are suitable for the conductive silver paste production.

-

Key words:

- stirring ball milling /

- flake silver powder /

- precursor /

- milling aids /

- milling time

-

表 1 不同比表面积的球磨前驱体磨制后银粉物理性能

Table 1. Physical properties of silver powders prepared by ball milling precursors in different specific surface areas

型号 松装密度/(g·cm‒3) 比表面积/(m2·g‒1) 黏度/(MPa·s‒1) 方阻/(mΩ·□‒1) 印刷线条外观 AF 0.53 2.49 36.1 17.69

BF 0.61 1.68 25.5 12.41

表 2 不同球磨助剂磨制后银粉性能参及导电性数

Table 2. Properties and electrical conductivity of silver powders prepared by different milling aids

助剂 松装密度/(g·cm‒3) 比表面积/(m2·g‒1) D4, 3/μm 方阻/(mΩ·□‒1) 油酸 1.09 1.31 4.596 20.71 硬脂酸 0.70 1.50 3.573 13.43 -

[1] Tan F B, Zhao L, Sun W T. A conductive polymer — Silver paste. Precious Met, 1991, 12(4): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-GJSZ199104006.htm谭富彬, 赵玲, 孙文通. 聚合物导电银浆. 贵金属, 1991, 12(4): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-GJSZ199104006.htm [2] Huang F C, Li W L, Xiong Q F, et al. Preparation of flake silver powders with high diameter-to-thickness ratio. Precious Met, 2012, 33(2): 30 doi: 10.3969/j.issn.1004-0676.2012.02.006黄富春, 李文琳, 熊庆丰, 等. 高径厚比片状银粉的制备. 贵金属, 2012, 33(2): 30 doi: 10.3969/j.issn.1004-0676.2012.02.006 [3] Tan F B, Zhao L, Liu L, et al. Characteristics and electrical properties of flake-like silver powder and paste. Precious Met, 1999, 20(2): 10 doi: 10.3969/j.issn.1004-0676.1999.02.002谭富彬, 赵玲, 刘林, 等. 片状银粉的特性及其电性能. 贵金属, 1999, 20(2): 10 doi: 10.3969/j.issn.1004-0676.1999.02.002 [4] Liu J, Song Y H, Lan X Z. Preparation of nanometer flake silver powder. Non-ferrous Met, 2002, 54(Suppl): 64 https://www.cnki.com.cn/Article/CJFDTOTAL-GJSZ201502006.htm刘江, 宋永辉, 兰新哲. 片状银粉的制备研究. 有色金属, 2002, 54(增刊): 64 https://www.cnki.com.cn/Article/CJFDTOTAL-GJSZ201502006.htm [5] Ye H Q, Su Z, Zhou Y H, et al. Application of flaky metal powders to pigments and electronic paste. China Powder Sci Technol, 2004(1): 34 doi: 10.3969/j.issn.1008-5548.2004.01.010叶红齐, 苏周, 周永华, 等. 片状金属粉体在颜料及电子浆料中的应用. 中国粉体技术, 2004(1): 34 doi: 10.3969/j.issn.1008-5548.2004.01.010 [6] Li H J. Research and progress of ultrafine stirring mill. Light Ind Sci Technol, 2017(7): 72 https://www.cnki.com.cn/Article/CJFDTOTAL-GXQG201307041.htm李慧娟. 超细搅拌磨机的研究现状和进展. 轻工技术, 2017(7): 72 https://www.cnki.com.cn/Article/CJFDTOTAL-GXQG201307041.htm [7] Yang H M, Tang A D, Qiu G Z. Application of stirred mill in ultrafine powder fabrication. Multipurp Utiliz Min Resour, 1997(1): 33 https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL199701008.htm杨华明, 唐爱东, 邱冠周. 搅拌磨在超细粉制备中的应用. 矿产综合利用, 1997(1): 33 https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL199701008.htm [8] Wang Y M. Technical Manual of Powder. 1st Ed. Beijing: Chemical Industry Press, 2004王燕民. 粉体技术手册. 1版. 北京: 化学工业出版社, 2004 [9] Li X L, Huang F C, Li W L, et al. Research on loose packed flake silver powders with low apparent density. Precious Met, 2012, 33(1): 16 doi: 10.3969/j.issn.1004-0676.2012.01.004李晓龙, 黄富春, 李文琳, 等. 低松装密度片状银粉的研究. 贵金属, 2012, 33(1): 16 doi: 10.3969/j.issn.1004-0676.2012.01.004 [10] Gan W P, Gan M, Liu Y. Study on the modification of flake silver powder by high energy ball milling. Mater Rep, 2007, 21(Spec Ⅷ): 325 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2007S1099.htm甘为平, 甘梅, 刘妍. 高能球磨对片状银粉的改性研究. 材料导报, 2007, 21(专辑Ⅷ): 325 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2007S1099.htm [11] Wu H B, Meng S Y, Tang Y X. Preparation of small size particle flake silver powder. Electron Process Technol, 2008, 29(5): 286 doi: 10.3969/j.issn.1001-3474.2008.05.011吴海斌, 孟淑媛, 唐元勋. 小粒径片状银粉的制备. 电子工艺技术, 2008, 29(5): 286 doi: 10.3969/j.issn.1001-3474.2008.05.011 [12] Liu Y Q. Preparation of flake silver powder for electronic paste. Screen Printing, 2006(2): 24 https://www.cnki.com.cn/Article/CJFDTOTAL-SWYS200602009.htm刘永庆. 电子浆料用片状银粉的制备. 丝网印刷, 2006(2): 24 https://www.cnki.com.cn/Article/CJFDTOTAL-SWYS200602009.htm [13] Zhang J J, Wang Z F, Zhang X J, et al. Effect of processing parameters in high-energy-milling on the particle size of Mo. China Molybd Ind, 2005, 29(1): 28 doi: 10.3969/j.issn.1006-2602.2005.01.006张瑾瑾, 王志法, 张行健, 等. 高能球磨工艺对Mo颗粒尺寸的影响. 中国钼业, 2005, 29(1): 28 doi: 10.3969/j.issn.1006-2602.2005.01.006 [14] Cai X L, Lin X M, Wang G F. Ultrafine powder preparation of flake zinc by high energy milling. Non-ferrous Met, 2004, 56(3): 29 https://www.cnki.com.cn/Article/CJFDTOTAL-YOUS200403008.htm蔡晓兰, 林兴铭, 王国富. 高能球磨法制备超细鳞片状锌粉. 有色金属, 2004, 56(3): 29 https://www.cnki.com.cn/Article/CJFDTOTAL-YOUS200403008.htm [15] Zhang C X. The researches in technology of high-energy ball mill for ultrafine tungsten powder. Jiangxi Nonferrous Met, 2005, 19(1): 33 doi: 10.3969/j.issn.1674-9669.2005.01.009张彩霞. 超细钨粉高能球磨工艺的探讨. 江西有色金属, 2005, 19(1): 33 doi: 10.3969/j.issn.1674-9669.2005.01.009 -

下载:

下载: