-

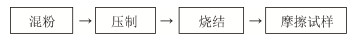

摘要: 制动摩擦材料利用运动表面相接触时所产生的摩擦阻力达到减速或终止运动目的,是运载机械中安全保障装置的重要组成部分。本文综述了半金属基、金属基及非金属基制动摩擦材料的研究现状及优缺点,介绍了熔铸法、粉末冶金法及三维编织法等制动摩擦材料制备方法,并从摩擦、磨损、热稳定性等方面分析了制动摩擦材料的关键特性。从研究状况可知,摩擦材料正向少纤维、无纤维型方向发展,高性能、环保型摩擦材料具有较大的发展优势。优化制备工艺、降低生产成本、提高性能、扩大应用领域将是未来制动摩擦材料的研究重点。Abstract: As the important components of security devices in transport machinery, the brake friction materials realize the brake and speed reduction by frictional resistance produced by surface contact. The research status, advantages, and disadvantages of brake friction materials were summarized in this paper, including semimetal-based, metal-based, and non-metallic-based brake friction materials. The preparation methods of brake friction materials were introduced as melting-casting method, powder metallurgy method, and three dimensional weave method. The key characteristics of brake friction materials were analyzed, such as friction, wear, and thermal stability. The development tendency of friction materials is fiberless, high-powered, and environmental. Optimizing the preparation process, reducing the production cost, improving the performance, and expanding the application field of brake friction materials will be the research focus in the future.

-

Key words:

- break friction material /

- preparation method /

- friction /

- wear /

- thermal stability

-

表 1 常用增强纤维的种类及性能

Table 1. Types and properties of reinforcing fibers

纤维种类 密度/(g·cm‒3) 拉伸强度/GPa 弹性模量/GPa 断裂伸长率/% 摩擦磨损 碳纤维 1.5~2.0 2~7 230~430 1.5~2.4 优 钢纤维 7.8 1.8~2.0 200 2.3 优 芳纶纤维 1.44 2.67 58 8 优 钛酸钾晶须 3.37 280 ― ― 优 -

[1] Ma H T, Zhang Y T, Yang J. Research progress of automobile braking friction materials. Mod Manuf Technol Equip, 2011(5): 76 doi: 10.3969/j.issn.1673-5587.2011.05.037马洪涛, 张勇亭, 杨军. 汽车制动摩擦材料研究进展. 现代制造技术与装备, 2011(5): 76 doi: 10.3969/j.issn.1673-5587.2011.05.037 [2] Huang F H, Wang S Q, Zhang C R, et al. A review of advanced brake disc materials. Mater Rev, 2012, 26(10): 59 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201219015.htm黄飞虎, 王思青, 张长瑞, 等. 高性能刹车材料的研究现状与发展趋势. 材料导报, 2012, 26(10): 59 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201219015.htm [3] Bernard S S, Jayakumari L S. Effect of the properties of natural resin binder in a high friction composite material. Polimeros, 2014, 24(2): 149 doi: 10.4322/polimeros.2014.038 [4] Etemadi H, Shojaei A, Jahanmard P. Effect of alumina nanoparticle on the tribological performance of automotive brake friction materials. J Reinf Plast Compos, 2014, 33(2): 166 doi: 10.1177/0731684413507011 [5] Rimdusit S, Tiptipakorn S, Jubsilp C, et al. Polybenzoxazine alloys and blends: Some unique properties and applications. React Funct Polym, 2013, 73(2): 369 doi: 10.1016/j.reactfunctpolym.2012.04.022 [6] Zhong L, Chen M Q. Research situation and development of friction material for brake pads. Synth Mater Aging Appl, 2017, 46(6): 84 https://www.cnki.com.cn/Article/CJFDTOTAL-HOCE201706018.htm钟厉, 陈梦青. 刹车片摩擦材料的研究现状与发展趋势. 合成材料老化与应用, 2017, 46(6): 84 https://www.cnki.com.cn/Article/CJFDTOTAL-HOCE201706018.htm [7] Wang Y, Zhou Y K, Nie H W. Tribological performance of semimetal friction material with different functional constituents. Non-Met Mines, 2015, 38(5): 81 doi: 10.3969/j.issn.1000-8098.2015.05.025王玥, 周元康, 聂华伟. 增强组分对半金属摩擦材料摩擦学性能的影响. 非金属矿, 2015, 38(5): 81 doi: 10.3969/j.issn.1000-8098.2015.05.025 [8] Zhang C, Wu J, Huang Z, et al. The study on tribological properties of friction material reinforced by the steel and copper fibers. Mech Des Manuf, 2017(Suppl 1): 52 https://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ2017S1014.htm张超, 吴娟, 黄镇, 等. 钢/铜混杂纤维增强摩擦材料摩擦学性能研究. 机械设计与制造, 2017(增刊1): 52 https://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ2017S1014.htm [9] Wang X F, Yin C L. Application situations of powder metallurgy friction materials and requests for raw materials. Powder Metall Ind, 2017, 27(3): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201703001.htm王秀飞, 尹彩流. 粉末冶金摩擦材料的应用现状及对原材料的要求. 粉末冶金工业, 2017, 27(3): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201703001.htm [10] Bai T Q, Wang X F, Zhong Z G, et al. Effects of friction components on friction properties of powder metallurgy friction materials. Mater Sci Eng Powder Metall, 2006, 11(6): 345 doi: 10.3969/j.issn.1673-0224.2006.06.006白同庆, 王秀飞, 钟志刚, 等. 摩擦组元对粉末冶金摩擦材料摩擦性能的影响. 粉末冶金材料科学与工程, 2006, 11(6): 345 doi: 10.3969/j.issn.1673-0224.2006.06.006 [11] Yu X, Guo Z M, Yang J, et al. Effect of Fe content and friction components on properties of copper-based powder metallurgy friction material. Powder Metall Technol, 2014, 32(1): 4 doi: 10.3969/j.issn.1001-3784.2014.01.008于潇, 郭志猛, 杨剑, 等. Fe含量及摩擦组元对铜基粉末冶金摩擦材料性能的影响. 粉末冶金技术, 2014, 32(1): 4 doi: 10.3969/j.issn.1001-3784.2014.01.008 [12] Zhou H B, Yao P P, Xiao Y L, et al. Topographical characteristics and wear mechanism of copper-based powder metallurgy friction materials reinforced by SiC particle. Chin J Nonferrous Met, 2014, 24(9): 2272 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201409011.htm周海滨, 姚萍屏, 肖叶龙, 等. SiC颗粒强化铜基粉末冶金摩擦材料的表面形貌特征及磨损机理. 中国有色金属学报, 2014, 24(9): 2272 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201409011.htm [13] Jiang G P, Yang J F, Xu Y D, et al. Effect of graphitization on microstructure and tribological properties of C/SiC composites prepared by reactive melt infiltration. Compos Sci Technol, 2008, 68(12): 2468 doi: 10.1016/j.compscitech.2008.04.025 [14] Jiang S Z, Li Z, Xiong X, et al. Preparation and microstructure of C/C‒SiC composites fabricated by warm compressed‒in situ reacted process. J Central South Univ Sci Technol, 2011, 42(6): 1588 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201106016.htm姜四洲, 李专, 熊翔, 等. 温压‒原位反应法制备C/C‒SiC复合材料及其显微结构分析. 中南大学学报(自然科学版), 2011, 42(6): 1588 https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201106016.htm [15] Li Z, Liu Y Z, Zhang B G, et al. Microstructure and tribological characteristics of needled C/C‒SiC brake composites fabricated by simultaneous infiltration of molten Si and Cu. Tribol Int, 2016, 93: 220 doi: 10.1016/j.triboint.2015.08.047 [16] Xiao P, Li Z, Xiong X, et al. Tribological behaviour and mechanism of C/C‒SiC‒Fe composites at different braking speeds. Chin J Nonferrous Met, 2009, 19(6): 1044 doi: 10.3321/j.issn:1004-0609.2009.06.011肖鹏, 李专, 熊翔, 等. 不同制动速度下C/C‒SiC‒Fe材料的摩擦磨损行为及机理. 中国有色金属学报, 2009, 19(6): 1044 doi: 10.3321/j.issn:1004-0609.2009.06.011 [17] Xu F, Feng X M, Wang Y S. Research on iron based powder metallurgy frictional materials. Hot Working Technol, 2017, 46(14): 110 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201714031.htm徐峰, 冯小明, 王永善. 铁基粉末冶金摩擦材料的研制. 热加工工艺, 2017, 46(14): 110 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201714031.htm [18] Lü Y Y. Research on Non-Metallic Friction Materials Based on 3D Braided Structure [Dissertation]. Beijing: University of Science and Technology Beijing, 2016吕莹莹. 基于三维编织结构的非金属基摩擦材料研究[学位论文]. 北京: 北京科技大学, 2016 [19] Chen D. Study on Friction and Wear Characteristics and Mechanism of Composite Surface [Dissertation]. Guangzhou: South China University of Technology, 2005陈东. 复合材料表面摩擦磨损特性与机理研究[学位论文]. 广州: 华南理工大学, 2005 [20] Zhong A W, Yao P P, Xiao Y L, et al. Tribological behaviors and reliability life of Cu-based friction materials for space applications in vacuum at room temperature. Mater Sci Eng Powder Metall, 2018, 23(1): 110 doi: 10.3969/j.issn.1673-0224.2018.01.015钟爱文, 姚萍屏, 肖叶龙, 等. 真空常温下空间用铜基粉末冶金摩擦材料的摩擦行为及可靠性寿命. 粉末冶金材料科学与工程, 2018, 23(1): 110 doi: 10.3969/j.issn.1673-0224.2018.01.015 [21] Xu X, Yang M, Zhang S W, et al. Influence of ingredient of high friction coefficient composite material on the tribological performance. Fiber Reinf Plast Compos, 2017(1): 53 doi: 10.3969/j.issn.1003-0999.2017.01.008徐祥, 杨明, 张世伟, 等. 新型高摩合成材料组分对摩擦性能的影响规律研究. 玻璃钢/复合材料, 2017(1): 53 doi: 10.3969/j.issn.1003-0999.2017.01.008 [22] Lu S J, Fu X S, Sun W T, et al. Properties of resin-based composite friction materials with different contents of modified bauxite. Mater Mech Eng, 2017, 41(1): 85 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201701018.htm卢尚健, 付雪松, 孙胃涛, 等. 不同改性矾土添加量下树脂基复合摩擦材料的性能. 机械工程材料, 2017, 41(1): 85 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201701018.htm -

下载:

下载: