Analysis on sintering driving force of unequal-sized particles in generalized thermoelastic diffusion

-

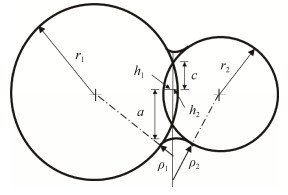

摘要: 在广义热弹性扩散理论框架下建立非等径两颗粒系统三维有限元模型,研究颗粒系统温度场和浓度场的分布规律,分析场分布对脉冲电流烧结初期迁移驱动力的影响。结果表明,颗粒颈部空位浓度梯度、温度梯度、由温度场和应力场产生的浓度梯度是颗粒颈部物质迁移的共同驱动力。烧结颈部的温度会产生两次突变,烧结过程中小颗粒一直保持高温状态;温度变化会引起浓度改变,使得颈部浓度高于边缘浓度;热扩散占总扩散通量的2/3,浓度扩散占1/3,因此烧结颈部的热扩散驱动力和浓度扩散驱动力是脉冲电流烧结过程的主导驱动力,提高热扩散能力和浓度扩散通量可显著提高烧结过程驱动力。非等径颗粒的烧结驱动力远远大于等径颗粒,为非等径颗粒的烧结比等径颗粒更为迅速提供了理论依据。Abstract: The three-dimensional finite element model of unequal-sized particles system was established based on the generalized thermoelastic diffusion, and the distributions of temperature field and concentration field were calculated to investigate the effect of migration driving force in the preliminary stage of pulse electric current sintering in the unequal-sized particles system. In the results, the vacancy concentration gradient, the temperature gradient, and the concentration gradient caused by the changes in temperature and stress are the common driving forces of material migration in particle neck. The numerical results show that, there are two sudden changes of temperatures in particle neck, and the small particles are kept at high temperature during sintering. The change of temperature causes the change of concentration, resulting the higher concentration in neck than in the edge of particles. The thermal diffusion is 2/3 of the total diffusion flux, and the concentration diffusion flux is 1/3, which means the thermal diffusion and concentration diffusion flux are the dominant driving force in pulse electric current sintering process. The driving force of unequal-sized particles is much larger than that of equal-sized particles, providing a theoretical basis for the faster sintering rate of unequal-sized particles in sintering experiments.

-

图 2 不同时刻颗粒颈部温度和浓度云图:(a)、(c)4.3×10-5 s温度云图;(b)、(d)4.5×10-5 s温度云图;(e)4.3×10-5 s浓度云图;(f)4.5×10-5 s浓度云图

Figure 2. Temperature and concentration nephograms of the particle neck at different times: (a), (c) temperature nephogram at 4.3×10-5 s; (b), (d) temperature nephogram at 4.5×10-5 s; (e) concentration nephogram at 4.3×10-5 s; (f) concentration nephogram at 4.5×10-5 s

-

[1] Antou G, Guyot P, Pradeilles N, et al. Identification of densification mechanisms of pressure-assisted sintering: application to hot pressing and spark plasma sintering of alumina. J Mater Sci, 2015, 50(5): 2327 doi: 10.1007/s10853-014-8804-0 [2] Hulbert D M, Anders A, Andersson J, et al. A discussion on the absence of plasma in spark plasma sintering. Scr Mater, 2009, 60(10): 835 doi: 10.1016/j.scriptamat.2008.12.059 [3] Roetzel W, Putra N, Das S K. Experiment and analysis for non-Fourier conduction in materials with non-homogeneous inner structure. Int J Therm Sci, 2003, 42: 541 doi: 10.1016/S1290-0729(03)00020-6 [4] Nowacki W. Dynamical problem of thermodiffusion in solids Ⅰ. Bull Acad Polon Sci Sér Sci Tech, 1974, 22: 55 http://www.ams.org/mathscinet-getitem?mr=353792 [5] Nowacki W. Dynamical problem of thermodiffusion in solids Ⅱ. Bull Acad Polon Sci Sér Sci Tech, 1974, 22: 205 [6] Nowacki W. Dynamical problem of thermodiffusion in solids Ⅲ. Bull Acad Polon Sci Sér Sci Tech, 1974, 22: 257 [7] Jiang R Q. Transient Impact Effects in Heat Conduction, Mass Diffusion, and Momentum Transfer. Beijing: Science Press, 1997姜任秋. 热传导、质扩散与动量传递中的瞬态冲击效应. 北京: 科学出版社, 1997 [8] Sherief H H, Hamza F A, Saleh H A. The theory of generalized thermoelastic diffusion. Int J Eng Sci, 2004, 42: 591 doi: 10.1016/j.ijengsci.2003.05.001 [9] Zhang L, Zhang X M, Chu Z X, et al. Effect of heat wave at the initial stage in spark plasma sintering. SpringerPlus, 2016, 5: 838 doi: 10.1186/s40064-016-2344-9 [10] Olevsky E A, Froyen L. Impact of thermal diffusion on densification during SPS. J Am Ceram Soc, 2009, 92(Suppl 1): S122 http://www.ingentaconnect.com/content/bsc/jace/2009/00000092/a00101s1/art00021 [11] Huai X L, Jiang R Q, Liu D Y, et al. Experimental and theoretical investigation on the non-fick effects during the rapid transit mass diffusion. J Eng Thermophys, 2000, 21(5): 595 doi: 10.3321/j.issn:0253-231X.2000.05.019淮秀兰, 姜任秋, 刘登瀛, 等. 快速瞬态传质过程中非费克效应的实验与理论研究. 工程热物理学报, 2000, 21(5): 595 doi: 10.3321/j.issn:0253-231X.2000.05.019 [12] Zhang L, Zhang X M, Zheng A J, et al. Influence of thermal diffusion flux on driving force in the initial stage of pulse electric current sintering. Powder Metall Technol, 2017, 35(2): 98 doi: 10.3969/j.issn.1001-3784.2017.02.004张龙, 张晓敏, 郑安节, 等. 热扩散对脉冲电流烧结初期驱动力的影响. 粉末冶金技术, 2017, 35(2): 98 doi: 10.3969/j.issn.1001-3784.2017.02.004 [13] Wang C, Cheng L F, Zhao Z. FEM analysis of the temperature and stress distribution in spark plasma sintering: Modelling and experimental validation. Comput Mater Sci, 2010, 49: 351 doi: 10.1016/j.commatsci.2010.05.021 [14] Kumar R, Ahuja S, Garg S K. Numerical analysis of the propagation characteristics of Stoneley waves at an interface between microstretch thermoelastic diffusion solid half spaces. Lat Am J Solids Struct, 2014, 11(13): 2408 doi: 10.1590/S1679-78252014001300005 [15] Zhao S X, Song X Y, Wei C B, et al. Spark plasma sintering WC–Co mixed powders of various grain size matching. Mater Sci Eng Powder Metall, 2010, 15(1): 32 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201001009.htm赵世贤, 宋晓艳, 魏崇斌, 等. 放电等离子烧结不同粒径匹配的WC–Co混合粉末. 粉末冶金材料科学与工程, 2010, 15(1): 32 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201001009.htm -

下载:

下载: