| [1] |

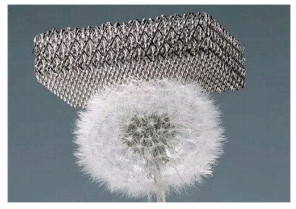

Scott. Boeing invented the lightest metal in history "99.99% are air". Electron Prod, 2015(11): 27 https://www.cnki.com.cn/Article/CJFDTOTAL-DZJR201511003.htmScott. 波音发明史上最轻金属"99.99%都是空气". 今日电子, 2015(11): 27 https://www.cnki.com.cn/Article/CJFDTOTAL-DZJR201511003.htm

|

| [2] |

Niu W J, Bai C G, Qiu G B, et al. Review on manufacture technique of foamed Ti and Ti alloys. Powder Metall Technol, 2009, 27(4): 301 http://pmt.ustb.edu.cn/article/id/fmyjjs200904014牛文娟, 白晨光, 邱贵宝, 等. 泡沫钛及其合金制备方法研究进展. 粉末冶金技术, 2009, 27(4): 301 http://pmt.ustb.edu.cn/article/id/fmyjjs200904014

|

| [3] |

Zhang S W. Foam metal research and application progress. Powder Metall Technol, 2016, 34(3): 222 doi: 10.3969/j.issn.1001-3784.2016.03.013张士卫. 泡沫金属的研究与应用进展. 粉末冶金技术, 2016, 34(3): 222 doi: 10.3969/j.issn.1001-3784.2016.03.013

|

| [4] |

Ashby M F, Evans A G, Fleck N A, et al. Metal Foams: A Design Guide. Amsterdam: Elsevier, 2000

|

| [5] |

Gibson L J, Ashby M F. Cellular Solids: Structure and Properties. Cambridge: Cambridge University Press, 1999

|

| [6] |

Liu B X, Zhong S W. Nickel foam production by electro-deposition. Nonferrous Met Sci Eng, 2011, 2(3): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-JXYS201103006.htm刘柏雄, 钟素文. 电沉积法制备泡沫镍的研究. 有色金属科学与工程, 2011, 2(3): 28 https://www.cnki.com.cn/Article/CJFDTOTAL-JXYS201103006.htm

|

| [7] |

Shi Y L, Guo Z M, Li X M, et al. 3D printing and gelcasting process of Ti-6Al-4V porous titanium bone. Powder Metall Ind, 2018, 28(3): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201803011.htm石永亮, 郭志猛, 李秀敏, 等. 3D打印-凝胶注模制备蜂窝状Ti-6Al-4V多孔钛骨骼的研究. 粉末冶金工业, 2018, 28(3): 34 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201803011.htm

|

| [8] |

Xiao J, Qiu G B. Research review of space holders of sintered titanium foams with large pores and high porosity. Mater China, 2018, 37(5): 372 https://www.cnki.com.cn/Article/CJFDTOTAL-XJKB201805007.htm肖健, 邱贵宝. 大孔径高孔隙率烧结泡沫钛的造孔剂研究述评. 中国材料进展, 2018, 37(5): 372 https://www.cnki.com.cn/Article/CJFDTOTAL-XJKB201805007.htm

|

| [9] |

Xiao J, Qiu G B. Research progress in preparation methods of titanium foams or porous titanium. Rare Met Mater Eng, 2017, 46(6): 1734 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201706050.htm肖健, 邱贵宝. 泡沫或多孔钛的制备方法研究进展. 稀有金属材料与工程, 2017, 46(6): 1734 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201706050.htm

|

| [10] |

Xiao J, Qiu G B, Liao Y L, et al. Effects of spacer size on pore structure of titanium foams. Rare Met Mater Eng, 2015, 44(10): 2583 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201510048.htm肖健, 邱贵宝, 廖益龙, 等. 造孔剂大小对泡沫钛孔隙结构的影响. 稀有金属材料与工程, 2015, 44(10): 2583 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201510048.htm

|

| [11] |

Xiao J, Qiu G B, Liao Y L, et al. Microstructure and mechanical properties of titanium foams prepared with carbamide as space holder. Rare Met Mater Eng, 2015, 44(7): 1724 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201507030.htm肖健, 邱贵宝, 廖益龙, 等. 尿素作为造孔剂制备泡沫钛的结构和力学性能. 稀有金属材料与工程, 2015, 44(7): 1724 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201507030.htm

|

| [12] |

Xiao J, Cui H, Qiu G B. Primary investigation on mechanical reproducibility of titanium foams. J Funct Mater, 2015, 46(22): 22015 doi: 10.3969/j.issn.1001-9731.2015.22.003肖健, 崔豪, 邱贵宝. 泡沫钛力学性能重复性初探. 功能材料, 2015, 46(22): 22015 doi: 10.3969/j.issn.1001-9731.2015.22.003

|

| [13] |

Xiao J, Yang Y, Qiu G B, et al. Volume change of macropores of titanium foams during sintering. Trans Nonferrous Met Soc China, 2015, 25(11): 3834 doi: 10.1016/S1003-6326(15)64029-8

|

| [14] |

Xiao J, Cui H, Qiu G B, et al. Investigation on relationship between porosity and spacer content of titanium foams. Mater Des, 2015, 88: 132 doi: 10.1016/j.matdes.2015.08.125

|

| [15] |

Wang X S, Lu Z L, Jia L, et al. Preparation and properties of low cost porous titanium by using rice husk as hold space. Prog Nat Sci, 2017, 27(3): 344 doi: 10.1016/j.pnsc.2017.04.014

|

| [16] |

Sharma M, Gupta G K, Modi O P, et al. Titanium foam through powder metallurgy route using acicular urea particles as space holder. Mater Lett, 2011, 65(21-22): 3199 doi: 10.1016/j.matlet.2011.07.004

|

| [17] |

Niu W J, Bai C G, Qiu G B, et al. Processing and properties of porous titanium using space holder technique. Mater Sci Eng A, 2009, 506(1-2): 148 doi: 10.1016/j.msea.2008.11.022

|

| [18] |

Dewidar M, Mohamed H F, Lim J K. A new approach for manufacturing a high porosity Ti-6Al-4V scaffolds for biomedical applications. J Mater Sci Technol, 2008, 24(6): 931

|

| [19] |

Smorygo O, Marukovich A, Mikutski V, et al. High-porosity titanium foams by powder coated space holder compaction method. Mater Lett, 2012, 83: 17 doi: 10.1016/j.matlet.2012.05.082

|

| [20] |

Lee B, Lee T, Lee Y, et al. Space-holder effect on designing pore structure and determining mechanical properties in porous titanium. Mater Des, 2014, 57: 712 doi: 10.1016/j.matdes.2013.12.078

|

| [21] |

Hosseini S A, Yazdani-Rad R, Kazemzadeh A, et al. A Comparative study on the mechanical behavior of porous titanium and NiTi produced by a space holder technique. J Mater Eng Perform, 2014, 23(3): 799 doi: 10.1007/s11665-013-0810-x

|

| [22] |

Tuncer N, Arslan G, Maire E, et al. Investigation of spacer size effect on architecture and mechanical properties of porous titanium. Mater Sci Eng A, 2011, 530(1): 633

|

| [23] |

Tuncer N, Arslan G. Designing compressive properties of titanium foams. J Mater Sci, 2009, 44(6): 1477 doi: 10.1007/s10853-008-3167-z

|

| [24] |

Arifvianto B, Leeflang M A, Zhou J. Diametral compression behavior of biomedical titanium scaffolds with open, interconnected pores prepared with the space holder method. J Mech Behav Biomed Mater, 2017, 68: 144 doi: 10.1016/j.jmbbm.2017.01.046

|

| [25] |

Arifvianto B, Leeflang M A, Zhou J. Characterization of the porous structures of the green body and sintered biomedical titanium scaffolds with micro-computed tomography. Mater Charact, 2016, 121: 48 doi: 10.1016/j.matchar.2016.09.026

|

| [26] |

Imwinkelried T. Mechanical properties of open-pore titanium foam. J Biomed Mater Res A, 2007, 81(4): 964

|

| [27] |

Jha N, Mondal D P, Majumdar J D, et al. Highly porous open cell Ti-foam using NaCl as temporary space holder through powder metallurgy route. Mater Des, 2013, 47: 810 doi: 10.1016/j.matdes.2013.01.005

|

| [28] |

Mansourighasri A, Muhamad N, Sulong A B. Processing titanium foams using tapioca starch as a space holder. J Mater Process Technol, 2012, 212(1): 83 doi: 10.1016/j.jmatprotec.2011.08.008

|

| [29] |

Xiao J, Liu J P, Liu X B, et al. Research progress in surface modification of foamed titanium. Mater Rep, 2019, 33(5): 1558 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201909020.htm肖健, 刘锦平, 刘先斌, 等. 泡沫钛表面改性研究进展. 材料导报, 2019, 33(5): 1558 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201909020.htm

|

| [30] |

Wang J Z. The 10th international conference on porous metal and metal foam (MetFoam 2017) was successfully held in Nanjing. Powder Metall Ind, 2017, 25(5): 79 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201705024.htm王建忠. 第10届多孔金属与金属泡沫国际会议在南京顺利召开. 粉末冶金工业, 2017, 25(5): 79 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201705024.htm

|

| [31] |

Esen Z, Bor Ş. Processing of titanium foams using magnesium spacer particles. Scr Mater, 2007, 56(5): 341 doi: 10.1016/j.scriptamat.2006.11.010

|

下载:

下载: