Effect of long-term aging on γ' phase and lattice constant of FGH95 P/M Ni-based superalloy

-

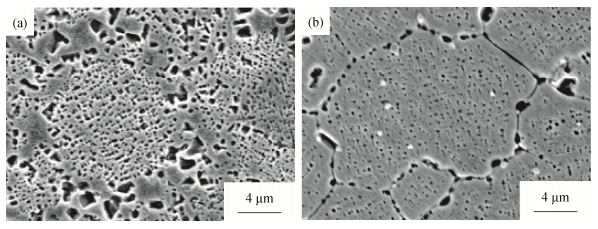

摘要: 在不同温度下对FGH95镍基粉末高温合金进行长期时效处理,通过合金显微组织观察和X射线衍射分析,研究了长期时效对FGH95合金γ'相及晶格常数的影响。结果表明,完全热处理FGH95合金经450和550℃长期时效后,合金中细小γ'相略有长大,其粗化行为符合Lifshitz,Slyozov和Wagner(LWS)粗化动力学理论;随着时效时间的延长,FGH95合金中γ'相的晶格常数有所增加,而γ和γ'两相的晶格错配度减小;与时效时间相比,时效温度对FGH95合金中γ'相尺寸及晶格常数的影响更大。Abstract: The effect of long-term aging on the γ' phase and lattice constant of FGH95 P/M Ni-based superalloy was investigated by microstructures observation and X-ray diffraction analysis. The results show that, after long-term aging at 450 and 550, th℃ e fine γ' phases in the full heat-treated FGH95 alloys are slightly grown up, in accordance with the coarsening kinetics in Lifshitz, Slyozov, and Wagner (LWS) theory. With the extension of aging time, the lattice constants of γ' phase in FGH95 alloys increase, while the lattice mismatches of the γ and γ' two phases decrease. Compared with the aging time, the aging temperature has a greater influence on the γ' phase size and lattice constant of the FGH95 alloy.

-

Key words:

- P/M Ni-based superalloy /

- long-term aging /

- γ'phase /

- lattice constant

-

表 1 FGH95镍基粉末高温合金化学成分(质量分数)

Table 1. Chemical composition of FGH95 P/M Ni-based superalloy

% C B Cr Co Al Ti W Mo Nb Ni 0.060 0.012 12.980 8.000 3.480 2.550 3.400 3.400 3.500 余量 -

[1] Shu D L, Tian S G, Tian N, et al. Thermodynamic analysis of carbide precipitation and effect of its configuration on creep properties of FGH95 powder nickel-based superalloy. Mater Sci Eng A, 2017, 700:152 doi: 10.1016/j.msea.2017.05.108 [2] Ning Y Q, Yao Z K, Li H, et al. High temperature deformation behavior of hot isostatically pressed P/M FGH4096 superalloy. Mater Sci Eng A, 2010, 527:961 doi: 10.1016/j.msea.2009.09.011 [3] Tao Y, Jia J, Liu J T. Microstructure characterization and mechanical properties of FGH95 turbine blade retainers. J Iron Steel Res Int, 2010, 17(9):73 doi: 10.1016/S1006-706X(10)60146-X [4] Xie J, Tian S G, Zhou X M, et al. Influence of heat treatment regimes on microstructure and creep properties of FGH95 nickel base superalloy. Mater Sci Eng A, 2012, 538:306 doi: 10.1016/j.msea.2012.01.049 [5] Tian S G, Xie J, Zhou X M, et al. Microstructure and creep behavior of FGH95 nickel-base superalloy. Mater Sci Eng A, 2011, 528:2076 doi: 10.1016/j.msea.2010.11.038 [6] Tian S G, Li J J, Zhou X M, et al. Constituting and distribution feature of phases in FGH95 nickle base superalloy. Rare Met, 2011, 30(Suppl 1):457 http://cpfd.cnki.com.cn/Article/CPFDTOTAL-XYJS201009001099.htm [7] Luo L, Ma Y, Li S S, et al. Evolutions of microstructure and lattice misfit in a γ'-rich Ni-based superalloy during ultra-high temperature thermal cycle. Intermetallics, 2018, 99:18 doi: 10.1016/j.intermet.2018.05.011 [8] Jiang X, Yin H Q, Zhang C, et al. An materials informatics approach to Ni-based single crystal superalloys lattice misfit prediction. Comput Mater Sci, 2018, 143:295 doi: 10.1016/j.commatsci.2017.09.061 [9] Arora K, Kishida K, Tanaka K, et al. Effects of lattice misfit on plastic deformation behavior of single-crystalline micropillars of Ni-based superalloys. Acta Mater, 2017, 138:119 doi: 10.1016/j.actamat.2017.07.044 [10] Xie J, Tian S G, Zhou X M. Effects of HIP temperature on microstructure and lattice constant of FGH95 superalloy. Trans Mater Heat Treat, 2011, 32(11):59 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201111015.htm谢君, 田素贵, 周晓明.热等静压温度对FGH95合金组织形貌及点阵常数的影响.材料热处理学报, 2011, 32(11):59 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201111015.htm [11] Coakley J, Lass E A, Ma D, et al. Lattice parameter misfit evolution during creep of a cobalt-based superalloy single crystal with cuboidal and rafted gamma-prime microstructures. Acta Mater, 2017, 136:118 doi: 10.1016/j.actamat.2017.06.025 [12] Jia J, Tao Y, Zhang Y W, et al. Reverse coarsening splitting behavior of the secondary γ'in superalloy FGH95 during long-term aging. Rare Met Mater Eng, 2012, 41(7):1156 doi: 10.3969/j.issn.1002-185X.2012.07.007贾建, 陶宇, 张义文, 等. FGH95合金长期时效过程中二次γ'相的"反粗化"分裂行为.稀有金属材料与工程, 2012, 41(7):1156 doi: 10.3969/j.issn.1002-185X.2012.07.007 [13] Ma G J, Wang X Q, Luo X J. Microstruture stability of alloy FGH95 during long time aging. J Iron Steel Res, 2011, 23(Suppl 2):462 https://www.cnki.com.cn/Article/CJFDTOTAL-IRON2011S2121.htm马国君, 王旭青, 罗学军. FGH95粉末高温合金长期时效组织稳定性研究.钢铁研究学报, 2011, 23(增刊2):462 https://www.cnki.com.cn/Article/CJFDTOTAL-IRON2011S2121.htm [14] Zhang L N, Wang P, Dong J X, et al. Influence of long-term aging treatment on γ' phase evolution in FGH97 P/M alloy. Trans Mater Heat Treat, 2012, 33(12):30张丽娜, 王璞, 董建新, 等.长期时效对FGH97合金γ'相演化的影响.材料热处理学报, 2012, 33(12):30 [15] Fan X Q, Guo Z P, Wang X F, et al. Morphology evolution of γ'precipitates in a powder metallurgy Ni-base superalloy. Mater Charact, 2018, 139:382 doi: 10.1016/j.matchar.2018.02.038 [16] Zhao P Y, Shen C, Niezgoda S R, et al. Heterogeneous γ'microstructures in nickel-base superalloys and their influence on tensile and creep performance. Int J Plast, 2018, 109:153 doi: 10.1016/j.ijplas.2018.06.002 [17] Xie J, Tian S G, Zhou X M, et al. Influence of solution temperature on microstructure and creep behaviors of powder nickel-based superalloy. Powder Metall Technol, 2011, 29(4):263 http://pmt.ustb.edu.cn/article/id/fmyjjs201104005谢君, 田素贵, 周晓明, 等.固溶温度对粉末镍基高温合金组织与蠕变行为的影响.粉末冶金技术, 2011, 29(4):263 http://pmt.ustb.edu.cn/article/id/fmyjjs201104005 [18] Yue X D, Li J R, Shi Z X, et al. Designing of homogenization-solution heat treatment for advanced single crystal superalloys. Rare Met Mater Eng, 2017, 46(6):1530 doi: 10.1016/S1875-5372(17)30159-5 [19] Baldan A. Progress in Ostwald ripening theories and their applications to the γ'-precipitates in nickel-base superalloys:Part II Nickel-base superalloys. J Mater Sci, 2002, 37(12):2379 doi: 10.1023/A:1015408116016 [20] Li H Y, Zuo L L, Song X P, et al. Coarsening behavior of γ'particles in a nickel-base superalloy. Rare Met, 2009, 28(2):197 doi: 10.1007/s12598-009-0039-x -

下载:

下载: