Effects of Cr2AlC content on friction and wear properties of copper matrix composites

-

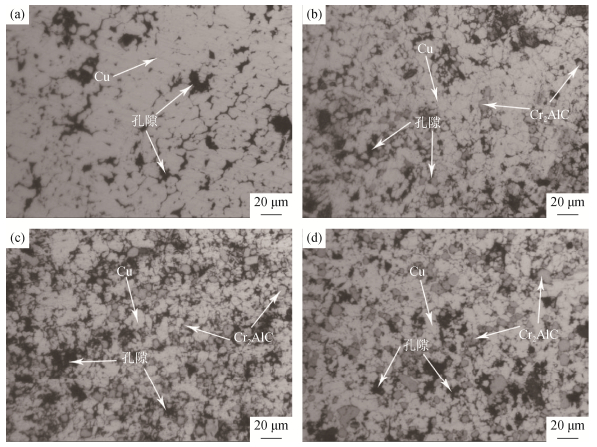

摘要: 采用冷压-烧结方法制备了含质量分数0%、5%、10%、15%Cr2AlC的铜基复合材料, 利用光学显微镜、扫描电子显微镜及能谱仪观察并分析复合材料微观组织和微区成分, 使用HVS-1000型显微硬度计和M-2000型摩擦磨损试验机测试复合材料的硬度和摩擦磨损性能, 分析Cr2AlC质量分数对复合材料硬度、摩擦性能和磨损机理的影响。结果表明:含Cr2AlC铜基复合材料的相对密度为0.8, Cr2AlC均匀分布在铜基体上, 有效提高了复合材料的硬度; 随Cr2AlC质量分数增加, 复合材料摩擦系数先升高后降低, 磨损量先降低后回升, 当Cr2AlC质量分数为10%时, 复合材料的摩擦系数最大, 磨损量最低, 耐磨性能最佳; 未添加Cr2AlC的纯铜材料磨损机理以黏滑为主, 含Cr2AlC铜基复合材料的磨损机理是犁削磨损、剥层磨损和氧化磨损三者的结合。Abstract: The copper matrix composites with Cr2AlC in the mass fraction of 0%, 5%, 10%, and 15% were prepared by cold pressing-sintering method.The microstructures and compositions of the composites were studied by optical microscope (OM), scanning electron microscope (SEM), and energy disperse spectroscope (EDS).The hardness and the properties of friction and wear of the composites were tested on HVS-1000 microhardness tester and M-2000 friction and wear tester.The effects of Cr2AlC contents by mass on the hardness, friction property, and wear mechanism of the composites were analyzed.The results show that, the relative density of copper matrix composites with Cr2AlC is 0.8, the Cr2AlC evenly distributes on the copper matrix and effectively improves the composites hardness.With the increase of Cr2AlC content, the friction coefficient of the composites increases first and then decreases, and the abrasion loss decreases first and then increases.When Cr2AlC content by mass is 10%, the friction coefficient is the largest, the wear rate is the lowest, and the wear resistance is the best.The wear mechanism of pure copper without Cr2AlC is mainly stick slip, and the wear form of copper matrix composites with Cr2AlC is the combination of plough wear, stripping wear, and oxidation wear.

-

Key words:

- copper matrix composites /

- hardness /

- friction /

- wear /

- friction coefficient

-

表 1 复合材料的密度

Table 1. Density of the Cu–Cr2AlC composites

Cr2AlC质量分数/ % 理论密度/ (g·cm-3) 实测密度/ (g·cm-3) 相对密度 0 8.96 7.20 0.804 5 8.65 6.89 0.796 10 8.36 6.67 0.798 15 8.09 6.48 0.801 -

[1] Kelhar L, FerčičJ, Maček-Kržmanc M, et al. The role of Fe and Cu additions on the structural, thermal and magnetic properties of amorphous Al-Ce-Fe-Cu alloys. JNon-Cryst Solids, 2018, 483: 70. doi: 10.1016/j.jnoncrysol.2018.01.003 [2] Rabiee M, Mirzadeh H, Ataie A. Processing of Cu-Fe and Cu-Fe-SiC nanocomposites by mechanical alloying. Adv Powder Technol, 2017, 28(8): 1882. doi: 10.1016/j.apt.2017.04.023 [3] BayramÜ, MaraşlıN. Thermal conductivity and electrical resistivity dependences on growth rate in the directionally solidified Al-Cu-Ni eutectic alloy. J Alloys Compd, 2018, 753: 695. doi: 10.1016/j.jallcom.2018.04.277 [4] Xu X X, Li W B, Wang Y, et al. Study of the preparation of Cu-TiC composites by reaction of soluble Ti and ball-milled carbon coating TiC. Results Phys, 2018, 9: 486. doi: 10.1016/j.rinp.2018.02.059 [5] Cabezas-Villa J L, Olmos L, Vergara-Hernández H J, et al. Constrained sintering and wear properties of Cu-WCcomposite coatings. Trans Nonferrous Met Soc China, 2017, 27(10): 2214. doi: 10.1016/S1003-6326(17)60247-4 [6] Wang Y R, Gao Y M, Li Y F, et al. Research on nickel modified graphite/Cu composites interface. Surf Coat Technol, 2017, 328: 70. doi: 10.1016/j.surfcoat.2017.08.036 [7] Han C S, Guo T M, Nan X L, et al. New research progress in Cu-based composites. Mater Rev, 2012, 26(19): 90 doi: 10.3969/j.issn.1005-023X.2012.19.021韩昌松, 郭铁明, 南雪丽, 等.铜基复合材料的研究新进展.材料导报, 2012, 26(19): 90 doi: 10.3969/j.issn.1005-023X.2012.19.021 [8] Tang G M. Preparation and Properties of Ti2AlN/Cu Composites[Dissertation]. Qinhuangdao: Yanshan University, 2011唐公民. Ti2AlN/Cu复合材料的制备及其性能研究, 秦皇岛: 燕山大学, 2011 [9] Hu M, Zhang Y L, Tang L L, et al. Surface modifying of SiC particles and performance analysis of SiCp/Cu composites. Appl Surf Sci, 2015, 332: 720. doi: 10.1016/j.apsusc.2015.01.130 [10] Zhang C Y, Liu Y W, Yang Z M, et al. Cathode spot movement on a continuous carbon fiber reinforced Cu matrix composite in vacuum. Vacuum, 2013, 93: 45. doi: 10.1016/j.vacuum.2013.01.004 [11] Jiang Y H, Wang C, Liang S H, et al. TiB2(-TiB)/Cu in-situ composites prepared by hot-press with the sintering temperature just beneath the melting point of copper. Mater Charact, 2016, 121: 76. doi: 10.1016/j.matchar.2016.09.038 [12] Gao L Q, Zhou Y, Zhai H X, et al. Research status and progress of Mn+1AXn/Cu composites. Mater Rev, 2006, 20(Suppl 2): 397 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2006S2116.htm高立强, 周洋, 翟洪祥, 等. Mn+1AXn三元层状陶瓷增强铜基复合材料的研究进展.材料导报, 2006, 20(增刊2): 397 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2006S2116.htm [13] Zhang L Q, Li S B, Chen X D, et al. Abnormal thermal shock behavior in electrical conductivity of Ti2SnC. Prog Nat Sci Mater Int, 2017, 27(4): 527. doi: 10.1016/j.pnsc.2017.06.008 [14] Cao J, Yin Z W, Li H L, et al. Tribological and mechanical properties of Ti2AlC coating at room temperature and800℃. Ceram Int, 2018, 44(1): 1046. doi: 10.1016/j.ceramint.2017.10.045 [15] Ying G B. In-situ Synthesis Mechanism and Properties of Cr2AlC, Ti2AlC Ceramics and Their Composites[Dissertation]. Harbin: Harbin Institute of Technology, 2011应国兵. Cr2AlC、Ti2AlC陶瓷及其复合材料的原位合成机理与性能的研究, 哈尔滨: 哈尔滨工业大学, 2011 [16] Zeng J L, Hai W X, Yao R Q, et al. Tribological characteristics of Ti3SiC2/Cu tribo-pairs in sliding electrical contact. Tribology, 2015, 35(1): 102 https://www.cnki.com.cn/Article/CJFDTOTAL-MCXX201501017.htm曾俊菱, 海万秀, 姚瑞清, 等. Ti3SiC2/Cu摩擦副的载流摩擦学性能.摩擦学学报, 2015, 35(1): 102 https://www.cnki.com.cn/Article/CJFDTOTAL-MCXX201501017.htm [17] Wu J Y, Zhou Y C, Wang J Y. Tribological behavior of Ti2SnC particulate reinforced copper matrix composites. Mater Sci Eng A, 2006, 422: 266. doi: 10.1016/j.msea.2006.02.010 [18] Wang S. Preparation and Characterization of Ti2AlC/Cu Composites and Research of Its Friction and Wear Behavior[Dissertation]. Harbin: Harbin Institute of Technology, 2014王帅. Ti2AlC/Cu复合材料的制备表征及其摩擦磨损行为研究, 哈尔滨: 哈尔滨工业大学, 2014 [19] Wei X M. Fabrication and Tribological Properties of Ti3AlC2/Cu Co-continuous Composites[Dissertation]. Beijing: Beijing Jiaotong University, 2016位兴民.双连续相Ti3AlC2/Cu复合材料的制备及摩擦学性能研究, 北京: 北京交通大学, 2016 [20] Lu L. Study on Tribological Behaviors of Cu-Ti3SiC2Composites and Preparation of Porous Ti3SiC2[Dissertation]. Guangzhou: South China University of Technology, 2014禄璐. Cu-Ti3SiC2复合材料的摩擦磨损性能及多孔Ti3SiC2的制备, 广州: 华南理工大学, 2014 [21] Li Y M, Zhao G R, Qian Y H, et al. Deposition of phase-pure Cr2AlC coating by DC magnetron sputtering and post annealing using Cr-Al-C targets with controlled elemental composition but different phase compositions. JMater Sci Technol, 2018, 34: 466. http://www.sciencedirect.com/science/article/pii/S1005030217300403 [22] Smialek J L, Nesbitt J A, Gabb T P, et al. Hot corrosion and low cycle fatigue of a Cr2AlC-coated superalloy. Mater Sci Eng A, 2018, 711: 119. doi: 10.1016/j.msea.2017.10.098 [23] Walter C, Sigumonrong D P, El-Raghy T, et al. Towards large area deposition of Cr2AlC on steel. Thin Solid Films, 2006, 515(2): 389. doi: 10.1016/j.tsf.2005.12.219 [24] Lei Y, Liu J Y, Wang M, et al. Preparation and mechanical properties of Cr2AlC particulate reinforced Cu matrix composites. Powder Metall Technol, 2013, 31(5): 340 doi: 10.3969/j.issn.1001-3784.2013.05.004雷宇, 刘锦云, 王敏, 等. Cr2AlC颗粒增强Cu基复合材料的制备及力学性能研究.粉末冶金技术, 2013, 31(5): 340 doi: 10.3969/j.issn.1001-3784.2013.05.004 [25] Wang X S, Lu Z L, Lin G T, et al. Effect of Cr2AlC content on the properties of a Cu-Cr2AlC composite. Results Phys, 2016, 6: 789. doi: 10.1016/j.rinp.2016.09.020 [26] Sun L, Guo Y, Liu J Y, et al. The technology research of the Cu-15%Cr2AlC composite prepared by cold-pressing sintering method. Powder Metall Technol, 2015, 33(5): 359 doi: 10.3969/j.issn.1001-3784.2015.05.009孙林, 郭阳, 刘锦云, 等.冷压烧结法制备Cu-15%Cr2AlC复合材料工艺研究.粉末冶金技术, 2015, 33(5): 359 doi: 10.3969/j.issn.1001-3784.2015.05.009 [27] Zeng S, Su Z L, Zhou J. Fabrication and mechanical properties of Cu-Cr2AlC composites. J Xiamen Univ Nat Sci, 2014, 53(5): 739 https://www.cnki.com.cn/Article/CJFDTOTAL-XDZK201405019.htm曾舒, 苏忠亮, 周健. Cr2AlC颗粒增强Cu基复合材料的制备与性能表征.厦门大学学报(自然科学版), 2014, 53(5): 739 https://www.cnki.com.cn/Article/CJFDTOTAL-XDZK201405019.htm [28] Kong Y R, Guo Q, Zhang D. Review on the interfacial properties of particle-reinforced aluminum matrix composites. Mater Rev, 2015, 29(5): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201509005.htm孔亚茹, 郭强, 张荻.颗粒增强铝基复合材料界面性能的研究.材料导报, 2015, 29(5): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201509005.htm [29] Yao G X, Niu H W. Effects of nickel on tribological wear properties of copper-based powder metallurgy friction materials. Hot Working Technol, 2016, 45(8): 121 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201608034.htm姚冠新, 牛华伟.镍对铜基粉末冶金摩擦材料摩擦磨损性能的影响.热加工工艺, 2016, 45(8): 121 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201608034.htm [30] Wang T G, Liang Q C, Qin Q. Effect of Al2O3 content on friction and wear properties of copper-base powder metallurgy friction materials. Powder Metall Ind, 2016, 26(1): 46 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201601012.htm王天国, 梁启超, 覃群. Al2O3含量对铜基粉末冶金摩擦材料摩擦磨损性能的影响.粉末冶金工业, 2016, 26(1): 46 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201601012.htm [31] Qin Q, Wang T G, Hua J J. Effect of B4C content on friction and wear properties of copper-based powder metallurgy friction materials. Lubr Eng, 2017, 42(8): 77 doi: 10.3969/j.issn.0254-0150.2017.08.014覃群, 王天国, 华建杰. B4C含量对铜基粉末冶金摩擦材料摩擦磨损性能的影响.润滑与密封, 2017, 42(8): 77 doi: 10.3969/j.issn.0254-0150.2017.08.014 [32] Zhan Y Z, Zhang G D. Tribological behavior of SiCparticle reinforced copper matrix composites. Tribology, 2003, 23(6): 495 doi: 10.3321/j.issn:1004-0595.2003.06.009湛永钟, 张国定. SiCp/Cu复合材料摩擦磨损行为研究.摩擦学学报, 2003, 23(6): 495 doi: 10.3321/j.issn:1004-0595.2003.06.009 [33] Zhou H B, Yao P P, Xiao Y L, et al. Topographical characteristics and wear mechanism of copper-based powder metallurgy friction materials reinforced by SiCparticle. Chin J Nonferrous Met, 2014, 24(9): 2272 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201409011.htm周海滨, 姚萍屏, 肖叶龙, 等. SiC颗粒强化铜基粉末冶金摩擦材料的表面形貌特征及磨损机理.中国有色金属学报, 2014, 24(9): 2272 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201409011.htm -

下载:

下载: