Influence factors and improvement methods on the porosity of 3D printing metal materials

-

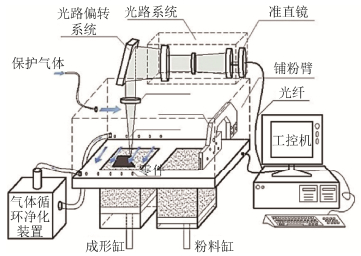

摘要: 选区激光熔融技术是精细激光快速成形技术领域中最具发展潜力的金属3D打印技术之一, 但在快速成形过程中的急速加热和快速凝固导致材料出现孔隙、裂纹等缺陷。本文介绍了对选区激光熔融技术制备金属材料孔隙率的影响因素, 包括激光功率、扫描速率、环境气氛、纳米粉末复合掺杂等; 讨论了降低孔隙率的后处理方法, 如热处理、塑性变形等, 旨在研究对3D打印金属材料孔隙率的影响规律, 从而获得性能优良的打印材料。Abstract: Selective laser melting is one of the most promising 3D printing technologies in the field of fine laser rapid prototyping.However, the rapid heating and solidification in the printing process result in the defects, such as pores and cracks.To obtain the printing materials with excellent performance, the influence factors on the porosity of 3D printing metal materials prepared by selective laser melting technology were introduced in this paper, including laser power, scanning rate, ambient atmosphere, and nanometer powder composite doping.The subsequent treatments were discussed to reduce the porosity, such as heat treatment and plastic deformation.

-

Key words:

- 3D printing /

- selective laser melting /

- porosity /

- influence factor

-

图 9 原料粉末微观结构:(a) 316L不锈钢粉末; (b)微米级TiC; (c)纳米级TiC; (d)微米级TiC+球磨316L复合粉末; (e)纳米级TiC+球磨316L复合粉末[27]

Figure 9. Microstructures of raw powders:(a) 316L stainless steel powders; (b) TiC micron-powders; (c) TiC nano-powders; (d) composite powders of TiC micron-powders and ball-milled 316L powders; (e) composite powders of TiC nano-powders and ball-milled 316L powders[27]

表 1 不同热处理工艺后的打印不锈钢316L孔隙度变化[31]

Table 1. Porosity analysis of the selective laser melted 316L stainless steel after different heat treatment processes[31]

热处理工艺 平均孔隙率/ % 孔隙率误差/ % 平均孔隙尺寸/ μm 孔隙尺寸误差/ μm 最小孔隙尺寸/ μm 最大孔隙尺寸/ μm 去应力退火 0.19 0.08 3.2 3.5 0.9 36.0 固溶+热等静压 0.08 0.03 2.8 2.3 0.9 27.1 固溶处理 0.30 0.50 16.0 14.5 2.9 83.9 -

[1] Guo C, Zhang P P, Lin F. Research advances of electron beam selective melting additive manufacturing technology. Ind Technol Innov, 2017, 4(4): 6 https://www.cnki.com.cn/Article/CJFDTOTAL-GYJS201704002.htm郭超, 张平平, 林峰.电子束选区熔化增材制造技术研究进展.工业技术创新, 2017, 4(4): 6 https://www.cnki.com.cn/Article/CJFDTOTAL-GYJS201704002.htm [2] Chen B S. Development status and trend of additive manufacturing(3D printing)application fields. Constr Mach Technol Manage, 2015(12): 38 doi: 10.3969/j.issn.1004-0005.2015.12.012陈勃生.增材制造(3D打印)应用领域发展现状及趋势.建设机械技术与管理, 2015(12): 38 doi: 10.3969/j.issn.1004-0005.2015.12.012 [3] Zeng Z, Wang L F, Yan B. Research progress of metal materials for 3D printing. Shanghai Nonferrous Met, 2016, 37(1): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-SHHA201601012.htm郑增, 王联凤, 严彪. 3D打印金属材料研究进展.上海有色金属, 2016, 37(1): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-SHHA201601012.htm [4] Wang H J, Cui Z W, Sun F, et al. Superalloy GH4169complicated components prepared by selective laser melting forming technique. Powder Metall Technol, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009王会杰, 崔照雯, 孙峰, 等.激光选区熔化成形技术制备高温合金GH4169复杂构件.粉末冶金技术, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009 [5] Wu W H, Wu K Q, Xiao Y F, et al. Effect of atomization pressure on the properties of 316L stainless steel powders used in 3D printing, Powder Metall Technol, 2017, 35(2): 83吴文恒, 吴凯琦, 肖逸凡, 等.气雾化压力对3D打印用316L不锈钢粉末性能的影响.粉末冶金技术, 2017, 35(2): 83 [6] Xiong J, Lei Y Y, Chen H, et al. Fabrication of inclined thin-walled parts in multi-layer single-pass GMAW-based additive manufacturing with flat position deposition. JMater Process Technol, 2017, 240: 397. doi: 10.1016/j.jmatprotec.2016.10.019 [7] Hildreth O J, Nassar A R, Chasse K R, et al. Dissolvable metal supports for 3D direct metal printing. 3D Print Addit Manuf, 2016, 3(2): 90. doi: 10.1089/3dp.2016.0013 [8] DebRoy T, Wei H L, Zuback J S, et al. Additive manufacturing of metallic components-process, structure and properties. Prog Mater Sci, 2018, 92: 112. [9] Wang X W. Six breakthrough points of 3D printing in the field of aerospace. World Manuf Technol Equip Market, 2018(1): 68 doi: 10.3969/j.issn.1015-4809.2018.01.012王晓燕. 3D打印在航空航天领域的六大切入点.世界制造技术与装备市场, 2018(1): 68 doi: 10.3969/j.issn.1015-4809.2018.01.012 [10] Ragelle H, Tibbitt M W, Wu S Y, et al. Surface tension-assisted additive manufacturing. Nat Commun, 2018, 9: 1184. doi: 10.1038/s41467-018-03391-w [11] Deng L, Wang S H, Wang P, et al. Selective laser melting of a Ti-based bulk metallic glass. Mater Lett, 2018, 212: 346. [12] Li R D, Shi Y S, Wang Z G, et al. Densification behavior of gas and water atomized 316L stainless steel powder during selective laser melting. Appl Surf Sci, 2010, 256(13): 4350. [13] Cherry J A, Davies H M, Mehmood S, et al. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int J Adv Manuf Technol, 2015, 76(5-8): 869. [14] Zhu Y, Zou J, Yang H Y. Wear performance of metal parts fabricated by selective laser melting: a literature review. JZhejiang Univ-Sci A(Appl Phys & Eng), 2018, 19(2): 95. [15] Shipley H, McDonnell D, Culleton M, et al. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: A review. Int J Mach Tools Manuf, 2018, 128: 1. [16] Gorsse S, Hutchinson C, GounéM, et al. Additive manufacturing of metals: a brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys. Sci Technol Adv Mater, 2017, 18(1): 584. [17] Chen A N, Wu J M, Liu K, et al. High-performance ceramic parts with complex shape prepared by selective laser sintering: a review. Adv Appl Ceram, 2018, 117(2): 100. [18] Lewandowski J J, Seifi M. Metal additive manufacturing: A review of mechanical properties. Annu Rev Mater Res, 2016, 46: 151. [19] Yap C Y, Chua C K, Dong Z L, et al. Review of selective laser melting: Materials and applications. Appl Phys Rev, 2015, 2(4): 041101. [20] Sander G, Thomas S, Cruz V, et al. On the corrosion and metastable pitting characteristics of 316L stainless steel produced by selective laser melting. J Electrochem Soc, 2017, 164(6): C250. [21] Frazier W E. Metal additive manufacturing: a review. JMater Eng Perform, 2014, 23(6): 1917. [22] Prashanth K G, Scudino S, Maity T, et al. Is the energy density a reliable parameter for materials synthesis by selective laser melting? Mater Res Lett, 2017, 5(6): 386. [23] Han J, Yang J J, Yu H C, et al. Microstructure and mechanical property of selective laser melted Ti6Al4Vdependence on laser energy density. Rapid Prototyping J, 2017, 23(2): 217. [24] Chen J, Yang H O, Tang H P, et al. Influence of oxygen content in controlled atmosphere on the processing characteristics of laser rapid forming of TC4 titanium alloy. Rare Met Lett, 2004, 23(3): 23 https://www.cnki.com.cn/Article/CJFDTOTAL-XJKB200403005.htm陈静, 杨海欧, 汤慧萍, 等.成形气氛中氧含量对TC4钛合金激光快速成形工艺的影响.稀有金属快报, 2004, 23(3): 23 https://www.cnki.com.cn/Article/CJFDTOTAL-XJKB200403005.htm [25] Liu F C, Lin X, Yang G L, et al. Microstructures and mechanical properties of laser solid formed nickle base superalloy Inconel 718 prepared in different atmospheres. Acta Metall Sin, 2010, 46(9): 1047 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201009006.htm刘奋成, 林鑫, 杨高林, 等.不同气氛激光立体成形镍基高温合金Inconel 718的显微组织和力学性能.金属学报, 2010, 46(9): 1047 https://www.cnki.com.cn/Article/CJFDTOTAL-JSXB201009006.htm [26] Martin J H, Yahata B D, Hundley J M, et al. 3D printing of high-strength aluminium alloys. Nature, 2017, 549: 365. [27] AlMangour B, Grzesiak D, Yang J M. Scanning strategies for texture and anisotropy tailoring during selective laser melting of TiC/316L stainless steel nanocomposites. JAlloys Compd, 2017, 728: 424. [28] AlMangour B, Grzesiak D, Yang J M. Selective laser melting of TiC reinforced 316L stainless steel matrix nanocomposites: Influence of starting TiC particle size and volume content. Mater Des, 2016, 104: 141. [29] AlMangour B, Grzesiak D, Yang J M. Rapid fabrication of bulk-form TiB2/316L stainless steel nanocomposites with novel reinforcement architecture and improved performance by selective laser melting. J Alloys Compd, 2016, 680: 480. [30] AlMangour B, Grzesiak D, Yang J M. In-situ formation of TiC-particle-reinforced stainless steel matrix nanocomposites during ball milling: Feedstock powder preparation for selective laser melting at various energy densities. Powder Technol, 2018, 326: 467. [31] Lou X Y, Song M, Emigh P W, et al. On the stress corrosion crack growth behaviour in high temperature water of 316L stainless steel made by laser powder bed fusion additive manufacturing. Corros Sci, 2017, 128: 140. [32] Yusuf S M, Nie M Y, Chen Y, et al. Microstructure and corrosion performance of 316L stainless steel fabricated by selective laser melting and processed through high-pressure torsion. J Alloys Compd, 2018, 763: 360. -

下载:

下载: