Application of SiO2 nanoparticle coating by electrostatic self-assembly on metal fiber felt

-

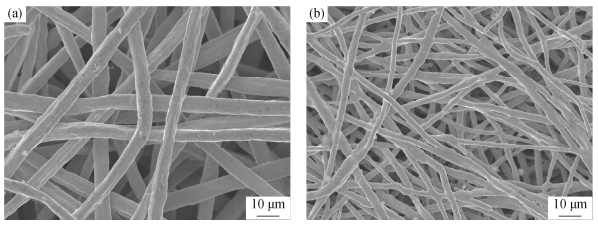

摘要: 采用静电自组装技术将SiO2纳米颗粒均匀涂覆在金属纤维表面, 研究涂覆前后金属纤维毡的过滤精度、透气量、泡点压力、耐磨性及耐蚀性。结果表明, 经过纳米自组装涂覆后, 金属纤维毡具有良好的疏水性和通量匹配, 同时过滤精度、耐腐蚀性和耐磨性也有所提高, 有助于延长金属纤维毡在复杂腐蚀介质中的使用寿命。Abstract: SiO2 nanoparticles were uniformly coated on the surface of metal fibers by electrostatic self-assembly technology.The filter fineness, air-permeability, bubble-point pressure, abrasive resistance, and corrosion resistance of metal fiber felt uncoated and coated SiO2 nanoparticles by electrostatic self-assembly were investigated.The results show that, the metal fiber felt has good hydrophobicity and flux match after being coated SiO2 nanoparticles by electrostatic self-assembly, and the filtration accuracy, corrosion resistance, and abrasion resistance of the metal fiber felt are also improved, prolonging the service life of metal fiber felt in the complex corrosive medium.

-

Key words:

- electrostatic self-assembly technology /

- metal fiber felt /

- nanoparticles /

- coating /

- filtration

-

表 1 涂覆前后纤维毡耐蚀性

Table 1. Corrosion resistance of the uncoated and coated metal fiber felt

样品 腐蚀前/ mg 腐蚀后/ mg 失重率/ % 原始纤维毡 1.339 1.301 2.9 涂覆纤维毡 1.454 1.432 1.5 -

[1] Liu G Q. Application of high-temperature dedusting technique in steelmaking dedusting of electric ARCfurnace. Environ Eng, 2012, 30(6): 82 https://www.cnki.com.cn/Article/CJFDTOTAL-HJGC201206020.htm刘贵琦.高温除尘技术在电弧炉炼钢除尘中的应用.环境工程, 2012, 30(6): 82 https://www.cnki.com.cn/Article/CJFDTOTAL-HJGC201206020.htm [2] Wang T Q. Filtrating characteristics and application of metallic fiber sintered felt. J Filtr Sep, 2003, 13(1): 26 doi: 10.3969/j.issn.1005-8265.2003.01.007王同庆.金属纤维烧结毡过滤材料过滤性能与科学应用.过滤与分离, 2003, 13(1): 26 doi: 10.3969/j.issn.1005-8265.2003.01.007 [3] Hou L Q, Lu W J, Zhuo L, et al. The application of metal fiber felt in high temperature dust removal. Shandong Chem Ind, 2015, 44(22): 176 doi: 10.3969/j.issn.1008-021X.2015.22.069侯力强, 卢文静, 卓磊, 等.金属纤维毡在高温除尘方面的应用.山东化工, 2015, 44(22): 176 doi: 10.3969/j.issn.1008-021X.2015.22.069 [4] Zhuo L, Liu H B, Zhang G P, et al. Research on the metal fiber sintered crunode prepared by different fiber diameter and sintering temperature. New Technol New Process, 2017(8): 15 https://www.cnki.com.cn/Article/CJFDTOTAL-XJXG201708005.htm卓磊, 刘宏斌, 张国鹏, 等.纤维丝径和烧结温度对金属纤维毡烧结结点影响的研究.新技术新工艺, 2017(8): 15 https://www.cnki.com.cn/Article/CJFDTOTAL-XJXG201708005.htm [5] Li B. Study on Corrosion Behavior of Sintered Stainless Steel Fiber Porous Material[Dissertation]. Xi'an: Xi'an University of Architecture and Technology, 2010李彬.烧结不锈钢纤维多孔材料腐蚀行为研究, 西安: 西安建筑科技大学, 2010 [6] Feng P. Investigation on the Sintering Behavior of Porous316L Stainless Steel Fiber Felt[Dissertation]. Changsha: Central South University, 2014冯萍. 316L不锈钢纤维毡烧结行为的研究, 长沙: 中南大学, 2014 [7] Yu L P, Liu X L, Zhang H B, et al. Development of metal and alloy micro-filtration membranes. Mater Sci Eng Powder Metall, 2015, 20(5): 670 doi: 10.3969/j.issn.1673-0224.2015.05.002喻林萍, 刘新利, 张惠斌, 等.金属及金属合金微滤膜的研究进展.粉末冶金材料科学与工程, 2015, 20(5): 670 doi: 10.3969/j.issn.1673-0224.2015.05.002 [8] Fan Y Q, Qi H, Xu N P. Advance in preparation techniques of porous ceramic membranes. CIESC J, 2013, 64(1): 107 doi: 10.3969/j.issn.0438-1157.2013.01.013范益群, 漆虹, 徐南平.多孔陶瓷膜制备技术研究进展.化工学报, 2013, 64(1): 107 doi: 10.3969/j.issn.0438-1157.2013.01.013 [9] Wang F, Xie Z P, Qian F L, et al. Preparation and development of porous ceramic membrane supports. Bull Chin Ceram Soc, 2012, 31(2): 285 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201202013.htm王峰, 谢志鹏, 千粉玲, 等.多孔陶瓷膜支撑体的制备研究进展.硅酸盐通报, 2012, 31(2): 285 https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201202013.htm [10] Qiu Y R. Research on PVA Modified UF Membrane Based on Felt-Metal[Dissertation]. Changsha: Central South University, 2003邱运仁.金属纤维毡PVA表面改性超滤膜的研究, 长沙: 中南大学, 2003 [11] Ma R F, Li T H, Zhuang Q. et al. Synthesis of CS/MWCNTS composites by electrostatic self-assmbley. Carbon Tech, 2009, 28(2): 9 doi: 10.3969/j.issn.1001-3741.2009.02.003马如飞, 李铁虎, 庄强, 等.静电自组装碳纳米管/壳聚糖复合材料.炭素技术, 2009, 28(2): 9 doi: 10.3969/j.issn.1001-3741.2009.02.003 [12] Zhai Q X, Huang Y, Li Y Q, et al. Development of electrostatic self-assembly nano-composite thin films. Dev Appl Mater, 2010, 25(2): 86 doi: 10.3969/j.issn.1003-1545.2010.02.019翟青霞, 黄英, 李玉青, 等.静电自组装膜研究进展.材料开发与应用, 2010, 25(2): 86 doi: 10.3969/j.issn.1003-1545.2010.02.019 [13] Zhou Q, Dong P, Cheng B Y. Three-dimensionally ordered self-assembly of SiO2 colloidal particles. Chemistry, 2004, 67(4): 290 doi: 10.3969/j.issn.0441-3776.2004.04.011周倩, 董鹏, 程丙英. SiO2胶体颗粒的三维有序自组装.化学通报, 2004, 67(4): 290 doi: 10.3969/j.issn.0441-3776.2004.04.011 [14] Zhang Y, Jia Y R, Shao J Z. Electrostatic self-assembly fabrication of SiO2 multilayer films with structural color. Dye Finish, 2012, 38(17): 1 doi: 10.3969/j.issn.1000-4017.2012.17.001张云, 贾彦荣, 邵建中.结构生色SiO2多层膜的静电自组装法构造.印染, 2012, 38(17): 1 doi: 10.3969/j.issn.1000-4017.2012.17.001 [15] Li Z Q, Zhou G F, Chen M L. Determination of gas permeability of porous materials. Powder Metall Technol, 1996, 14(1): 52 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ601.013.htm李忠全, 周桂芬, 陈木兰.多孔材料气体渗透性的测定.粉末冶金技术, 1996, 14(1): 52 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ601.013.htm [16] Shi D, Yang Y A. Knowledge propagation of different fluid permeability of stainless steel fiber felt. Today Massmedia, 2010, 18(10): 179 doi: 10.3969/j.issn.1672-8122.2010.10.085石丹, 杨延安.不锈钢纤维毡不同流体透过性能的知识传播.今传媒, 2010, 18(10): 179 doi: 10.3969/j.issn.1672-8122.2010.10.085 [17] Liu P S, Ma X M. Porous Material Testing Method. Beijing: Metallurgical Industry Press, 2006刘培生, 马晓明.多孔材料检测方法.北京: 冶金工业出版社, 2006 [18] She B Q, Dong L F, Wu Y J, et al. Study on the filtering precision of porous material. J Filtr Sep, 2013, 23(2): 38 doi: 10.3969/j.issn.1005-8265.2013.02.010佘勃强, 董领锋, 吴引江, 等.关于多孔材料过滤精度的探讨.过滤与分离, 2013, 23(2): 38 doi: 10.3969/j.issn.1005-8265.2013.02.010 -

下载:

下载: