In-situ synthesized TiC particle-reinforced titanium matrix composites prepared by gas-solid reaction

-

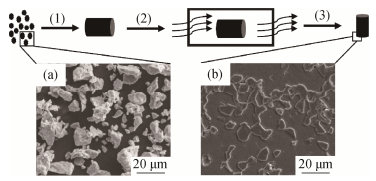

摘要: 以氢化脱氢钛粉为原料, 经冷等静压成型, 在一定温度下通过CH4和钛粉颗粒间的气固反应在钛粉表面原位生成均匀的TiC颗粒, 采用真空烧结技术制备得到氧含量(体积分数)低于0.2%的TiC颗粒增强钛基复合材料。研究表明, TiC颗粒体积分数比可通过气固反应温度和时间控制, 可获得较高体积分数(> 30%)的TiC颗粒增强钛基复合材料。TiC首先在钛粉颗粒表面形成, 烧结过程中, 钛粉颗粒明显阻碍TiC晶粒长大, 细化TiC晶粒; 同时, 过多的TiC颗粒也阻碍烧结过程中钛的自扩散, 降低烧结相对密度。钛粉压坯在700℃、CH4气氛下发生气固反应(30 min), 再经1300℃烧结后获得的相对密度为98.6%的烧结试样, 试样的综合力学性能较好, 抗拉强度为606 MPa, 延伸率达14.4%, 硬度为HV 442。值得注意的是, 较短时间的气固反应不能够保证压坯内外整体实现原位生成均匀TiC颗粒, 导致烧结试样内外组织的不均性。Abstract: Using hydrogenation-dehydrogenation titanium powders as the raw materials, the in-situ synthesized TiC particles were prepared by gassolid reaction at a certain temperature under the atmosphere of CH4 after cold isostatic pressing, then the TiC particle-reinforced titanium matrix composites were manufactured by vacuum sintering with the oxygen content (volume fraction) less than 0.2%.In the results, the volume fraction of TiC particles can be controlled by adjusting the temperature and time of gassolid reaction, and the TiC particle-reinforced titanium matrix composites with the higher volume fraction of TiC particles (> 30%) can be obtained.TiC is first formed on the surface of titanium powders, and the growth of TiC particles is obviously hindered by Ti powders, resulting in the grain refining of TiC particles; however, the excessive TiC particles also hinder the self-diffusion process of titanium in the sintering process and reduce the relative density.The titanium powder compacts handled by gassolid reaction at 700 ℃ under the atmosphere of CH4 for 30 min are vacuum sintered at 1300 ℃, and the sintered specimens show the better comprehensive mechanical properties, the tensile strength is 606 MPa, the elongation is 14.4%, the hardness is HV 442, and the relative density is 98.6%.However, a relatively short period of gassolid reaction cannot guarantee the uniform distribution of TiC particles, resulting in the inhomogeneity in the internal and external structures of sintered specimens.

-

表 1 TiC颗粒增强钛基复合材料间隙原子成分(质量分数)

Table 1. Contents of interstitial atom by mass in TiC-reinforced titanium matrix composites

% 气固反应温度/ ℃ 含不同体积分数TiC颗粒增强钛基复合材料 间隙原子质量分数/ % N O H 未反应 Ti 0.063 0.15 0.012 600 Ti–2%TiC 0.065 0.17 0.009 700 Ti–7%TiC 0.056 0.20 0.015 800 Ti–16%TiC 0.070 0.24 0.014 900 Ti–32%TiC 0.065 0.28 0.007 表 2 在1300℃下烧结的TiC增强钛基试样的力学性能

Table 2. Mechanical properties of TiC reinforced titanium matrix composites at 1300℃sintering

气固反应温度/ ℃ 含不同体积分数TiC颗粒增强钛基复合材料 硬度, HV 抗拉强度/ MPa 屈服强度/ MPa 延伸率/ % 未反应 Ti 346 538 454 13.2 600 Ti–2%TiC 360 563 466 6.8 700 Ti–7%TiC 442 606 503 14.4 800 Ti–16%TiC 466 648 552 4.3 900 Ti–32%TiC 492 463 — — -

[1] Tjong S C, Ma Z Y. Microstructural and mechanical characteristics of in situ metal matrix composites. Mater Sci Eng R, 2000, 29(s3-4): 49. http://www.sciencedirect.com/science/article/pii/S0927796X00000243 [2] Morsi K, Patel V V. Processing and properties of titanium-titanium boride(TiBw)matrix composites-a review. J Mater Sci, 2007, 42(6): 2037. doi: 10.1007/s10853-006-0776-2 [3] Geng L, Ni D R, Zhang J, et al. Hybrid effect of TiBw and TiCp on tensile properties of in situ titanium matrix composites. J Alloys Compd, 2008, 463(1-2): 488. doi: 10.1016/j.jallcom.2007.09.054 [4] Tang H P, Huang B Y, Liu Y, et al. Progress in powder metallurgy particle reinforced Ti matrix composite. Powder Metall Technol, 2004, 22(5): 293 doi: 10.3321/j.issn:1001-3784.2004.05.008汤慧萍, 黄伯云, 刘咏, 等.粉末冶金颗粒增强钛基复合材料研究进展.粉末冶金技术, 2004, 22(5): 293 doi: 10.3321/j.issn:1001-3784.2004.05.008 [5] Fleck N A, Smith R A. Effect of density on tensile strength, fracture toughness, and fatigue crack propagation behaviour of sintered steel. Powder Metall, 1981, 24(3): 121. doi: 10.1179/pom.1981.24.3.121 [6] Zadra M, Girardini L. High-performance, low-cost titanium metal matrix composites. Mater Sci Eng A, 2014, 608(1): 155. [7] Khurram S, Kingshott P, Wen C. Carbon nanotube reinforced titanium metal matrix composites prepared by powder metallurgy-a review. Crit Rev Solid State Mater Sci, 2015, 40(1): 38. doi: 10.1080/10408436.2014.929521 [8] Sherif El-Eskandarany M. Structure and properties of nanocrystalline TiC full-density bulk alloy consolidated from mechanically reacted powders. J Alloys Compd, 2000, 305(1-2): 225. doi: 10.1016/S0925-8388(00)00692-7 [9] Zheng H, Jaganandham K. Thermal conductivity and interface thermal conductance in composites of titanium with graphene platelets. J Heat Transfer, 2014, 136(6): 061301. doi: 10.1115/1.4026488 [10] Kondoh K, Threrujirapapong T, Imai H, et al. CNTs/TiCreinforced titanium matrix nanocomposites via powder metallurgy and its microstructural and mechanical properties. J Nanomater, 2008, 2008: 127538. http://dl.acm.org/citation.cfm?id=1731639 [11] Xu D, Lu W J, Yang Z F, et al. In situ technique for synthesizing multiple ceramic particulates reinforced titanium matrix composites(TiB+TiC+Y2O3)/Ti. JAlloys Compd, 2005, 400(1): 216. http://www.sciencedirect.com/science/article/pii/S0925838805003579 [12] Xie L C, Jiang C H, Lu W J, et al. Investigation on the residual stress and microstructure of(TiB+TiC)/Ti-6Al-4V composite after shot peening. Mater Sci Eng A, 2011, 528(9): 3423. doi: 10.1016/j.msea.2011.01.022 [13] Yang Y, Yang S L. Research status and development prospect of metal matrix composite reinforced by carbon nano-tubes. Mater Rev, 2007, 21(Suppl 1): 182 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2007S1055.htm杨益, 杨盛良.碳纳米管增强金属基复合材料的研究现状及展望.材料导报, 2007, 21(增刊1): 182 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2007S1055.htm [14] Zhou P, Qin J N, LüW J, et al. Microstructure and mechanical properties of in-situ synthesized titanium matrix composites prepared by powder metallurgy. Powder Metall Ind, 2009, 19(3): 11 doi: 10.3969/j.issn.1006-6543.2009.03.003周鹏, 覃继宁, 吕维洁, 等.粉末冶金制备原位自生钛基复合材料的显微组织和力学性能研究.粉末冶金工业, 2009, 19(3): 11 doi: 10.3969/j.issn.1006-6543.2009.03.003 [15] Qin Q, Wang T G, Fan H X. Progress in Ti matrix composites fabricated by powder metallurgy in situ method, Powder Metall Ind, 2010, 20(5): 42覃群, 王天国, 范宏训.粉末冶金原位合成法制备钛基复合材料的研究进展.粉末冶金工业, 2010, 20(5): 42 [16] Li S, Sun B, Imai H, et al. Powder metallurgy Ti-TiCmetal matrix composites prepared by in situ reactive processing of Ti-VGCFs system. Carbon, 2013, 61: 216. doi: 10.1016/j.carbon.2013.04.088 -

下载:

下载: