Effect of addition contents of CaO–Al2O3–SiO2 composite sintering aids on the properties of ZrO2/Al2O3 composite ceramics

-

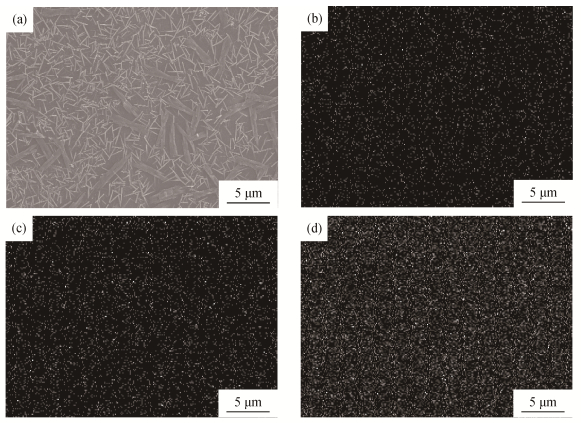

摘要: 以Al(NO3)3·9H2O、Ca(NO)2·4H2O、C8H20O4Si为原料, 采用高分子网络法制备出成分均匀、粒度分布为3~7μm、高活性的CaO–Al2O3–SiO2复合烧结助剂; 将质量分数为3%、5%、7%、9%的CaO–Al2O3–SiO2复合烧结助剂添加到Al2O3和ZrO2原料粉体中, 经干压成型, 在1450℃烧结温度、保温4h的工艺条件下进行常压烧结制备得到ZrO2/Al2O3复相陶瓷试样, 研究烧结助剂添加量对复相陶瓷力学性能和显微组织结构的影响。结果表明:当添加质量分数为5%的CaO–Al2O3–SiO2复合烧结助剂时, ZrO2/Al2O3复相陶瓷的综合性能最达到佳, 相对密度为94%, 显微维氏硬度为1204 MPa, 抗弯强度为321 MPa, 断裂韧性为4.52 MPa·m1/2。Abstract: The CaO–Al2O3–SiO2 composite sintering aids were prepared by polymer network method using Al(NO3)3·9H2O, Ca (NO) 2·4 H2O, and C8H20O4Si as the raw materials, showing the uniform constituent and high activity in the particle sizes of 3~7 μm.The Al2O3 and ZrO2 raw powders were mixed and dry pressed with the CaO–Al2O3–SiO2 composite sintering aids in the mass fraction of 3%, 5%, 7%, and 9%, and then the ZrO2/Al2O3 composite ceramics samples were pressureless sintered at 1450 ℃ for 4 h.The effect of addition contents of CaO–Al2O3–SiO2 composite sintering aids on the mechanical properties and microstructures of ZrO2/Al2O3 composite ceramics were studied.The results show that, the comprehensive properties of ZrO2/Al2O3 composite ceramics added with the CaO–Al2O3–SiO2 composite sintering aids in the mass fraction of 5% are the optimal as the relative density of 94%, the micro-Vickers hardness of 1204 MPa, the flexural strength of 321 MPa, and the fracture toughness of 4.52 MPa·m1/2.

-

表 1 不同陈化时间对凝胶前驱体的影响实验设计方案

Table 1. Experimental design of aging time effect on gel precursor

实验编号 水含量/ mL 陈化时间/ h 丙烯酰胺与N, N-亚甲基双丙烯酰胺质量比 过硫酸铵/ g 1 150 12 6:1 0.1 2 150 24 6:1 0.1 3 150 36 6:1 0.1 表 2 ZrO2/Al2O3复相陶瓷原料成分

Table 2. Composition of raw materials for ZrO2/Al2O3 composite ceramics

编号 α–Al2O3 / g ZrO2 / g CaO–Al2O3–SiO2 / g 试样1 87.00 15.00 3 试样2 82.65 14.25 5 试样3 80.91 13.95 7 试样4 79.17 13.65 9 -

[1] La P Q, Zhang X P, Lu X F. Research status of nanocomposite ceramics fabrication techniques. Mater Rev, 2009, 23(4): 25 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB200907010.htm喇培清, 张秀萍, 卢学峰.纳米复相陶瓷制备技术的研究现状.材料导报, 2009, 23(4): 25 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB200907010.htm [2] Liu G X, Li K Z, Li G B. Effects of ZrO2 additive amount on properties of ZrO2/Al2O3 composite ceramics. Ordn Mater Sci Eng, 2015, 38(4): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG201504012.htm刘国玺, 李克智, 李国斌. ZrO2添加量对Al2O3/ZrO2复相陶瓷性能的影响.兵器材料科学与工程, 2015, 38(4): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG201504012.htm [3] Zhao Z M, Wang J J, Zhang L, et al. Self-propagating high-temperature synthesis of nano/micron Al2O3/ZrO2liner composite ceramics. Powder Metall Technol, 2004, 22(4): 218 doi: 10.3321/j.issn:1001-3784.2004.04.006赵忠民, 王建江, 张龙, 等.纳米/微米Al2O3/ZrO2内衬复相陶瓷的自蔓延高温合成.粉末冶金技术, 2004, 22(4): 218 doi: 10.3321/j.issn:1001-3784.2004.04.006 [4] Wang B J, Wang X M, La P Q. Effects of sintering temperature on mechanical properties and microstructure of 20%ZrO2(3Y)/Al2O3 composite ceramics. J Mater Eng, 2015, 43(10): 66 doi: 10.11868/j.issn.1001-4381.2015.10.011王丙军, 王晓民, 喇培清.烧结温对20%ZrO2(3Y)/Al2O3复相陶瓷力学性能和微观结构的影响.材料工程, 2015, 43(10): 66 doi: 10.11868/j.issn.1001-4381.2015.10.011 [5] Han X L, Liang Z Z, Feng L, et al. Co-precipitated synthesis of A12O3-ZrO2 composite ceramic nanopowders by precipitant and drying method regulation: A systematic study. Ceram Int, 2015, 41: 505. doi: 10.1016/j.ceramint.2014.08.098 [6] Zhao R, Sun H W, Liu H J, et al. Effect of composite sintering additives on A12O3-ZrO2 ceramics relative density. Bull Chin Ceram Soc, 2011, 30(2): 291 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201102007.htm赵冉, 孙洪巍, 刘慧娟, 等.复合烧结助剂对Al2O3-ZrO2陶瓷相对密度的影响.硅酸盐通报, 2011, 30(2): 291 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201102007.htm [7] Ning F, Fu L H, Deng P, et al. Effects of SiO2-B2O3-A12O3 scaling powder on microstructures and properties of Cu-C-SnO2 porous materials sintered by powders. Powder Metall Technol, 2018, 36(5): 335 doi: 10.19591/j.cnki.cn11-1974/tf.2018.05.003倪锋, 傅丽华, 邓攀, 等. SiO2-B2O3-Al2O3助焊剂对粉末烧结Cu-C-SnO2多孔材料组织与性能的影响.粉末冶金技术, 2018, 36(5): 335 doi: 10.19591/j.cnki.cn11-1974/tf.2018.05.003 [8] Hu J L, Liu X, Ding C Z, et al. Influence of additives on properties of low temperature sintering 95 Alumina ceramics. China Ceram, 2012, 48(2): 11 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGTC201202003.htm胡继林, 刘鑫, 丁常泽, 等.添加剂对低温烧结95氧化铝陶瓷性能的影响.中国陶瓷, 2012, 48(2): 11 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGTC201202003.htm [9] Hirota K, Shibaya K, Matsuda H, et al. Fabrication of novel ZrO2(Y2O3)-Al2O3 ceramics having high strength and toughness utilising pulsed electric current pressure sintering(PECPS). Adv Appl Ceram, 2014, 113(2): 73. doi: 10.1179/1743676113Y.0000000107 [10] Ren H L, Long B, Ning J G, et al. Mechanical properties and toughening mechanisms of ZrO2 toughened Al2O3ceramics. Acta Mater Compos Sin, 2015, 32(3): 776 https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201503021.htm任会兰, 龙波, 宁建国, 等. ZrO2增韧Al2O3陶瓷的力学性能和增韧机制.复合材料学报, 2015, 32(3): 776 https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201503021.htm [11] Li J S, Zhang C R, Li B. Advances in precursors for the preparation of boron nitride. Bull Chin Ceram Soc, 2011, 30(3): 567 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201103019.htm李俊生, 张长瑞, 李斌.氮化硼陶瓷先驱体研究进展.硅酸盐通报, 2011, 30(3): 567 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201103019.htm [12] Liu H, Zhang N, Zhang T W, et al. Research progress of boron nitride ceramic composite material produced by hot pressing. Powder Metall Technol, 2014, 24(6): 48 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201406019.htm刘欢, 张宁, 张天文, 等.热压烧结制备BN陶瓷复合材料的研究进展.粉末冶金技术, 2014, 24(6): 48 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201406019.htm [13] Yang F Y. The Study of BN‒SiC Amorphous Ceramic Powder Preparation[Dissertation]. Shenyang: Shenyang University, 2014杨非易. BN‒SiC非晶态陶瓷粉体的制备研究, 沈阳: 沈阳大学, 2014 [14] Zhao J N, Zhang N, Zhou B B, et al. Toughening research and prospect of development on alumina matrix ceramic material. Bull Chin Ceram Soc, 2016, 35(9): 2866 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201609029.htm赵介南, 张宁, 周彬彬, 等. Al2O3基陶瓷材料的增韧研究进展.硅酸盐通报, 2016, 35(9): 2866 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201609029.htm [15] Zhu T B, Xie Z P, Han Y, et al. A novel approach to improve flexural strength of Al2O3-20wt%ZrO2composites by oscillatory pressure sintering. J Am Ceram Soc, 2018, 101: 1397. [16] Li C, Wu M, Zhao J L, et al. Research progress on sintering technology of nano-ceramic material. Hot Working Technol, 2012, 41(24): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201224017.htm李翀, 武明, 赵金龙, 等.纳米陶瓷材料烧结技术的研究进展.热加工工艺, 2012, 41(24): 57 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201224017.htm [17] Zheng Y T, Li H B, Zhou T, et al. Microstructure and mechanical properties of A12O3/ZrO2 eutectic ceramic composites prepared by explosion synthesis. J Alloys Compd, 2013, 551: 475. -

下载:

下载: