-

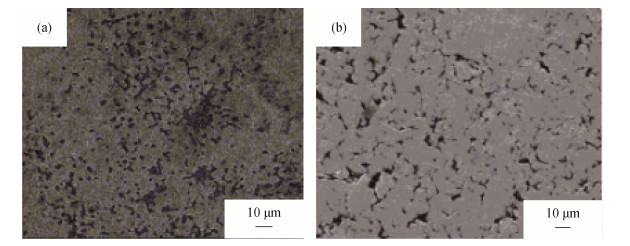

摘要: 通过热压烧结制备了含不同质量分数润滑剂(0%、10% MoS2、5% MoS2+5% BN和10% BN)的镍基材料,利用销盘摩擦磨损试验机对4种镍基材料在载荷30~60 N、滑动速度0.35~0.58 m·s-1(300~500 r·m-1)条件下进行摩擦磨损实验,通过扫描电镜观察磨损表面形貌,分析了不同润滑剂对镍基材料抗磨损性能的影响。结果表明:由于MoS2与基体之间结合良好,含有10% MoS2润滑剂的镍基材料具有较低且平稳的摩擦系数和最低的磨损率;由于BN与基体之间结合松散,含10% BN润滑剂的镍基材料在较高载荷和滑动速率下具有相对较高的摩擦系数和磨损率。Abstract: The nickel-based materials added with the different solid lubrications in the mass fraction as 0%, 10%MoS2, 5%MoS2+5%BN, and 10%BN were prepared by hot press sintering, respectively. The friction and wear properties of nickel-based composites were tested by pin disc friction and wear testing machine at the load of 30~60 N in the sliding speed of 0.35~0.58 m·s-1 (300~500 r·m-1), the wear surface morphology of Ni-based materials were observed by scanning electron microscopy (SEM), and the effects of different solid lubrications on the wear resistance of nickel-based materials were studied. The experimental results indicate that, the nickel-based composites with 10%MoS2 show the lower and stable friction coefficients and the lowest wear rates due to the good combination between MoS2 and matrix; however, the composites with 10%BN show the relatively high friction coefficients and wear rates under high load and sliding rate due to the loose combination between BN and matrix.

-

Key words:

- nickel-based materials /

- BN /

- MoS2 /

- wear rate /

- friction coefficient

-

表 1 镍基摩擦材料及润滑剂的物理参数

Table 1. Physical parameters of the Ni-based composites and solid lubricants

试样 粒度/ µm 纯度/ % 基体材料(80%Ni+20%Cr) 75.0 99.8 MoS2 30.0 99.0 BN 0.7~11.4 99.0 -

[1] Liu F, Jia J H, Yi G W, et al. Mechanical and tribological properties of NiCr–Al2O3 composites at elevated temperatures. Tribol Int, 2015, 84: 1 doi: 10.1016/j.triboint.2014.11.023 [2] Liu F, Yi G W, Wang W Z, et al. The influence of SrSO4 on the tribological properties of NiCr–Al2O3 cermet at elevated temperatures. Ceram Int, 2014, 40(2): 2799 doi: 10.1016/j.ceramint.2013.10.035 [3] Liu F, Yi G W, Wang W Z, et al. Tribological properties of NiCr–Al2O3 cermet-based composites with addition of multiple-lubricants at elevated temperatures. Tribol Int, 2013, 67: 164 doi: 10.1016/j.triboint.2013.07.017 [4] Liu E Y, Wang W Z, Gao Y M, et al. Tribological properties of Ni-based self-lubricating composites with addition of silver and molybdenum disulfide. Tribol Int, 2013, 57: 235 doi: 10.1016/j.triboint.2012.08.014 [5] Tyagi R, Xiong D S, Li J L, et al. Elevated temperature tribological behavior of Ni based composites containing nano-silver and hBN. Wear, 2010, 269(11-12): 884 doi: 10.1016/j.wear.2010.08.022 [6] Li J L, Xiong D S, Huo M F. Friction and wear properties of Ni–Cr–W–Al–Ti–MoS2 at elevated temperatures and self-consumption phenomena. Wear, 2008, 265(3-4): 566 doi: 10.1016/j.wear.2007.11.024 [7] Xiong D S. Lubrication behavior of Ni–Cr-based alloys containing MoS2 at high temperature. Wear, 2001, 251: 1094 doi: 10.1016/S0043-1648(01)00803-1 [8] Li J L, Xiong D S. Tribological properties of nickel-based self-lubricating composite at elevated temperature and counterface material selection. Wear, 2008, 265(3-4): 533 doi: 10.1016/j.wear.2007.09.005 [9] Mahathanabodee S, Palathai T, Raadnui S, et al. Dry sliding wear behavior of SS316L composites containing h-BN and MoS2 solid lubricants. Wear, 2014, 316: 37 doi: 10.1016/j.wear.2014.04.015 [10] Shi X L, Yao J, Xu Z S, et al. Tribological performance of TiAl matrix self-lubricating composites containing Ag, Ti3SiC2 and BaF2/CaF2 tested from room temperature to 600 ℃. Mater Des, 2014, 53: 620 doi: 10.1016/j.matdes.2013.07.053 [11] Shi X L, Song S Y, Zhai W Z, et al. Tribological behavior of Ni3Al matrix self-lubricating composites containing WS2, Ag and hBN tested from room temperature to 800 ℃. Mater Des, 2014, 55: 75 doi: 10.1016/j.matdes.2013.09.051 [12] Kong L Q, Zhu S Y, Qiao Z H, et al. Effect of Mo and Ag on the friction and wear behavior of ZrO2(Y2O3)–Ag–CaF2–Mo composites from 20 ℃ to 1000 ℃. Tribol Int, 2014, 78: 7 doi: 10.1016/j.triboint.2014.04.032 [13] Xiong D S. Lubrication behavior of Ni–Cr-based alloys containing MoS2 at high temperature. Wear, 2001, 251: 1094 doi: 10.1016/S0043-1648(01)00803-1 [14] Yang S L. The Research on Ni-based Materials with High Strength and Continuous Self-lubricating Performance in Wide Temoerature Range [Dissertation]. Lanzhou: Lanzhou University of Technology, 2017杨素兰. 宽温域内具有高强度和连续自润滑性能的镍基材料的研究[学位论文]. 兰州: 兰州理工大学, 2017 [15] Zhang H L. Preparation and Properities Research of Ni-based High Temperature Self-lubrication Composites[Dissertation]. Shenyang: Northeastern University, 2014张洪龙. 镍基高温复合自润滑材料的制备及性能研究[学位论文]. 沈阳: 东北大学, 2014 [16] Wei S M, Wang R C, Li Q Y, et al. Effect of BM on sintering properties of Ni-based abradable seal alloy. Rare Met Mater Eng, 2006, 35(1): 127 doi: 10.3321/j.issn:1002-185X.2006.01.032魏圣明, 王日初, 李庆勇, 等. BN对镍基可磨耗密封材料烧结性能的影响. 稀有金属材料与工程, 2006, 35(1): 127 doi: 10.3321/j.issn:1002-185X.2006.01.032 -

下载:

下载: