Study on oxide inclusions of nickel-based P/M superalloy FHG96 by computed tomography technology

-

摘要: 利用计算机断层扫描技术(computed tomography,CT)研究了FGH96镍基粉末高温合金内部Al2O3、SiO2及莫来石三种氧化物夹杂对不同工艺(热等静压工艺、热等静压+热挤压+等温锻造工艺及热等静压+等温锻造工艺)的敏感程度。结果表明:热等静压+等温锻造工艺能显著减小Al2O3夹杂物的尺寸和其在合金中的含量,采用热等静压+热挤压+等温锻造工艺最能有效减少SiO2夹杂物在合金中的含量,而莫来石夹杂对热等静压+热挤压+等温锻造工艺和热等静压+等温锻造工艺均较为敏感,且两种工艺对莫来石夹杂的作用效果类似。夹杂物在实际盘件中呈油饼状,极大地恶化了合金低周疲劳性能,且夹杂物越接近试样表面,试样的低周疲劳性能恶化越显著。热等静压+等温锻造工艺对减小三种夹杂的尺寸均有良好效果,这为人们选取合适工艺消除合金中氧化物夹杂提供了重要参考。Abstract: The sensitivity of oxide inclusions (Al2O3, SiO2, and mullite) in nickel-based powder metallurgy (P/M) superalloy (FGH96) to different processing technology was studied by computed tomography (CT) technology. The results show that, the process of hot isostatic pressing + isothermal forging can significantly reduce the Al2O3 inclusion size and decrease the content of Al2O3 inclusion in FGH96 alloy; the process of hot isostatic pressing + hot extrusion + isothermal forging can effectively reduce the content of SiO2 inclusion in the alloy; the mullite inclusions are sensitive to both the process of hot isostatic pressing + hot extrusion + isothermal forging and the process of hot isostatic pressing + isothermal forging, and the effects of the two processes are similar. The inclusions in the actual disc show the oil cake shaped, which greatly deteriorates the low cycle fatigue properties of the alloy. The closer the inclusions are to the sample surface, the more obvious the deterioration of low cycle fatigue properties is. Overall, the process of hot isostatic pressing + isothermal forging shows the good effect on reducing the inclusion size, providing an important reference to eliminate the influence of inclusions in alloys by the appropriate process.

-

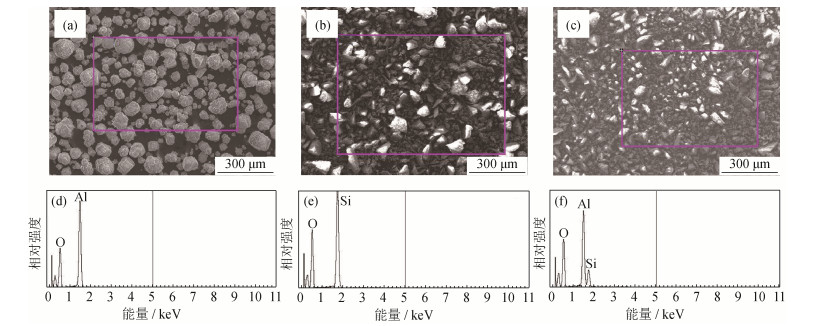

图 1 氧化物夹杂的显微形貌及能谱分析:(a)Al2O3夹杂物形貌;(b)SiO2夹杂物形貌;(c)Al2O3+SiO2混合夹杂物形貌;(d)Al2O3夹杂物能谱; (e)SiO2夹杂物能谱; (f)Al2O3+SiO2混合夹杂物能谱

Figure 1. Scanning electron microscopy (SEM) and energy dispersion spectrum (EDS) of oxide inclusions: (a) SEM of Al2O3; (b) SEM of SiO2; (c) SEM of Al2O3+SiO2; (d) EDS of Al2O3; (e) EDS of SiO2; (f) EDS of Al2O3+SiO2

图 3 热等静压态样品内部夹杂物显微形貌及粒径分布:(a)Al2O3夹杂物形貌;(b)SiO2夹杂物形貌;(c)Al2O3+SiO2混合夹杂物形貌;(d)Al2O3夹杂物形貌放大图;(e)SiO2夹杂物形貌放大图;(f)Al2O3+SiO2混合夹杂物放大图;(g)Al2O3夹杂物晶粒尺寸分布;(h)SiO2夹杂物晶粒尺寸分布;(i)Al2O3+SiO2混合夹杂物晶粒尺寸分布

Figure 3. Scanning electron microscopy (SEM) and particle size distribution (PSD) of oxide inclusions in the as-HIPed samples: (a) SEM of Al2O3; (b) SEM of SiO2; (c) SEM of Al2O3+SiO2; (d) magnification SEM of Al2O3; (e) magnification SEM of SiO2; (f) magnification SEM of Al2O3+SiO2; (g) PSD of Al2O3; (h) PSD of SiO2; (i) PSD of Al2O3+SiO2

图 4 不同成形工艺下样品内部Al2O3夹杂物显微形貌及粒径分布:(a)HIP夹杂物形貌;(b)HEX夹杂物形貌;(c)HIF夹杂物形貌;(d)HIP夹杂物形貌放大图;(e)HEX夹杂物形貌放大图;(f)HIF混合夹杂物放大图;(g)HIP夹杂物晶粒尺寸分布;(h)HEX夹杂物晶粒尺寸分布;(i)HIF混合夹杂物晶粒尺寸分布

Figure 4. Scanning electron microscopy (SEM) and particle size distribution (PSD) of Al2O3 inclusions in different process conditions: (a) SEM of as-HIPed samples; (b) SEM of as-HEXed samples; (c) SEM of as-HIFed samples; (d) magnification SEM of as-HIPed samples; (e) magnification SEM of as-HEXed samples; (f) magnification SEM of as-HIFed samples; (g) PSD of as-HIPed samples; (h) PSD of as-HEXed samples; (i) PSD of as-HIFed samples

图 5 不同成形工艺下样品内部SiO2夹杂物显微形貌及粒径分布:(a)HIP夹杂物形貌;(b)HEX夹杂物形貌;(c)HIF夹杂物形貌;(d)HIP夹杂物形貌放大图;(e)HEX夹杂物形貌放大图;(f)HIF混合夹杂物放大图;(g)HIP夹杂物晶粒尺寸分布;(h)HEX夹杂物晶粒尺寸分布;(i)HIF混合夹杂物晶粒尺寸分布

Figure 5. Scanning electron microscopy (SEM) and particle size distribution (PSD) of SiO2 inclusions in different process conditions: (a) SEM of as-HIPed samples; (b) SEM of as-HEXed samples; (c) SEM of as-HIFed samples; (d) magnification SEM of as-HIPed samples; (e) magnification SEM of as-HEXed samples; (f) magnification SEM of as-HIFed samples; (g) PSD of as-HIPed samples; (h) PSD of as-HEXed samples; (i) PSD of as-HIFed samples

图 6 不同成形工艺下样品内部莫来石夹杂物显微形貌及粒径分布:(a)HIP夹杂物形貌;(b)HEX夹杂物形貌;(c)HIF夹杂物形貌;(d)HIP夹杂物形貌放大图;(e)HEX夹杂物形貌放大图;(f)HIF混合夹杂物放大图;(g)HIP夹杂物晶粒尺寸分布;(h)HEX夹杂物晶粒尺寸分布;(i)HIF混合夹杂物晶粒尺寸分布

Figure 6. Scanning electron microscopy (SEM) and particle size distribution (PSD) of mullite inclusions in different process conditions: (a) SEM of as-HIPed samples; (b) SEM of as-HEXed samples; (c) SEM of as-HIFed samples; (d) magnification SEM of as-HIPed samples; (e) magnification SEM of as-HEXed samples; (f) magnification SEM of as-HIFed samples; (g) PSD of as-HIPed samples; (h) PSD of as-HEXed samples; (i) PSD of as-HIFed samples

表 1 FGH96镍基粉末高温合金化学成分

Table 1. Chemical composition of nickel-based powder metallurgy superalloy FGH96

C Cr Co Mo W Al Ti Nb B Zr Ni 0.02~0.05 15.5~16.5 12.5~13.5 3.8~4.2 3.8~4.2 2.0~2.4 3.5~3.9 0.6~1.0 0.006~0.015 0.025~0.050 余量 表 2 夹杂物位置对试样低周疲劳性能的影响

Table 2. Effect of inclusion location on the low cycle fatigue properties of the specimen

试样编号 夹杂位置 循环周次 1 试样中心 52179 2 约1/2半径处 44121 3 试样边缘 4550 不含夹杂 — 60000(未断) -

[1] Reed R C. The Superalloys: Fundamentals and Applications. Cambridge: Cambridge University Press, 2006 [2] Fu H, Wang M Y, Ji Z, et al. Effect of thermal deformation on prior particle boundary of FGH96 superalloy. Powder Metall Technol, 2018, 36(3): 201 doi: 10.19591/j.cnki.cn11-1974/tf.2018.03.007傅豪, 王梦雅, 纪箴, 等. 热变形对FGH96高温合金原始颗粒边界的影响. 粉末冶金技术, 2018, 36(3): 201 doi: 10.19591/j.cnki.cn11-1974/tf.2018.03.007 [3] Wang M Y, Ji Z, Zhang Y F, et al. Research progress on the prior particle boundary of a powder metallurgy superalloy. Powder Metall Technol, 2017, 35(2): 142 doi: 10.3969/j.issn.1001-3784.2017.02.011王梦雅, 纪箴, 张一帆, 等. 粉末高温合金中原始粉末颗粒边界研究进展. 粉末冶金技术, 2017, 35(2): 142 doi: 10.3969/j.issn.1001-3784.2017.02.011 [4] Zhou L, Wang Y, Zou J W. Effect of carbon content on the microstructure and mechanical properties of powder metallurgy superalloy FGH96. Powder Metall Technol, 2017, 35(1): 46 doi: 10.3969/j.issn.1001-3784.2017.01.008周磊, 汪煜, 邹金文. C元素对FGH96粉末高温合金显微组织和力学性能的影响. 粉末冶金技术, 2017, 35(1): 46 doi: 10.3969/j.issn.1001-3784.2017.01.008 [5] Zou J W, Wang W X. Characteristic and quality control of inclusions in P/M superalloy. Powder Metall Technol, 2001, 19(1): 7 doi: 10.3321/j.issn:1001-3784.2001.01.002邹金文, 汪武祥. 粉末高温合金中夹杂物特性及其质量控制. 粉末冶金技术, 2001, 19(1): 7 doi: 10.3321/j.issn:1001-3784.2001.01.002 [6] Xie X S, Zhang L N, Zhang M C, et al. Micro-mechanical behavior study of non-metallic inclusions in nickel-base P/M superalloy. Acta Metall Sin, 2002, 38(6): 635 doi: 10.3321/j.issn:0412-1961.2002.06.016谢锡善, 张丽娜, 张麦仓, 等. 镍基粉末高温合金中夹杂物的微观力学行为研究. 金属学报, 2002, 38(6): 635 doi: 10.3321/j.issn:0412-1961.2002.06.016 [7] Huron E S, Roth P G. The influence of inclusions on low cycle fatigue life in a P/M nickel-base disk superalloy // The Minerals, Metals and Materials Society. Warrendale, 1996: 359 [8] Guo W M, Wu J T, Feng D. Research on the inclusions in Ni-base superalloy FGH95 powder. Powder Metall Technol, 2001, 19(1): 3 doi: 10.3321/j.issn:1001-3784.2001.01.001国为民, 吴剑涛, 冯涤. 镍基高温合金粉末中夹杂的研究. 粉末冶金技术, 2001, 19(1): 3 doi: 10.3321/j.issn:1001-3784.2001.01.001 [9] Zhou X M, Wang W X, Yang H T, et al. Character of artificial non-metallic inclusions in HIPed FGH96 alloy. J Aeronaut Mater, 2005, 25(4): 1 doi: 10.3969/j.issn.1005-5053.2005.04.001周晓明, 汪武祥, 杨洪涛, 等. HIP态FGH96合金中人工加入非金属夹杂物的特征. 航空材料学报, 2005, 25(4): 1 doi: 10.3969/j.issn.1005-5053.2005.04.001 [10] Zhou X M, Wang D L, Wang Y, et al. Deformation behavior of non-metallic inclusions in nickel-base P/M superalloy. Fail Anal Prev, 2008, 3(3): 23 doi: 10.3969/j.issn.1673-6214.2008.03.005周晓明, 汪殿龙, 汪煜, 等. 非金属夹杂物在镍基粉末高温合金中的变形行为. 失效分析与预防, 2008, 3(3): 23 doi: 10.3969/j.issn.1673-6214.2008.03.005 [11] Zeng Y P, Zhang M C, Dong J X, et al. Study on crack initiation and propagation induced by inclusion in nickel-base P/M superalloy. J Mater Eng, 2005(3): 10 doi: 10.3969/j.issn.1001-4381.2005.03.003曾燕屏, 张麦仓, 董建新, 等. 镍基粉末高温合金中夹杂物导致裂纹萌生和扩展行为的研究. 材料工程, 2005(3): 10 doi: 10.3969/j.issn.1001-4381.2005.03.003 [12] Zeng Y P, Dong J X, Zhang M C, et al. Behavior of inclusions in nickel-base P/M superalloy under tensile load. J Univ Sci Technol Beijing, 2005, 27(2): 202 doi: 10.3321/j.issn:1001-053X.2005.02.017曾燕屏, 董建新, 张麦仓, 等. 拉伸载荷下镍基粉末高温合金中夹杂物行为. 北京科技大学学报, 2005, 27(2): 202 doi: 10.3321/j.issn:1001-053X.2005.02.017 [13] Xu J, Xu Y M, Liu X L, et al. Inclusion effect on crack initiation of powder metallurgy superalloy. J Northwestern Polytech Univ, 2017, 35(Suppl): 108 https://www.cnki.com.cn/Article/CJFDTOTAL-XBGD2017S1019.htm许捷, 徐元铭, 刘新灵, 等. 夹杂物对粉末高温合金材料裂纹萌生的影响. 西北工业大学学报, 2017, 35(增刊): 108 https://www.cnki.com.cn/Article/CJFDTOTAL-XBGD2017S1019.htm [14] Hu D Y, Wang T, Ma Q H, et al. Effect of inclusions on low cycle fatigue lifetime in a powder metallurgy nickel-based superalloy FGH96. Int J Fatigue, 2019, 118: 23 [15] Naragani D, Sangid M D, Shade P A, et al. Investigation of fatigue crack initiation from a non-metallic inclusion via high energy X-ray diffraction microscopy. Acta Mater, 2017, 137: 71 doi: 10.1016/j.actamat.2017.07.027 -

下载:

下载: