Effect of additive dosage on the structure and mechanical properties of silicon carbide prepared by reaction sintering

-

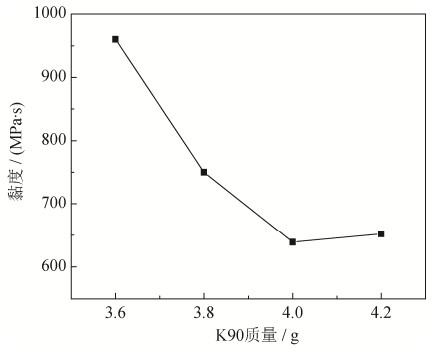

摘要: 以碳化硅、碳黑和石墨为原料, 聚乙烯吡咯烷酮K90、K30为分散剂, 聚甲基丙烯酸铵CE-64为减水剂, 采用注浆成型工艺制备碳化硅素坯, 并在1700℃下对素坯进行反应烧结制备碳化硅成品, 研究了分散剂、减水剂用量对浆料黏度、素坯密度、素坯孔隙率和成品微观组织及力学性能的影响。结果表明: 随着助剂用量的增加, 浆料黏度总体上呈现下降趋势, 素坯密度呈先降后升趋势, 素坯孔隙率呈先升后降趋势。当K90、K30、CE-64的质量分数分别为3.8%、2.0‰、4.3‰时, 所得素坯的孔隙分布均匀, 素坯中碳化硅分布较为疏松, 渗硅通道较多, 有利于碳和硅粉的充分反应, 获得的烧结制品性能优良。Abstract: The green silicon carbide was prepared by slip casting using silicon carbide, carbon black, and graphite as the raw materials, polyvinylpyrrolidone K90 and K30 as the dispersant, and ammonium methacrylate CE-64 as the superplasticizer. Subsequently, the final product of silicon carbide was subjected by reaction sintering at 1700℃. The influences of additive dosage on the slurry viscosity, green density, biscuit porosity, and the microstructure and mechanical performance of silicon carbide product were investigated. In the results, with the increase of additive dosage, the slurry viscosity shows a downward trend, the density of the green silicon carbide first decreases and then increases, and the porosity of the green silicon carbide first increases and then decreases. As the additive dosages of K90, K30, and CE-60 are 3.8%, 2.0‰, and 4.3‰ by mass, the pore distribution of the green is uniform, and the properties of the sintered products obtained are excellent. The loosen distribution of silicon carbide in the green offers more channels for silicon permeation, which is beneficial for the reaction between carbon and silicon.

-

Key words:

- silicon carbide /

- dispersant /

- superplasticizer /

- reaction sintering /

- mechanical properties

-

表 1 实验样品成分

Table 1. Composition of experimental samples

样品编号 F240 / g F1200 / g 碳黑/ g 石墨/ g K90 K30 CE-64 用量/ g 质量分数/ % 用量/ g 质量分数/ ‰ 用量/ g 质量分数/ ‰ A1 58 33 5 4 3.6 3.4 0.20 2.0 0.45 4.3 A2 58 33 5 4 3.8 3.6 0.20 2.0 0.45 4.3 A3 58 33 5 4 4.0 3.8 0.20 2.0 0.45 4.3 A4 58 33 5 4 4.2 4.0 0.20 2.0 0.45 4.3 B1 58 33 5 4 4.0 3.8 0.10 1.0 0.45 4.3 B2 58 33 5 4 4.0 3.8 0.15 1.4 0.45 4.3 B3 58 33 5 4 4.0 3.8 0.20 2.0 0.45 4.3 B4 58 33 5 4 4.0 3.8 0.25 2.4 0.45 4.3 C1 58 33 5 4 4.0 3.8 0.20 2.0 0.35 3.3 C2 58 33 5 4 4.0 3.8 0.20 2.0 0.40 3.8 C3 58 33 5 4 4.0 3.8 0.20 2.0 0.45 4.3 C4 58 33 5 4 4.0 3.8 0.20 2.0 0.50 4.8 -

[1] Wang Y X, Tan S H, Jiang D L. Research and development of reaction sintered silicon carbide. J Inorg Mater, 2004, 19(3): 456 doi: 10.3321/j.issn:1000-324X.2004.03.002王艳香, 谭寿洪, 江东亮. 反应烧结碳化硅的研究与进展. 无机材料学报, 2004, 19(3): 456 doi: 10.3321/j.issn:1000-324X.2004.03.002 [2] Wu Q D, Liu K S, Tu L, et al. Effects of molding methods on microstructure and strength of RBSC. J Ceram, 2011, 32(3): 407 doi: 10.3969/j.issn.1000-2278.2011.03.014武七德, 刘开松, 屠隆, 等. 成型方式对反应烧结碳化硅显微结构及强度的影响. 陶瓷学报, 2011, 32(3): 407 doi: 10.3969/j.issn.1000-2278.2011.03.014 [3] She J H, Jiang D L, Tan S H, et al. Improvement of SiC‒TiC composites by hot isostatic pressing. Powder Metall Technol, 1993, 11(1): 3 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ199301000.htm佘继红, 江东亮, 谭寿洪, 等. SiC‒TiC复相陶瓷的热等静压改性. 粉末冶金技术, 1993, 11(1): 3 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYJ199301000.htm [4] Hao B, Chen L J, Yang X. Study on preparation of reaction-sintered silicon carbude ceramic. Ceramics, 2008, 9(9): 13 doi: 10.3969/j.issn.1002-2872.2008.09.003郝斌, 陈立君, 杨霞. 反应烧结制备SiC陶瓷的研究进展. 陶瓷, 2008, 9(9): 13 doi: 10.3969/j.issn.1002-2872.2008.09.003 [5] Hao Y L, Zhao W X. Preparation and sintering mechanism of reaction-sintered silicon carbide ceramics. Refractories, 2000, 34(6): 313 doi: 10.3969/j.issn.1001-1935.2000.06.002郝寅雷, 赵文兴. 反应烧结碳化硅陶瓷的制备及烧结机理. 耐火材料, 2000, 34(6): 313 doi: 10.3969/j.issn.1001-1935.2000.06.002 [6] Liu H L. Study on Gel-Casting of Reaction-Bonded Silicon Carbide and Properties of Sintered Ceramics[Dissertation]. Beijing: China Building Materials Academy, 2004刘海林. 反应烧结碳化硅凝胶注模成型工艺及烧结体性能研究[学位论文]. 北京: 中国建筑材料科学研究总院, 2004 [7] Nie L F. Study on Properties of Reaction Sintered Silicon Carbide Formed by Gel-Casting Process[Dissertation]. Jinan: Shandong University, 2007聂丽芳. 凝胶注模成型反应烧结碳化硅制备工艺研究[学位论文]. 济南: 山东大学, 2007 [8] Wu H Y, Zhang G J, Wang W C. Effects of sintering temperature on microstructure and properties of reaction bonded silicon carbide. Powder Metall Technol, 2017, 35(5): 342 doi: 10.19591/j.cnki.cn11-1974/tf.2017.05.004巫红燕, 张国军, 王伟春. 烧结温度对反应烧结碳化硅组织与性能的影响. 粉末冶金技术, 2017, 35(5): 342 doi: 10.19591/j.cnki.cn11-1974/tf.2017.05.004 [9] Li S, Xie Z P, Zhang Y M, et al. Effect of carbon black on the microstructure and mechanical behaviors of reaction bonded silicon carbide ceramics reinforced by chopped fiber. Rare Met Mater Eng, 2015, 44(Suppl 1): 689 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE2015S1172.htm李双, 谢志鹏, 张宇民, 等. 炭黑含量对短纤维增强反应烧结碳化硅结构与性能的影响. 稀有金属材料与工程, 2015, 44(增刊1): 689 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE2015S1172.htm [10] Hua C S. Preparation of SiC Ceramic Materials by Reaction Melt Infiltration on Low Temperature and Study on Microstructure and Performance of the Materials[Dissertation]. Wuhan: Wuhan University of Technology, 2009华春松. 低温反应烧结制备碳化硅陶瓷材料及其结构与性能研究[学位论文]. 武汉: 武汉理工大学, 2009 [11] Zhang L, Zhang L, Zhang M, et al. Microstructure and properties of SiC ceramics fabricated by pressureless sintering at low-temperature. Trans Mater Heat Treat, 2015, 36(7): 7 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201507002.htm张龙, 张磊, 张明, 等. 低温常压烧结SiC陶瓷的结构与性能. 材料热处理学报, 2015, 36(7): 7 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201507002.htm [12] Vikan H, Justnes H, Winnefeld F, et al. Correlating cement characteristics with rheology of paste. Cem Concr Res, 2007, 37(11): 1502 doi: 10.1016/j.cemconres.2007.08.011 [13] Chandra S, Björnström J. Influence of superplasticizer type and dosage on the slump loss of Portland cement mortars-Part II. Cem Concr Res, 2002, 32(10): 1613 doi: 10.1016/S0008-8846(02)00838-4 [14] Xie W, Zheng Y Y, Kuang J C, et al. Study on preparation of spherical silver powders with polyvinylpyrrolidone as dispersant. Powder Metall Ind, 2015, 25(1): 23 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201501007.htm谢炜, 郑亚亚, 匡加才, 等. 以聚乙烯吡咯烷酮为分散剂制备球形银粉的研究. 粉末冶金工业, 2015, 25(1): 23 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201501007.htm [15] Li W, Gu M Y, Jin Y P. Effect of dispersant concentration on rheological behavior of SiC aqueous suspension. J Chin Ceram Soc, 2004, 32(11): 1356 doi: 10.3321/j.issn:0454-5648.2004.11.008李玮, 顾明元, 金燕萍. 分散剂用量对碳化硅浆料流变性能的影响. 硅酸盐学报, 2004, 32(11): 1356 doi: 10.3321/j.issn:0454-5648.2004.11.008 [16] Shi X M, Cui H, Cao J W, et al. The densification of SiC ceramics prepared by pressureless sintering. J Ceram, 2017, 38(1): 20 https://www.cnki.com.cn/Article/CJFDTOTAL-TCXB201701012.htm史秀梅, 崔红, 曹剑武, 等. SiC陶瓷常压烧结致密化过程的研究. 陶瓷学报, 2017, 38(1): 20 https://www.cnki.com.cn/Article/CJFDTOTAL-TCXB201701012.htm [17] Jiang H B, Shu C X, Liu J W, et al. Effect of SiC perform preparation process on structure and properties of reaction bonded silicon carbide. Powder Metall Ind, 2012, 22(6): 43 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201206016.htm蒋会宾, 束成祥, 刘君武, 等. 素坯制备工艺对反应烧结碳化硅结构与性能的影响. 粉末冶金工业, 2012, 22(6): 43 https://www.cnki.com.cn/Article/CJFDTOTAL-FMYG201206016.htm -

下载:

下载: