Research progress on preparation of biological implant materials by additive manufacturing

-

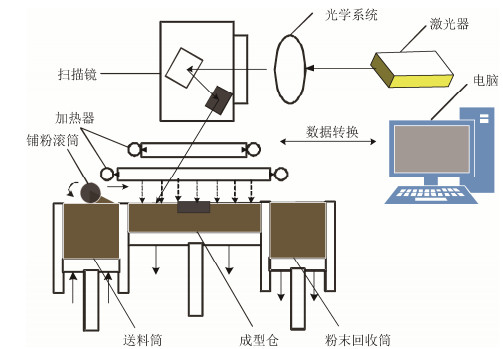

摘要: 增材制造技术突破了传统模具加工工艺的限制,可用于高效个性化定制生物医用材料。近年来,医学上对骨骼修复和移植的个性化需求显著增加,增材制造可满足该定制化的需求,促使增材制造技术在生物医用材料领域占据重要地位。随着材料科学技术和计算机辅助技术(CAD/CAM)的发展,可用于增材制造的生物植入材料不再局限于钛系、钽系、钴铬钼等合金,聚醚醚酮、磷酸钙盐等非金属类材料因良好的生物相容性也得到了广泛应用,增材制造技术制备仿生人造骨植入体成为新的研究热点。本文介绍了增材制造技术的原理,对激光、电子束、光固化等增材制造技术进行了比较,并阐述了增材制造在生物植入体和医疗器械方面的应用现状,对增材制造技术在医疗领域的应用及发展做了展望。Abstract: Additive manufacturing technology breaks through the limitations of traditional mold processing technology, and it is an important method for the efficiently customizing biomedical materials. Recently, the personalization needs of medical bone repair and transplantation have increased significantly. The customized and individualized advantages gradually promote the additive manufacturing technology to play an important role in the field of biomedical materials. With the development of materials science and computer aided technology (CAD/CAM), the biological implant materials used for additive manufacturing are no longer limited to the alloys such as titanium alloys, tantalum alloys, and vitallium. Because of good biocompatibility, the non-metal materials such as polyetheretherketone (PEEK) and calcium phosphate are widely used in biomaterials. The preparation of artificial bone implants by additive manufacturing technology has become a new research hotspot. The principle of additive manufacturing technology was reviewed, and the manufacturing techniques by laser, electron beam, and photocuring were compared in this paper. The application status of additive manufacturing in biological implants and medical devices was introduced, and the development prospects of additive manufacturing technology in medical field were prospected.

-

Key words:

- additive manufacturing /

- biomaterials /

- implants /

- research progress

-

表 1 增材制造技术工艺特点

Table 1. Characteristics of additive manufacturing technology

-

[1] Malik H H, Darwood A R, Shaunak S, et al. Three-dimensional printing in surgery: a review of current surgical applications. J Surg Res, 2015, 199(2): 512 doi: 10.1016/j.jss.2015.06.051 [2] Wang L, Dai K R. Individualized treatment of orthopaedics and 3D printing technology. J Med Biomech, 2014, 29(3): 193 https://www.cnki.com.cn/Article/CJFDTOTAL-YISX201403001.htm王燎, 戴尅戎. 骨科个体化治疗与3D打印技术. 医用生物力学, 2014, 29(3): 193 https://www.cnki.com.cn/Article/CJFDTOTAL-YISX201403001.htm [3] Han Q Y, Li S P, Xiao X F, et al. 3D printing: The application in medicine devices. Sci Technol Rev, 2017, 35(2): 72 https://www.cnki.com.cn/Article/CJFDTOTAL-KJDB201702018.htm韩倩宜, 李淑萍, 肖雄夫, 等. 3D打印技术在植入式医疗器械中的应用. 科技导报, 2017, 35(2): 72 https://www.cnki.com.cn/Article/CJFDTOTAL-KJDB201702018.htm [4] Shi Y S, Yan C Z, Wei Q S, et al. Polymer based composites for selective laser sintering 3D printing technology. Sci China Inf Sci, 2015, 45(2): 204 https://www.cnki.com.cn/Article/CJFDTOTAL-PZKX201502004.htm史玉升, 闫春泽, 魏青松, 等. 选择性激光烧结3D打印用高分子复合材料. 中国科学(信息科学), 2015, 45(2): 204 https://www.cnki.com.cn/Article/CJFDTOTAL-PZKX201502004.htm [5] Scalera F, Corcione C E, Montagna F, et al. Development and characterization of UV curable epoxy/hydroxyapatite suspensions for stereolithography applied to bone tissue engineering. Ceram Int, 2014, 40(10): 15455 doi: 10.1016/j.ceramint.2014.06.117 [6] Wang H J, Cui Z W, Sun F, et al. Superalloy GH4169 complicated components prepared by selective laser melting forming technique. Powder Metall Technol, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009王会杰, 崔照雯, 孙峰, 等. 激光选区熔化成形技术制备高温合金GH4169复杂构件. 粉末冶金技术, 2016, 34(5): 368 doi: 10.3969/j.issn.1001-3784.2016.05.009 [7] Wu H, Ren J Y, Huang Q L, et al. Effect of laser parameters on microstructure, metallurgical defects and property of AlSi10Mg printed by selective laser melting. J Micromech Mol Phys, 2017, 2(4): 5 doi: 10.1142/S2424913017500175 [8] He C L, Tang Z H, Tian H Y, et al. Progress in the development of biomedical polymer materials fabricated by 3-dimensional printing technology. Acta Polym Sin, 2013(6): 722 https://www.cnki.com.cn/Article/CJFDTOTAL-GFXB201306003.htm贺超良, 汤朝晖, 田华雨, 等. 3D打印技术制备生物医用高分子材料的研究进展. 高分子学报, 2013(6): 722 https://www.cnki.com.cn/Article/CJFDTOTAL-GFXB201306003.htm [9] Liu C, Kong X J, Wu S W, et al. Research on powder injection molding of Ti6Al4V alloys for biomedical application. Powder Metall Technol, 2018, 36(3): 217 doi: 10.19591/j.cnki.cn11-1974/tf.2018.03.010刘超, 孔祥吉, 吴胜文, 等. 生物医用Ti6Al4V合金粉末注射成形工艺研究. 粉末冶金技术, 2018, 36(3): 217 doi: 10.19591/j.cnki.cn11-1974/tf.2018.03.010 [10] Zhou Y L, Niinomi M, Akahori T, et al. Corrosion resistance and biocompatibility of Ti–Ta alloys for biomedical applications. Mater Sci Eng A, 2005, 398(1): 28 http://www.sciencedirect.com/science/article/pii/S0921509305002133 [11] Kopova I, Stráský J, Harcuba P, et al. Newly developed Ti–Nb–Zr–Ta–Si–Fe biomedical beta titanium alloys with increased strength and enhanced biocompatibility. Mater Sci Eng C, 2016, 60: 230 doi: 10.1016/j.msec.2015.11.043 [12] Shi F W, Fu J, Guo Z. The application of 3D printing technique in the oncology teaching of orthopedics. Chin J Med Educ, 2015, 35(6): 916 doi: 10.3760/cma.j.issn.1673-677X.2015.06.033施凤伟, 付军, 郭征. 3D打印技术在骨科学肿瘤教学中的应用. 中华医学教育杂志, 2015, 35(6): 916 doi: 10.3760/cma.j.issn.1673-677X.2015.06.033 [13] Yang J, Cai H, Lü J, et al. In vivo study of a self-stabilizing artificial vertebral body fabricated by electron beam melting. Spine, 2014, 39(8): 486 doi: 10.1097/BRS.0000000000000211 [14] Hu H B, Liu H Q, Wang J E, et al. Research progress of biomedical porous titanium and its alloys. Mater Rev, 2012, 26(19): 262 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2012S1077.htm胡海波, 刘会群, 王杰恩, 等. 生物医用多孔钛及钛合金的研究进展. 材料导报, 2012, 26(19): 262 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2012S1077.htm [15] Liu C, Kong X J, Wu S W, et al. Research progress on metal injection molding of titanium and titanium alloys. Powder Metall Technol, 2017, 35(2): 150 doi: 10.3969/j.issn.1001-3784.2017.02.012刘超, 孔祥吉, 吴胜文, 等. 钛及钛合金金属粉末注射成形技术的研究进展. 粉末冶金技术, 2017, 35(2): 150 doi: 10.3969/j.issn.1001-3784.2017.02.012 [16] Li S J, Li X K, Hou W T, et al. Fabrication of open-cellular (porous) titanium alloy implants: osseointegration, vascularization and preliminary human trials. Sci China Mater, 2018, 61(4): 525 doi: 10.1007/s40843-017-9063-6 [17] Palmquist A, Snis A, Emanuelsson L, et al. Long-term biocompatibility and osseointegration of electron beam melted, free-form-fabricated solid and porous titanium alloy: experimental studies in sheep. J Biomater Appl, 2013, 27(8): 1003 doi: 10.1177/0885328211431857 [18] Shivaram A, Bose S, Bandyopadhyay A. Understanding long-term silver release from surface modified porous titanium implants. Acta Biomater, 2017, 58: 550 doi: 10.1016/j.actbio.2017.05.048 [19] Taniguchi N, Fujibayashi S, Takemoto M, et al. Effect of pore size on bone ingrowth into porous titanium implants fabricated by additive manufacturing: An in vivo experiment. Mater Sci Eng C, 2016, 59: 690 doi: 10.1016/j.msec.2015.10.069 [20] Wauthle R, Ahmadi S M, Yavari S A, et al. Revival of pure titanium for dynamically loaded porous implants using additive manufacturing. Mater Sci Eng C, 2015, 54: 94 doi: 10.1016/j.msec.2015.05.001 [21] Butscher A, Bohner M, Hofmann S, et al. Structural and material approaches to bone tissue engineering in powder-based three-dimensional printing. Acta Biomater, 2011, 7(3): 907 doi: 10.1016/j.actbio.2010.09.039 [22] Yang G Y, Tang H P, Liu N, et al. Fabrication and characterization of Ti-5Ta-30Nb-7Zr biomedical porous alloy by selective electron beam melting. Titanium Ind Prog, 2017, 34(1): 33 https://www.cnki.com.cn/Article/CJFDTOTAL-TGYJ201701010.htm杨广宇, 汤慧萍, 刘楠, 等. Ti-5Ta-30Nb-7Zr合金医用多孔材料的电子束选区熔化成形及表征. 钛工业进展, 2017, 34(1): 33 https://www.cnki.com.cn/Article/CJFDTOTAL-TGYJ201701010.htm [23] Wauthle R, van der Stok J, Yavari S A, et al. Additively manufactured porous tantalum implants. Acta Biomater, 2015, 14: 217 doi: 10.1016/j.actbio.2014.12.003 [24] Balla V K, Bodhak S, Bose S, et al. Porous tantalum structures for bone implants: Fabrication, mechanical and in vitro biological properties. Acta Biomater, 2010, 6(8): 3349 doi: 10.1016/j.actbio.2010.01.046 [25] Jie F X, He X M, Yu J H, et al. Structural characteristics and mechanical behavior of selective laser sintered porous Ti-6Mo alloy for biomedical applications. Rare Met Mater Eng, 2016, 44(6): 1477 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201606014.htm颉芳霞, 何雪明, 俞经虎, 等. 生物医用多孔Ti-6Mo合金选择性激光烧结的结构特征和力学行为. 稀有金属材料与工程, 2016, 45(6): 1477 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE201606014.htm [26] Lin H, Yang Y Q, Zhang G Q, et al. Tribological performance of medical CoCrMo alloy fabricated by selective laser melting. Acta Opt Sin, 2016(11): 1114003-1 https://www.cnki.com.cn/Article/CJFDTOTAL-GXXB201611019.htm林辉, 杨永强, 张国庆, 等. 激光选区熔化医用钴铬钼合金的摩擦性能. 光学学报, 2016, 36(11): 1114003-1 https://www.cnki.com.cn/Article/CJFDTOTAL-GXXB201611019.htm [27] Schwindling F S, Seubert M, Rues S, et al. Two-body wear of CoCr fabricated by selective laser melting compared with different dental alloys. Tribol Lett, 2015, 60(2): 25 doi: 10.1007/s11249-015-0601-7 [28] Zhang G Q, Yang Y Q, Lin H, et al. Study on tribology performance of CoCrMo alloy parts manufactured by selective laser melting. Chin J Lasers, 2016, 43(8): 167 https://www.cnki.com.cn/Article/CJFDTOTAL-JJZZ201608023.htm张国庆, 杨永强, 林辉, 等. 激光选区熔化成型CoCrMo合金摩擦学性能研究. 中国激光, 2016, 43(8): 167 https://www.cnki.com.cn/Article/CJFDTOTAL-JJZZ201608023.htm [29] Chiba A, Kumagai K, Nomura N, et al. Pin-on-disk wear behavior in a like-on-like configuration in a biological environment of high carbon cast and low carbon forged Co–29Cr–6Mo alloys. Acta Mater, 2007, 55(4): 1309 doi: 10.1016/j.actamat.2006.10.005 [30] Yu Q, Tian J. Application of three-dimensional printing technique in manufacturing scaffolds for bone tissue engineering. J Clin Rehabil Tissue Eng Res, 2015, 19(30): 4870 doi: 10.3969/j.issn.2095-4344.2015.30.022于强, 田京. 构建骨组织工程支架中应用的3D打印技术. 中国组织工程研究, 2015, 19(30): 4870 doi: 10.3969/j.issn.2095-4344.2015.30.022 [31] Cao X. Research of Biomimetic Preparation and Characterization of Hydroxyap Coating on Titanium Matrix Surface[Dissertation]. Xi'an: Shaanxi University of Science and Technology, 2015曹鑫. 钛基羟基磷灰石涂层的仿生制备与性能研究[学位论文]. 西安: 陕西科技大学, 2015 [32] Warnke P H, Seitz H, Warnke F, et al. Ceramic scaffolds produced by computer-assisted 3D printing and sintering: Characterization and biocompatibility investigations. J Biomed Mater Res B, 2010, 93(1): 212 http://www.ncbi.nlm.nih.gov/pubmed/20091914 [33] Zhuang J Y. Study on Preparation of TCP Scaffold via Selective Laser Sintering[Dissertation]. Changsha: Central South University, 2013庄静宇. 选择性激光烧结制备磷酸三钙人工骨支架的研究[学位论文]. 长沙: 中南大学, 2013 [34] Saijo H, Igawa K, Kanno Y, et al. Maxillofacial reconstruction using custom-made artificial bones fabricated by inkjet printing technology. J Artif Organs, 2009, 12(3): 200 doi: 10.1007/s10047-009-0462-7 [35] Lian Q, Zhuang P, Li C H, et al. Mechanical properties of polylactic acid/β-tricalcium phosphate composite scaffold with double channels based on three-dimensional printing technique. Chin J Rep Reconstr Surg, 2014, 28(3): 309 https://www.cnki.com.cn/Article/CJFDTOTAL-ZXCW201403014.htm连芩, 庄佩, 李常海, 等. 3D打印双管道聚乳酸/β-磷酸三钙生物陶瓷复合材料支架的力学性能研究. 中国修复重建外科杂志, 2014, 28(3): 309 https://www.cnki.com.cn/Article/CJFDTOTAL-ZXCW201403014.htm [36] Zou L M, Yang C, Li Y Y. Research progress on preparing Ti-based biomedical materials by powder metallurgy. Mater Rev, 2011, 25(15): 82 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201115019.htm邹黎明, 杨超, 李元元. 粉末冶金法制备钛基生物医学材料的研究进展. 材料导报, 2011, 25(15): 82 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201115019.htm [37] Li X, Feng C D, Wang L, et al. Fabrication and in vitro biocompatibility of porous Ti/chitason/hydroxyapatite composite scaffold. Chin J Orthop Trauma, 2016, 18(1): 6 doi: 10.3760/cma.j.issn.1671-7600.2016.01.002李祥, 冯辰栋, 王林, 等. 3D打印多孔钛/壳聚糖/羟基磷灰石复合支架的制备与体外生物相容性研究. 中华创伤骨科杂志, 2016, 18(1): 6 doi: 10.3760/cma.j.issn.1671-7600.2016.01.002 [38] Song J, Wang S, Liao Z H, et al. The research progress offriction and wear properties of polyetheretherketone and its modified materials for artificial joints. J Funct Mater, 2014, 45(23): 23010 doi: 10.3969/j.issn.1001-9731.2014.23.002宋剑, 王松, 廖振华, 等. 聚醚醚酮及其改性的人工关节材料的摩擦磨损性能研究进展. 功能材料, 2014, 45(23): 23010 doi: 10.3969/j.issn.1001-9731.2014.23.002 [39] Zhang Y. Thermodynamic Simulation and Experiment of 3D Printing of Bionic Artificial Bone with Polyetheretherketone (PEEK)[Dissertation]. Changchun: Jilin University, 2014张钰. 聚醚醚酮仿生人工骨3D打印热力学仿真及实验研究[学位论文]. 长春: 吉林大学, 2014 [40] Tan L X, Liu Y X, Chen R M, et al. Multi-point flexible molding for personalized PEEK skull repair. J Xi'an Jiaotong Univ, 2016, 50(8): 130 https://www.cnki.com.cn/Article/CJFDTOTAL-XAJT201608021.htm谭力新, 刘亚雄, 陈若梦, 等. 个性化聚醚醚酮颅骨植入物多点柔性注塑工艺. 西安交通大学学报, 2016, 50(8): 130 https://www.cnki.com.cn/Article/CJFDTOTAL-XAJT201608021.htm [41] Yunnan Daxue Bao. The world's first 3D printed PEEK implant for the treatment of nutcracker syndrome was completed successfully by Yunnan University and Air Force Military Medical University[J/OL]. Yunnan Daxue Bao (2018-03-07)[2018-07-18]. http://ynunews.cuepa.cn/show_more.php?doc_id=2381274云南大学报. 云南大学联合空军军医大学成功实现世界首例3D打印PEEK植入体用于胡桃夹综合症治疗[J/OL]. 云南大学报(2018-03-07)[2018-07-18]. http://ynunews.cuepa.cn/show_more.php?doc_id=2381274 [42] Yang C C, Tian X Y, Li D C, et al. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J Mater Process Technol, 2017, 248: 1 doi: 10.1016/j.jmatprotec.2017.04.027 [43] Wang J, Huang H, Wang S Y, et al. Shoulder hemiarthroplasty assisted by individualized navigation templates 3D printed. Chin J Orthop Trauma, 2017, 19(7): 596 doi: 10.3760/cma.j.issn.1671-7600.2017.07.008王均, 黄河, 王少云, 等. 3D打印个体化导航模板辅助半肩置换的有效性和精确性. 中华创伤骨科杂志, 2017, 19(7): 596 doi: 10.3760/cma.j.issn.1671-7600.2017.07.008 [44] Liu F Z, Liu M X, Wang Y H, et al. Research progress on application of 3D printing technology in medical field. Mater China, 2016, 35(5): 381 https://www.cnki.com.cn/Article/CJFDTOTAL-XJKB201605008.htm刘凤珍, 刘明信, 王运华, 等. 3D打印技术在医学领域中的应用研究进展. 中国材料进展, 2016, 35(5): 381 https://www.cnki.com.cn/Article/CJFDTOTAL-XJKB201605008.htm [45] Tam M D, Laycock S D, Bell D, et al. 3D printout of a DICOM file to aid surgical planning in a 6 year old patient with a large scapular osteochondroma complicating congenital diaphyseal aclasia. J Radiol Case Rep, 2012, 6(1): 31 [46] Waran V, Narayanan V, Karuppiah R, et al. Utility of multimaterial 3D printers in creating models with pathological entities to enhance the training experience of neurosurgeons. J Neurosurg, 2014, 120(2): 489 doi: 10.3171/2013.11.JNS131066 [47] Lan Q, Chen A, Zhang T, et al. Development of three-dimensional printed craniocerebral models for simulated neurosurgery. World Neurosurg, 2016, 91: 434 doi: 10.1016/j.wneu.2016.04.069 -

下载:

下载: