Effect of technological parameters on high indium and high tin silver-based brazing filler metal powders by electromagnetic compaction molding

-

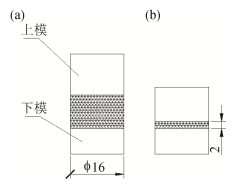

摘要: 根据离散元相关理论, 利用EDEM软件对高铟高锡银基钎料粉末电磁压制过程进行仿真模拟, 探究工艺参数对Ag–Cu–Sn–In系钎料压制过程中的影响规律, 分析钎料粉末的致密化行为, 并研究Sn元素和In元素对钎料粉末相对密度的影响; 在不同电压和电容条件下, 对Ag–19.5Cu–15In–15Sn钎料粉末压制过程进行了仿真模拟, 分析不同放电参数对压坯相对密度的影响; 最后通过压制设备制备钎料压坯, 对仿真结果进行验证。结果表明, 在相同压制力下, In质量分数越高, 获得的压坯相对密度越大; 在电容相同的情况下, 电压越大压坯的相对密度越大, 但增幅逐渐减缓; 在电压相同的情况下, 电容越大压坯的相对密度越大, 但增幅大致不变。实验验证结果表明, 仿真误差小于8%, 钎料电磁压制离散元仿真模型具有一定的参考价值。Abstract: The electromagnetic compaction process of high indium and high tin silver-based brazing filler metal powders was simulated by EDEM software, according to the theory of discrete element, the influences of technological parameters on Ag–Cu–Sn–In series brazing filler metal powders during the compaction process were investigated, the densification behavior of silver-based brazing filler metal powders was analyzed, and the effects of indium and tin on the relative density of compact was studied.The compaction process of Ag–19.5 Cu–15 In–15 Sn solder powders was simulated in different voltages and capacitance; the effects of discharge parameters on the relative density of compact were analyzed.Finally, the simulation was verified by preparing solder compact in the suppression equipment.The results show that, in the same compacting force, the higher the contents of indium by mass are, the higher the relative density of compact is; in the same capacitance, the higher the voltage is, the higher the relative density of compact is, but the amplification gradually slows down; in the same voltage, the higher the capacitance is, the higher the relative density of compact is, and the amplification is roughly constant.The verification results show that, the simulation error is less than 8%, the discrete element simulation model of brazing filler metal electromagnetic compaction has a certain reference value.

-

表 1 实验用原料金属物理性质

Table 1. Physical properties of the raw metals

原料 熔点/ ℃ 沸点/ ℃ 密度/ (g·cm-3) Ag 961.93 2213 10.53 Cu 1083.40 2567 8.96 In 156.61 2060 7.30 Sn 232.00 2270 7.28 注:高铟高锡银基钎料的熔点为600~650 ℃[6]。 表 2 高速压制成形过程数值模拟参数

Table 2. Simulation parameters of high speed electromagnetic compaction process

变量 刚度系数 恢复系数 静摩擦系数 滚动摩擦系数 上模初始速度/ (m·s-1) 数值 1.2 0.2 0.3 0.1 100 表 3 各区域压坯相对密度

Table 3. Relative density of compact in different partition

时间/ s 上部 中部 下部 1.0×10-5 0.5796730 0.6323840 0.6070890 1.5×10-5 0.6632130 0.7109370 0.6655910 2.0×10-5 0.7474480 0.7807180 0.7421550 2.5×10-5 0.8333330 0.8393670 0.8262590 3.0×10-5 0.9032913 0.9087015 0.8954010 注:相对密度为实际密度与理论密度的比值,理论密度可以根据成分加权算出。 表 4 压坯相对密度随时间的变化规律

Table 4. Relationship between the relative density of compact with time

时间/ s Ag–19.5Cu–30In Ag–19.5Cu–15In–15Sn Ag–19.5Cu–30Sn 1.0×10-5 0.606098261 0.605965121 0.605948597 2.0×10-5 0.757089633 0.756272334 0.756246597 3.0×10-5 0.913675210 0.901737648 0.901696994 4.0×10-5 0.989807742 0.989751127 0.989707047 5.0×10-5 0.997195101 0.997083531 0.997033824 -

[1] Zhang Q Y, Zhuang H S. Brazing and Soldering Manual. 2nd Ed. Beijing: China Machine Press, 2008张启运, 庄鸿寿.钎焊手册. 2版.北京: 机械工业出版社, 2008 [2] Lin L H, Diao X G, Luo H B. Research status and development trend of domestic and foreign brazing of dissimilar materials. Weld Technol, 2016, 45(8): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-HSJJ201608001.htm林丽恒, 刁晓刚, 罗海波.国内外异种材料钎焊的研究现状及发展趋势.焊接技术, 2016, 45(8): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-HSJJ201608001.htm [3] Sun B. Study on Production Technology and Microstructure Properties of Ag-Cu-P-Ge Solder for Electronic Packaging Materials[Dissertation]. Changsha: Central South University, 2009孙斌. Ag-Cu-P-Ge系电子封装中温钎料生产工艺及组织性能研究, 长沙: 中南大学, 2009 [4] Qiu F S. Development of the Solder Paste for Aluminum Soldering and Solder Wires for Automated Soldering in Electronic Packaging[Dissertation]. Guangzhou: South China University of Technology, 2015丘富顺.电子封装自动软钎焊用焊铝锡膏和焊锡丝的研制, 广州: 华南理工大学, 2015 [5] Zhang L S. The Study of Low-Melting-Point Filler Metal for Al-Si-Mg Series Alloys Vacuum Brazing[Dissertation]. Tianjin: Hebei University of Technology, 2006张连生. Al-Si-Mg系锻铝合金真空钎焊低熔点钎料的研究, 天津: 河北工业大学, 2006 [6] Liu Y Z, Hu J H, Huang S Y, et al. Densification behavior of powder pressing for Ag-Cu solder. Forg Stamp Technol, 2018, 43(4): 76 https://www.cnki.com.cn/Article/CJFDTOTAL-DYJE201804018.htm刘运展, 胡建华, 黄尚宇, 等. Ag-Cu钎料粉末压制致密化行为.锻压技术, 2018, 43(4): 76 https://www.cnki.com.cn/Article/CJFDTOTAL-DYJE201804018.htm [7] Hu F, Hu J H, Hu X H, et al. Influence of liquid sintering parameters of electromagnetic pressing BAg45Cu28Zn25Sn2 solder on mechanical properties of brazed joint. Hot Working Technol, 2018, 47(5): 29 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201805007.htm胡飞, 胡建华, 胡晓华, 等.电磁压制BAg45Cu28Zn25Sn2钎料的液相烧结参数对钎焊接头力学性能的影响.热加工工艺, 2018, 47(5): 29 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201805007.htm [8] Yan S W, Huang S Y, Hu J H, et al. Development and application of numerical simulation in powder metallurgy manufacturing. Powder Metall Technol, 2017, 35(1): 57 doi: 10.3969/j.issn.1001-3784.2017.01.010颜士伟, 黄尚宇, 胡建华, 等.数值仿真技术在粉末冶金零件制造中的应用及研究进展.粉末冶金技术, 2017, 35(1): 57 doi: 10.3969/j.issn.1001-3784.2017.01.010 [9] Nosewicz S, Rojek J, Chmielewski M, et al. Discrete element modeling and experimental investigation of hot pressing of intermetallic NiAl powder. Adv Powder Technol, 2017, 28(7): 1745. doi: 10.1016/j.apt.2017.04.012 [10] Criss E M, Meyers M A. Braze welding of cobalt with a silver-copper filler. J Mater Res Technol, 2015, 4(1): 44. doi: 10.1016/j.jmrt.2014.11.002 [11] Meng Z H, Huang S Y, Yang M. Effects of processing parameters on density and electric properties of electric ceramic compacted by low-voltage electromagnetic compaction. J Mater Process Technol, 2009, 209(2): 672. doi: 10.1016/j.jmatprotec.2008.02.038 [12] Zhang X P, Shi Y W. A dissolution model of base metal in liquid brazing filler metal during high temperature brazing. Scr Mater, 2004, 50(7): 1003. doi: 10.1016/j.scriptamat.2003.12.032 [13] Yang T Y, Zhang D K, Wang K H, et al. Effect of strontium and SmO on the microstructure and fracture mode of AlSi-Mg2Si brazing filler metal. J Rare Earths, 2016, 34(2): 187. doi: 10.1016/S1002-0721(16)60013-3 [14] Li H, Tillmann W, Li Z X, et al. Development and application of high quality and high reliability brazing filler materials. Trans China Weld Inst, 2014, 35(4): 108 https://www.cnki.com.cn/Article/CJFDTOTAL-HJXB201404026.htm李红, Tillmann W, 栗卓新, 等.高品质高可靠性钎料的技术发展和应用.焊接学报, 2014, 35(4): 108 https://www.cnki.com.cn/Article/CJFDTOTAL-HJXB201404026.htm [15] Wang W, Huang S Y, Liao X, et al. Sintering process and wetting properties of Ag-Cu-In-Sn filler metal with electromagnetic compaction. Hot Working Technol, 2016, 45(19): 166 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201619050.htm王苇, 黄尚宇, 廖行, 等.电磁压制Ag-Cu-In-Sn钎料烧结工艺及润湿性能的研究.热加工工艺, 2016, 45(19): 166 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201619050.htm [16] Liu Y, Li Y M, Xia Q K, et al. Experimental study on discrete element simulation of powder injection molding. JMater Eng, 2014(4): 85 doi: 10.3969/j.issn.1001-4381.2014.04.015刘煜, 李益民, 夏卿坤, 等.粉末注射成形的离散元模拟实验研究.材料工程, 2014(4): 85 doi: 10.3969/j.issn.1001-4381.2014.04.015 [17] Shen X P, Xu G S. Defect analysis of powder metallurgy compact. Powder Metall Technol, 2012, 30(4): 279 doi: 10.3969/j.issn.1001-3784.2012.04.007申小平, 许桂生.粉末冶金压坯缺陷分析.粉末冶金技术, 2012, 30(4): 279 doi: 10.3969/j.issn.1001-3784.2012.04.007 -

下载:

下载: