Research on the process optimization of selective laser melting and the mechanical properties of 18Ni300 die steel

-

摘要: 优化激光选区熔化工艺, 制备18Ni300模具钢试样, 研究扫描速度和激光功率对模具钢力学性能的影响。结果表明, 当激光功率保持不变时, 随着扫描速度的增加, 18Ni300模具钢试样的相对密度和综合力学性能先增大后减小; 当扫描速度保持不变时, 随着激光功率的增加, 试样相对密度和综合力学性能逐渐增大; 能量密度在150 J·mm-3左右时, 试样的相对密度达到最高。激光选区熔化最优工艺参数是激光功率175W, 扫描速度400mm·s-1, 在此工艺参数下成形件的相对密度为99.58%, 抗拉强度、显微硬度和断后伸长率分别为1101 MPa、HV 348.4和6.44%。Abstract: The 18 Ni300 die steels were prepared by the optimized selective laser melting, and the effects of scanning speed and laser power on the mechanical properties of 18 Ni300 die steels were studied.The results show that, when the laser power is constant, the relative density and the comprehensive mechanical properties of 18 Ni300 die steel specimen increase first and then decrease with the increase of scanning speed.When the scanning speed is constant, the relative density and the comprehensive mechanical properties increase with the increase of laser power.When the laser energy density is about 150 J·mm-3, the relative density of specimen is the highest.At the optimal scanning speed and laser power of 400 mm·s-1 and 175 W, the relative density, tensile strength, microhardness, and elongation of specimen are 99.58%, 1101 MPa, HV 348.4, and 6.44%, respectively.

-

Key words:

- selective laser melting /

- die steel /

- process optimization /

- mechanical properties

-

图 6 激光功率为175 W时, 不同扫描速度下试样的光学显微组织和综合力学性能: (a) 200 mm·s-1; (b) 400 mm·s-1; (c) 600 mm·s-1; (d) 800 mm·s-1; (e) 1000 mm·s-1; (f)综合力学性能

Figure 6. Optical microstructures and comprehensive properties of the specimens at different scanning speeds at 175 W: (a) 200 mm·s-1; (b) 400 mm·s-1; (c) 600 mm·s-1; (d) 800 mm·s-1; (e) 1000 mm·s-1; (f) the comprehensive mechanical properties

图 7 扫描速度为400 mm·s-1时, 不同激光功率下试样的光学显微组织和综合力学性能: (a) 75 W; (b) 100 W; (c) 125 W; (d) 150 W; (e) 175 W; (f)综合力学性能

Figure 7. Optical microstructures and comprehensive properties of the specimens at different laser powers at 400 mm·s-1: (a) 75 W; (b) 100 W; (c) 125 W; (d) 150 W; (e) 175 W; (f) the comprehensive mechanical properties

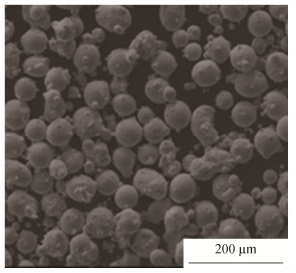

表 1 18Ni300合金粉末化学成分(质量分数)

Table 1. Chemical composition of 18Ni300 alloy powders/%

Ni Co Mo Ti Al Si Mn Fe 18.530 8.980 4.880 0.660 0.104 0.042 0.018 余量 -

[1] Guo D H, Feng T, Duan G Q, et al. Application of injection mould with conformal cooling channel based on SLM. Electromach Mould, 2017(6): 42 doi: 10.3969/j.issn.1009-279X.2017.06.011郭东海, 冯涛, 段国庆, 等.基于SLM成形随形冷却水道注塑模具的应用.电加工与模具, 2017(6): 42 doi: 10.3969/j.issn.1009-279X.2017.06.011 [2] Liu B, Tan J H, Wu C L. Design of injection mould with conformal cooling channel based on 3D printing. Eng Plast Appl, 2015, 43(10): 71 doi: 10.3969/j.issn.1001-3539.2015.10.014刘斌, 谭景焕, 吴成龙.基于3D打印的随形冷却水道注塑模具设计.工程塑料应用, 2015, 43(10): 71 doi: 10.3969/j.issn.1001-3539.2015.10.014 [3] Shi Y S, Wu Z G, Wei Q S, et al. Effects of conformal cooling channel on injection molding and production efficiency. J Huazhong Univ Sci Technol Nat Sci, 2007, 35(3): 60 doi: 10.3321/j.issn:1671-4512.2007.03.018史玉升, 伍志刚, 魏青松, 等.随形冷却对注塑成型和生产效率的影响.华中科技大学学报(自然科学版), 2007, 35(3): 60 doi: 10.3321/j.issn:1671-4512.2007.03.018 [4] Casavola K, Campanelli S L, Pappalettere C. Preliminary investigation on the residual strain distribution due to the selective laser melting process. J Strain Anal Eng Des, 2009, 44(1): 93. doi: 10.1243/03093247JSA464 [5] Campanelli S L, Contuzzi N, Angelastro A, et al. Capabilities and performances of the selective laser melting process//In Tech. New Trends in Technologies: Devices, Computer, Communication and Industrial Systems, Eds by Meng Joo Er, 2010. http://www.researchgate.net/publication/221909648_Capabilities_and_Performances_of_the_Selective_Laser_Melting_Process [6] Tavares S S M, Abreu H F G, Neto J M, et al. Athermomagnetic study of the martensite-austenite phase transition in the maraging 350 steel. J Alloys Compd, 2003, 358(1-2): 152. doi: 10.1016/S0925-8388(03)00335-9 [7] Pardal J M, Tavares S S M, Terra V F, et al. Modeling of precipitation hardening during the aging and overaging of18Ni-Co-Mo-Ti maraging 300 steel. J Alloys Compd, 2005, 393(1-2): 109. doi: 10.1016/j.jallcom.2004.09.049 [8] Kang K. 18Ni-300 Powder Characteristics Used in Selective Laser Melting and Microstructure of Selective Laser Melted 18Ni-300 Steel[Dissertation]. Chongqing: Chongqing University, 2014康凯.选区激光成形用18Ni-300粉末特性及成形件组织结构的研究, 重庆: 重庆大学, 2014 [9] Chao R C. Study on the Fabrication Process of 18Ni300Maraging Steel by Selective Laser Melting and the Experimental Analysis on Laser Melting of Metal Powders[Dissertation]. Shanghai: Shanghai JiaoTong University, 2014曹润辰. 18Ni300马氏体时效钢选区激光熔化工艺及金属粉末激光熔化实验研究, 上海: 上海交通大学, 2014 [10] Zhou Y Y, Wang F, Xue C. Microstructure and mechanical properties of 3D printing 18Ni300 die steel. Phys Test Chem Anal Part A Phys Test, 2016, 52(4): 243 https://www.cnki.com.cn/Article/CJFDTOTAL-LHJW201604009.htm周隐玉, 王飞, 薛春. 3D打印18Ni300模具钢的显微组织及力学性能.理化检验(物理分册), 2016, 52(4): 243 https://www.cnki.com.cn/Article/CJFDTOTAL-LHJW201604009.htm [11] Contuzzi N, Campanelli S L, Casavola C, et al. Manufacturing and characterization of 18Ni marage 300lattice components by selective laser melting. Materials, 2013, 6(8): 3451. doi: 10.3390/ma6083451 [12] Casalino G, Campanelli S L, Contuzzi N, et al. Experimental investigation and statistical optimisation of the selective laser melting process of a maraging steel. Opt Laser Technol, 2015, 65: 151. doi: 10.1016/j.optlastec.2014.07.021 [13] Ciurana J, Hernandez L, Delgado J. Energy density analysis on single tracks formed by selective laser melting with CoCrMo powder material. Int J Adv Manuf Technol, 2013, 68(5-8): 1103. doi: 10.1007/s00170-013-4902-4 -

下载:

下载: