Research progress on titanium and titanium alloys used as implant materials for human body

-

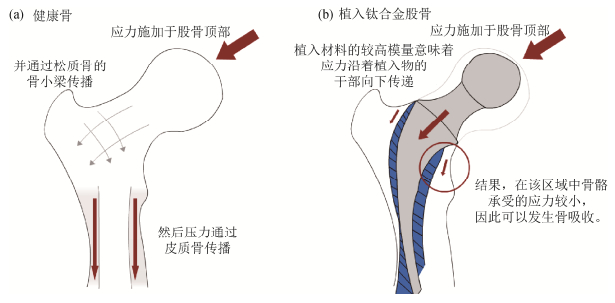

摘要: 钛及其合金因其具有低密度、高比强度、低弹性模量、良好的生物相容性和耐蚀性等特点, 被认为是一种理想的人体植入金属材料, 广泛应用于骨关节替换、牙齿修复等方面, 且对其的需求量快速增长; 同时, 钛也存在骨整合率低、抗菌性差、耐磨性差等缺陷, 急需进一步研究和改进。本文介绍了钛及钛合金作为人体植入材料的优异特性, 概述了国内外关于新型β型钛合金、表面改性钛合金、多孔钛合金、钛-陶复合材料的研究进展, 总结了钛及钛合金材料存在的一些问题, 为新型钛及钛合金材料的设计研发, 钛及钛合金综合性能的优化, 钛及钛合金使用寿命的延长提供参考。Abstract: Titanium and titanium alloys are considered as an ideal metal material for human implants because of low density, high specific strength, low elasticity modulus, good biocompatibility, and corrosion resistance.It is widely used in joint replacement and dental restoration, and the demand for titanium and titanium alloys is increasing rapidly.However, the titanium and titanium alloys have the defects to be further studied and improved, such as low osseointegration rate, poor antibacterial property, and low wear resistance.The excellent properties of titanium and titanium alloys were introduced, the research progress on new β-type titanium alloys, surface-modified titanium alloys, porous titanium alloys, and titanium-ceramic composites alloys for human implant materials was summarized, and some problems in the development of titanium alloy materials were discussed in this paper, which provide the reference to design the new human implant materials, optimize the overall performance, and extend the service life of titanium and titanium alloys.

-

图 3 添加不同质量分数NH4HCO3发泡剂制备的具有不同孔隙率的Ti–20Nb–15Zr钛合金显微形貌: (a) 0%NH4HCO3, 孔隙率6.06%; (b) 20%NH4HCO3, 孔隙率37.9%; (c) 35%NH4HCO3, 孔隙率50.5%; (d) 50%NH4HCO3, 孔隙率62.8%[16]

Figure 3. SEM images of Ti–20Nb–15Zr alloys in different porosities prepared by NH4HCO3 in different mass fractions as foaming agent: (a) 0%NH4HCO3, porosity 6.06%; (b) 20%NH4HCO3, porosity 37.9%; (c) 35%NH4HCO3, porosity 50.5%; (d) 50%NH4HCO3, porosity 62.8%[16]

图 4 多孔材料孔隙大小对细胞增殖行为的影响: (a) 50μm; (b) 100μm; (c) 150μm; (d) 200μm; (e) 300μm; (f)图(e)中孔内部结构[18]

Figure 4. Effect of pore sizes for porous materials on cell proliferation behavior: (a) 50μm; (b) 100μm; (c) 150μm; (d) 200μm; (e) 300μm; (f) the internal structure of pores in

-

[1] Bothe R T, Beaton L E, Davenport H A, et al. Reaction of bone to multiple metallic implants. Surg Gynecol Obstet, 1940, 71(6): 598. http://ci.nii.ac.jp/naid/10007734955 [2] Shi C X. Comprehensive Dictionary of Materials. Beijing: Chemical Industry Press, 1994师昌绪.材料大辞典.北京: 化学工业出版社, 1994 [3] Zhan W G. The research, production and application of titanium and titanium alloy for medical functional materials. Titanium Ind Prog, 2007, 24(1): 4 https://www.cnki.com.cn/Article/CJFDTOTAL-TGYJ200701003.htm詹文革.生物医用钛及钛合金的研制、生产和应用.钛工业进展, 2007, 24(1): 4 https://www.cnki.com.cn/Article/CJFDTOTAL-TGYJ200701003.htm [4] DoITPoMS. Materials selection of femoral stem component. Cambridge, University of Cambridge, 2006.http://www.doitpoms.ac.uk/tlplib/bones/stem.php. [5] Sakaguchi N, Niinomi M, Akahori T, et al. Effect of Ta content on mechanical properties of Ti-30Nb-XTa-5Zr. Mater Sci Eng C, 2005, 25(3): 370. doi: 10.1016/j.msec.2005.04.003 [6] Li Y Y, Zou L M, Yang C. Fabrication of biomedical titanium alloys with high strength and low modulus by means of powder metallurgy. J South China Univ Technol Nat Sci, 2012, 40(10): 43 https://www.cnki.com.cn/Article/CJFDTOTAL-HNLG201210007.htm李元元, 邹黎明, 杨超.粉末冶金法合成高强低模超细晶医用钛合金.华南理工大学学报(自然科学版), 2012, 40(10): 43 https://www.cnki.com.cn/Article/CJFDTOTAL-HNLG201210007.htm [7] Raducanu D, Vasilescu E, Cojocaru V D, et al. Mechanical and corrosion resistance of a new nanostructured Ti-Zr-Ta-Nb alloy. J Mech Behav Biomed Mater, 2011, 4(7): 1421. doi: 10.1016/j.jmbbm.2011.05.012 [8] Zhang R, Wan Y, Ai X, et al. Preparation of micro-nanostructure on titanium implants and its bioactivity. Trans Nonferrous Met Soc China, 2016, 26(4): 1019. doi: 10.1016/S1003-6326(16)64217-6 [9] Kim H G, Ahn S H, Kim J G, et al. Corrosion performance of diamond-like carbon(DLC)-coated Ti alloy in the simulated body fluid environment. Diamond Relat Mater, 2005, 14(1): 35. doi: 10.1016/j.diamond.2004.06.034 [10] Kim J G, Lee K R, Yang S J. Wear-corrosion performance of Si-DLC coatings on Ti-6Al-4V substrate. J Biomed Mater Res Part A, 2008, 86(1): 41. doi: 10.1002/jbm.a.31632/full [11] Hauert R, Falub C V, Thorwarth G, et al. Retrospective lifetime estimation of failed and explanted diamond-like carbon coated hip joint balls. Acta Biomater, 2012, 8(8): 3170. doi: 10.1016/j.actbio.2012.04.016 [12] Liu X Y, Chu P K, Ding C X. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater Sci Eng R, 2004, 47(3-4): 49. doi: 10.1016/j.mser.2004.11.001 [13] Kim S K, Lee J B, Koak J Y, et al. An abutment screw loosening study of a diamond like carbon-coated CPtitanium implant. J Oral Rehabil, 2005, 32(5): 346. doi: 10.1111/j.1365-2842.2004.01475.x [14] Korn P, Schulz M C, Hintze V, et al. Chondroitin sulfate and sulfated hyaluronan-containing collagen coatings of titanium implants influence peri-implant bone formation in a minipig model. J Biomed Mater Res A, 2014, 102(7): 2334. doi: 10.1002/jbm.a.34913 [15] Tsukanaka M, Yamamoto K, Fujibayashi S, et al. Evaluation of bioactivity of alkali-and heat-treated titanium using fluorescent mouse osteoblasts. J Bone Miner Metab, 2014, 32(6): 660. doi: 10.1007/s00774-013-0544-8 [16] Rao X, Chu C L, Zheng Y Y. Phase composition, microstructure, and mechanical properties of porous Ti-Nb-Zr alloys prepared by a two-step foaming powder metallurgy method. J Mech Behav Biomed Mater, 2014, 34(6): 27. http://www.ncbi.nlm.nih.gov/pubmed/24556322 [17] Hollander D A, von Walter M, Wirtz T, et al. Structural, mechanical and in vitro characterization of individually structured Ti-6Al-4V produced by direct laser forming. Biomaterials, 2006, 27(7): 955. doi: 10.1016/j.biomaterials.2005.07.041 [18] Xue W C, Krishna B V, Bandyopadhyay A, et al. Processing and biocompatibility evaluation of laser processed porous titanium. Acta Biomater, 2007, 3(6): 1007. doi: 10.1016/j.actbio.2007.05.009 [19] Attar H, Löber L, Funk A, et al. Mechanical behavior of porous commercially pure Ti and Ti-TiB composite materials manufactured by selective laser melting. Mater Sci Eng A, 2015, 625: 350. doi: 10.1016/j.msea.2014.12.036 [20] Mao M Y. Mechanical Properties and Biocompatibility of Porous Ti6Al4V Implant Fabricated by Selective Laser Sintering[Dissertation]. Jinan: Shandong University, 2016毛梦芸.选择性激光烧结制备多孔钛的机械性能与生物相容性研究, 济南: 山东大学, 2016 [21] Yan Y J. Preparation and Bioactivity of Calcium Phosphate/TiO2 Nanotube Composite Coating on Titanium[Dissertation]. Chengdu: University of Electronic Science and Technology of China, 2015严雅静.金属钛表面TiO2纳米管磷灰石复合涂层的制备与生物活性研究, 成都: 电子科技大学, 2015 [22] Zhang X W. Research of Osteogenesis Enhancement Function of Additively Manufactured Porous Ti Implants Combined with CS/HA Coating[Dissertation]. Jinan: Shandong University, 2016张欣蔚. 3D打印多孔钛种植体结合CS/HA涂层促骨结合作用的研究, 济南: 山东大学, 2016 [23] Niespodziana K, Jurczyk K, Jakubowicz J, et al. Fabrication and properties of titanium-hydroxyapatite nanocomposites. Mater Chem Phys, 2010, 123(1): 160. doi: 10.1016/j.matchemphys.2010.03.076 [24] Xie C M, Lu X, Wang K F, et al. Silver nanoparticles and growth factors incorporated hydroxyapatite coatings on metallic implant surfaces for enhancement of osteoinductivity and antibacterial properties. ACS Appl Mater Interfaces, 2014, 6(11): 8580. doi: 10.1021/am501428e [25] Kirmanidou Y, Sidira M, Drosou M E, et al. New Ti-alloys and surface modifications to improve the mechanical properties and the biological response to orthopedic and dental implants: a review. Biomed Res Int, 2016, 2016(2): 2908570. http://downloads.hindawi.com/journals/bmri/2016/2908570.xml -

下载:

下载: