Optimum structure design of free-fall nozzle in preparation process of superalloy powders by electrode induction gas atomization technology

-

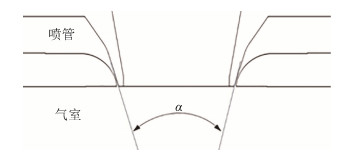

摘要: 采用电极感应熔化气雾化制粉法(electrode induction gas atomization,EIGA)制备粉末过程中,非限制式喷嘴的结构设计直接决定气雾化粉末的质量;非限制式喷嘴结构中不合理的喷射角度常常会引起反喷、片状粉、细粉收率低等问题,严重影响粉末的生产效率和质量。采用商业计算流体动力学(computational fluid dynamics,CFD)软件Fluent,以自主设计的第三代EIGA制备高温合金粉末装置中非限制式喷嘴为研究对象进行数值模拟建模,对带有气体回流区的非限制式喷嘴在熔体初次雾化过程中,喷射角度对反喷现象的影响以及反喷产生的机理进行了研究。结果表明,非限制式喷嘴射流角度过大时,熔体液滴会出现明显反喷现象;当非限制式喷嘴射流角度过小时,熔体液流雾化前过热度不足,生产的粉末球形度较差。因此,在优化设计非限制式喷嘴时,要应尽量控制气体回流区位置低于非限制式喷嘴熔体入口位置,保证合金熔体的过热度,同时防止反喷等现象。

-

关键词:

- 电极感应熔化气雾化技术 /

- 高温合金粉末 /

- 非限制式喷嘴结构 /

- 喷射角度 /

- 计算流体动力学

Abstract: The structure design of free-fall nozzle directly determines the quality of gas-atomized powders in electrode induction melting gas atomization (EIGA) process, the unreasonable jet angle in free-fall nozzle structure often causes the regurgitation phenomenon, the flake powders, and the low yield of fine powders, which seriously affect the production efficiency and quality of powders. The numerical modeling of free-fall nozzle structure in the self-designed third generation of EIGA superalloy powder preparation device was established using Fluent commercial software for computational fluid dynamics (CFD). The effect of jet angle on the regurgitation phenomenon and the regurgitation mechanism of free-fall nozzle with gas flow recirculation were investigated in the initial atomization of melt. In the results, when the jet angle of free-fall nozzle is too large, there is an obvious regurgitation phenomenon; when the jet angle is too small, the superheat of the melt stream before atomization is insufficient, resulting in the poor sphericity of produced powders. Therefore, to ensure the superheat of melt flow and prevent the regurgitation phenomenon, it is necessary to control the recirculation zone position of gas flow to be lower than the melt inlet position of free-fall nozzle. -

表 1 某牌号镍基高温合金熔体参数表[10]

Table 1. Physical properties of a certain Ni-based superalloy

热容/[J·(kg·K)-1] 热导率/[W·(m·K)-1] 黏度/(mPa·s) 表面张力/(mN·m-1) 密度/(kg·m-3) 720 29.6 0.05 1.84 7705 表 2 氩气物理参数

Table 2. Physical properties of Ar gas

密度/(kg·m-3) 黏度/(mPa·s) 热导率/[W·(m·K)-1] 热容/[J·(kg·K)-1] ideal-gas sutherland 0.0158 520.64 表 3 雾化模拟和实验工艺参数

Table 3. Simulated and experimental parameters in EIGA process

合金类型 合金液流直径/mm 进气口压力/MPa 喷嘴类型 镍基高温合金 4 4 非限制式环缝喷嘴 表 4 非限制式喷嘴不同气体喷射角度下回流区参数

Table 4. Parameters in the recirculation area of gas flow for the free-fall nozzle in different spray angles

喷射角度/(°) 气体交点位置X轴向坐标/mm 轴向X轴范围/mm 径向Y轴范围/mm 回流区宽/mm 回流区最大速度/(m·s-1) 30 142 146~169 -9~9 18 99 35 146 148.0~175.5 -11~11 22 140 40 143 146~203 -15~15 30 180 45 146 148~180 -16.5~16.5 33 215 -

[1] Guo W M, Zhao M H, Dong J X, et al. Research and development in FGH95 P/M nickel based superalloy. J Mech Eng, 2013, 49(18): 38 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201318006.htm国为民, 赵明汉, 董建新, 等. FGH95镍基粉末高温合金的研究和展望. 机械工程学报, 2013, 49(18): 38 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201318006.htm [2] Zou J W, Wang W X. Development and application of P/M superalloy. J Aeronaut Mater, 2006, 26(3): 244 doi: 10.3969/j.issn.1005-5053.2006.03.051邹金文, 汪武祥. 粉末高温合金研究进展与应用. 航空材料学报, 2006, 26(3): 244 doi: 10.3969/j.issn.1005-5053.2006.03.051 [3] Zhang G X, Han S B, Sun Z K. Effects of thermal induced porosity on mechanical properties of PM superalloy. Powder Metall Ind, 2015, 25(1): 42 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201501015.htm张国星, 韩寿波, 孙志坤. 热诱导孔洞对粉末冶金高温合金性能的影响. 粉末冶金工业, 2015, 25(1): 42 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201501015.htm [4] Zhang L N, Zhang M C, Li X, et al. Progress in study of nonmetallic inclusion in powder metallurgy (P/M) superalloys. Ordn Mater Sci Eng, 2001, 24(3): 64 doi: 10.3969/j.issn.1004-244X.2001.03.018张丽娜, 张麦仓, 李晓, 等. 粉末高温合金中非金属夹杂物问题的研究进展. 兵器材料科学与工程, 2001, 24(3): 64 doi: 10.3969/j.issn.1004-244X.2001.03.018 [5] Zhang Y W, Yang S Z, Li L, et al. Current status of research on PM superalloy in China. Mater Rev, 2002, 16(5): 1 doi: 10.3321/j.issn:1005-023X.2002.05.001张义文, 杨士仲, 李力, 等. 我国粉末高温合金的研究现状. 材料导报, 2002, 16(5): 1 doi: 10.3321/j.issn:1005-023X.2002.05.001 [6] He G A, Ding H H, Liu C Z, et al. Effects of powder characteristics on microstructure and deformation activation energy of nickel based superalloy. Chin J Nonferrous Met, 2016, 26(1): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201601006.htm何国爱, 丁晗晖, 刘琛仄, 等. 粉末特性对镍基粉末冶金高温合金组织及热变形行为的影响. 中国有色金属学报, 2016, 26(1): 37 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201601006.htm [7] Ahsan M N, Pinkerton A J, Moat R J, et al. A comparative study of laser direct metal deposition characteristics using gas and plasma-atomized Ti–6Al–4V powders. Mater Sci Eng A, 2011, 528(25-26): 7648 doi: 10.1016/j.msea.2011.06.074 [8] Lu L L, Liu X F, Zhang S M, et al. A combinatorial technique incorporating high frequency inductive heating and gas atomization for preparing spherical titanium powders from titanium wires. Mater Rep, 2018, 32(8): 1267 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201808012.htm陆亮亮, 刘雪峰, 张少明, 等. 高频感应熔化金属丝气雾化制备球形钛粉. 材料导报, 2018, 32(8): 1267 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201808012.htm [9] Yuan H, Li Z, Xu W Y, et al. The study of argon atomized superalloy powders. Powder Metall Ind, 2010, 20(4): 1 doi: 10.3969/j.issn.1006-6543.2010.04.001袁华, 李周, 许文勇, 等. 氩气雾化制备高温合金粉末的研究. 粉末冶金工业, 2010, 20(4): 1 doi: 10.3969/j.issn.1006-6543.2010.04.001 [10] Liu Y, Li Z, Zhang G Q, et al. Flow field of double layer atomizer. J Aeronaut Mater, 2015, 35(5): 63 https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201505012.htm刘杨, 李周, 张国庆, 等. 双层雾化器流场的模拟研究. 航空材料学报, 2015, 35(5): 63 https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201505012.htm [11] Han Z Y, Ceng G, Liang S J, et al. Development in powder production technology of Ni-based superalloy. Mater China, 2014, 32(12): 748 https://www.cnki.com.cn/Article/CJFDTOTAL-XJKB201412006.htm韩志宇, 曾光, 梁书锦, 等. 镍基高温合金粉末制备技术的发展现状. 中国材料进展, 2014, 32(12): 748 https://www.cnki.com.cn/Article/CJFDTOTAL-XJKB201412006.htm [12] Jia C L, Ge C C, Yan Q Z. Innovative technologies for powder metallurgy-based disk superalloys: Progress and proposal. Chin Phys B, 2016, 25(2): 320 doi: 10.1088/1674-1056/25/2/026103 [13] Ting J, Peretti M W, Eisen W B. The effect of wake-closure phenomenon on gas atomization performance. Mater Sci Eng A, 2002, 326(1): 110 doi: 10.1016/S0921-5093(01)01437-X [14] Motaman S, Mullis A M, Cochrane R F, et al. Numerical and experimental investigations of the effect of melt delivery nozzle design on the open- to closed-wake transition in closed-coupled gas atomization. Metall Mater Trans B, 2015, 46(4): 1990 doi: 10.1007/s11663-015-0346-6 [15] Ting J, Anderson I E. A computational fluid dynamics (CFD) investigation of the wake closure phenomenon. Mater Sci Eng A, 2004, 379(1): 264 http://www.sciencedirect.com/science/article/pii/S0921509304002254 [16] Zeoli N, Gu S. Numerical modelling of droplet break-up for gas atomisation. Comput Mater Sci, 2006, 38(2): 282 doi: 10.1016/j.commatsci.2006.02.012 [17] Zeoli N, Gu S. Computational simulation of metal droplet break-up, cooling and solidification during gas atomisation. Comput Mater Sci, 2008, 43(2): 268 doi: 10.1016/j.commatsci.2007.10.005 [18] Motaman S, Mullis A M, Cochrane R F, et al. Numerical and experimental modelling of back stream flow during close-coupled gas atomization. Comput Fluids, 2013, 88: 1 doi: 10.1016/j.compfluid.2013.08.006 [19] Zhao W J, Cao F Y, Ning Z L, et al. A computational fluid dynamics (CFD) investigation of the flow field and the primary atomization of the close coupled atomizer. Comput Chem Eng, 2012, 40: 58 doi: 10.1016/j.compchemeng.2012.02.014 [20] Fritsching U, Uhlenwinkel V. Hybrid gas atomization for powder production. [in] Powder Metallurgy. Eds by Kondoh K. Rijeka: In Tech, 2012 [21] Chen X. Study on Structure and Atomization Mechanism of Closely Coupling Gas Atomization[Dissertation]. Changsha: Central South University, 2007陈欣. 紧耦合气雾化流场结构和雾化机理研究[学位论文]. 长沙: 中南大学, 2007 [22] Fritsching U. Spray Simulation: Modeling and Numerical Simulation of Sprayforming Metals. New York: American Society of Mechanical Engineers, 2006 [23] Ashgriz N. Handbook of Atomization and Sprays. Boston: Springer, 2011 [24] Firmansyah D A, Kaiser R, Zahaf R, et al. Numerical simulations of supersonic gas atomization of liquid metal droplets. Jpn J Appl Phys, 2014, 53: 5S3 http://adsabs.harvard.edu/abs/2014JaJAP..53eHA09A [25] Aydin O, Unal R. Experimental and numerical modeling of the gas atomization nozzle for gas flow behavior. Comput Fluids, 2011, 42(1): 37 doi: 10.1016/j.compfluid.2010.10.013 -

下载:

下载: