Effects of additive Nb and sintering temperature on the properties of ZrN powder materials

-

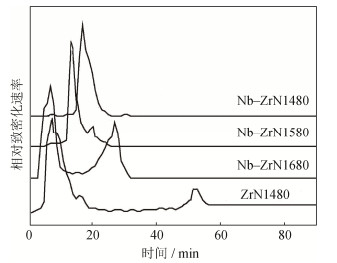

摘要: 在ZrN粉末中添加Nb粉,经热压烧结得到Nb-ZrN粉末材料,研究添加剂Nb与烧结温度对Nb-ZrN材料烧结和力学性能的影响。结果表明:提高烧结温度有利于加快材料的致密化,Nb-ZrN1480粉末出现了1个致密化速率峰,其它粉末材料还生成了另外2个小的致密化速率峰,烧结Nb-ZrN1680粉末的相对密度达到98.6%。各粉末材料的X射线衍射谱图中都存在ZrO2衍射峰,添加剂Nb在烧结阶段全部溶入ZrN内。添加Nb后,ZrN晶格常数减小,随烧结温度上升,ZrN晶格常数基本保持稳定。纯ZrN材料表现为沿晶断裂,添加Nb后,粉末材料发生穿晶断裂,气孔数明显降低。Abstract: The Nb-ZrN powder materials were prepared by hot pressing sintering, adding Nb powders as the additive in ZrN matrix. Effects of additive Nb and sintering temperature on the sintering and mechanical properties of ZrN powder materials were researched. The results show that, the increase of sintering temperature benefits the material densification, a densification rate peak is present in Nb-ZrN1480 powder materials, and two other small rate peak appear in other Nb-ZrN powder materials. The relative density of Nb-ZrN1680 powders after sintering can achieve as high as 98.6%. The diffraction peak of ZrO2 is found in X-ray diffraction spectra of all Nb-ZrN powders, the additive Nb dissolves into the ZrN matrix in sintering stage. After adding Nb as the additive, the ZrN lattice constant reduces and then remains stable with the increase of sintering temperature. Pure ZrN shows the intergranular fracture, the Nb-ZrN powder materials exhibit the transgranular fracture, and the number of pore is decreased obviously.

-

Key words:

- powder materials /

- additives /

- sintering temperature /

- relative density /

- mechanical properties

-

表 1 Nb-ZrN粉末材料组成及对应烧结温度

Table 1. Composition of Nb-ZrN powder materials and the corresponding sintering temperature

材料编号 材料组成(质量分数)/ % 烧结温度/℃ Nb ZrN ZrN1580 0 100 1580 Nb-ZrN1480 8 92 1480 Nb-ZrN1580 8 92 1580 Nb-ZrN1680 8 92 1680 表 2 Nb-ZrN粉末材料的物理和力学性能

Table 2. Physical and mechanical properties of Nb-ZrN powder materials

材料编号 相对密度/% 弹性模量/GPa 维氏硬度/GPa 断裂韧性/(MPa·m1/2) 屈服强度/MPa ZrN1580 97.8 232 10.4 4.2 108 Nb-ZrN1480 97.1 266 12.3 5.8 286 Nb-ZrN1580 98.6 252 11.2 6.6 412 Nb-ZrN1680 98.0 248 11.8 6.2 336 -

[1] Su G K, Tan D W, Guo W M, et al. Preparation of Si3N4–ZrSi2–ZrN–BN ceramic by reactive hot pressing and its processing properties. J Chin Ceram Soc, 2017, 45(6): 823 https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201706012.htm苏国康, 谭大旺, 郭伟明, 等. 反应热压烧结Si3N4–ZrSi2–ZrN–BN陶瓷及其加工性能. 硅酸盐学报, 2017, 45(6): 823 https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201706012.htm [2] Lü L, Yu Z M. Preparation and properties of TiN/ZrN anti-erosion multilayer coatings. Mater Res Appl, 2016, 10(1): 28 doi: 10.3969/j.issn.1673-9981.2016.01.006吕亮, 余志明. TiN/ZrN抗冲蚀多层膜制备及其性能研究. 材料研究与应用, 2016, 10(1): 28 doi: 10.3969/j.issn.1673-9981.2016.01.006 [3] Lei R S, Chen G R, Wang M P. Effect of Nb solute concentration on crystallite size refinement and strength enhancement in mechanically alloyed Cu-Nb alloys. Rare Met Mater Eng, 2018, 47(9): 2607 doi: 10.1016/S1875-5372(18)30196-6 [4] Zhang Z, Yao X X, Ge P. Phase-field simulation of microstructures of Ti-Nb alloys in laser powder deposition additive manufacturing. Ordn Mater Sci Eng, 2018, 41(5): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG201805002.htm张昭, 姚欣欣, 葛芃. Ti-Nb合金激光粉末沉积增材制造显微组织的相场模拟. 兵器材料科学与工程, 2018, 41(5): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-BCKG201805002.htm [5] Yang Y, Jia J B, Liu W C, et al. Vacuum hot-pressing sintering processes for a powder metallurgy Ti-22Al-25Nb alloy. China Mech Eng, 2018, 29(10): 1227 doi: 10.3969/j.issn.1004-132X.2018.10.015杨越, 贾建波, 刘文超, 等. 粉末冶金Ti-22Al-25Nb合金的真空热压烧结工艺. 中国机械工程, 2018, 29(10): 1227 doi: 10.3969/j.issn.1004-132X.2018.10.015 [6] Liu H, Ma H W, Li X C, et al. Effect of ZrN-Sialon composite powder on properties of Al2O3-C refractory. J Synth Cryst, 2018, 47(2): 280 doi: 10.3969/j.issn.1000-985X.2018.02.008刘贺, 马鸿文, 李小超, 等. ZrN-Sialon复相粉体对Al2O3-C耐火材料性能的影响. 人工晶体学报, 2018, 47(2): 280 doi: 10.3969/j.issn.1000-985X.2018.02.008 [7] Mao S B, Zhang L, Zhang S H. Influence of substrate bias voltage on microstructures and mechanical properties of ZrN coatings. Chin J Vac Sci Technol, 2017, 37(9): 916 https://www.cnki.com.cn/Article/CJFDTOTAL-ZKKX201709013.htm毛绍宝, 张林, 张世宏. 基体偏压对ZrN涂层微观结构及力学性能的影响. 真空科学与技术学报, 2017, 37(9): 916 https://www.cnki.com.cn/Article/CJFDTOTAL-ZKKX201709013.htm [8] Guo Y, Liu Z M, Su P F, et al. Microstructure and mechanical properties of nitride dispersion strengthened ferrite-based alloy. Powder Metall Technol, 2016, 34(5): 361 doi: 10.3969/j.issn.1001-3784.2016.05.008郭旸, 刘祖铭, 苏鹏飞, 等. 氮化物弥散强化铁基合金的显微组织和力学性能研究. 粉末冶金技术, 2016, 34(5): 361 doi: 10.3969/j.issn.1001-3784.2016.05.008 [9] Yin Y, Ma B Y. The latest development of inorganic powder materials preparation by molten salt synthesis. Rare Met Cem Carb, 2016, 44(4): 66 https://www.cnki.com.cn/Article/CJFDTOTAL-XYJY201604016.htm尹月, 马北越. 熔盐合成法制备无机粉末材料新进展. 稀有金属与硬质合金, 2016, 44(4): 66 https://www.cnki.com.cn/Article/CJFDTOTAL-XYJY201604016.htm [10] Lu F G, Qiu L X, Ding Z H, et al. High-pressure synthesis and properties characterization of ZrN-ZrB2 nanocomposites. Chin J High Press Phys, 2011, 25(2): 104 https://www.cnki.com.cn/Article/CJFDTOTAL-GYWL201102001.htm陆凤国, 邱利霞, 丁战辉, 等. ZrN-ZrB2纳米复合材料的高压制备及性能表征. 高压物理学报, 2011, 25(2): 104 https://www.cnki.com.cn/Article/CJFDTOTAL-GYWL201102001.htm [11] Huang R X, Qi Z B, Sun P, et al. Effect of deposition temperature on structure and mechanical properties of ZrN nano-coatings. J Xiamen Univ Nat Sci, 2010, 49(5): 654 https://www.cnki.com.cn/Article/CJFDTOTAL-XDZK201005015.htm黄若轩, 祁正兵, 孙鹏, 等. 沉积温度对纳米ZrN涂层结构及性能的影响. 厦门大学学报(自然科学版), 2010, 49(5): 654 https://www.cnki.com.cn/Article/CJFDTOTAL-XDZK201005015.htm [12] Xu Y S, Zheng L F, Lu M S, et al. Study on process and performance of TiN coating deposited onto cemented carbides cutting. Hot Working Technol, 2010, 39(6): 97 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201006033.htm徐玉松, 郑莉芬, 陆敏松, 等. TaCp增强YG11C合金表面改性工艺及性能研究. 热加工工艺, 2010, 39(6): 97 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201006033.htm [13] Li F Q, Hong R J, Yu Z M, et al. Microstructure and corrosion resistance of Ti/TiN/Zr/ZrN multilayer film deposited by cathodic ion plating in vacuum. Mater Prot, 2009, 42(10): 17 https://www.cnki.com.cn/Article/CJFDTOTAL-CLBH200910007.htm李福球, 洪瑞江, 余志明, 等. 真空阴极离子镀法制备Ti/TiN/Zr/ZrN多层膜. 材料保护, 2009, 42(10): 17 https://www.cnki.com.cn/Article/CJFDTOTAL-CLBH200910007.htm [14] Xu X M, Wang J, Zhao Y, et al. Effect of interface and preferred orientation on the hardness of TiN/ZrN multilayers. Acta Phys Sin, 2006, 55(10): 5380 https://www.cnki.com.cn/Article/CJFDTOTAL-WLXB200610065.htm徐晓明, 王娟, 赵阳, 等. 界面和择优取向对TiN/ZrN纳米多层膜硬度变化的影响. 物理学报, 2006, 55(10): 5380 https://www.cnki.com.cn/Article/CJFDTOTAL-WLXB200610065.htm [15] He Z Y, Shan W R, Zhang Y Q, et al. Effects of sintering temperature on microstructure and mechanical properties of calcium pyrophosphate/Ti-35Nb-7Zr composite. Acta Mater Compos Sin, 2017, 34(5): 1009 https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201705011.htm何正员, 单文瑞, 张玉勤, 等. 烧结温度对焦磷酸钙/Ti-35Nb-7Zr复合材料微观组织及力学性能的影响. 复合材料学报, 2017, 34(5): 1009 https://www.cnki.com.cn/Article/CJFDTOTAL-FUHE201705011.htm -

下载:

下载: