Effect of in-situ synthesized calcium hexaluminate on the structure and properties of porous corundum materials

-

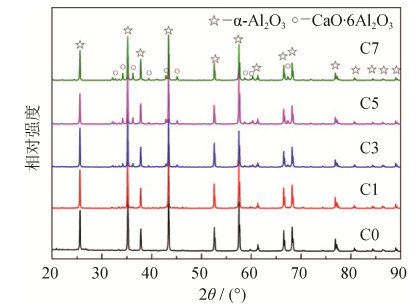

摘要: 为解决多孔透气材料力学强度与透气性能两者之间的矛盾, 以纯铝酸钙水泥为钙源, 在刚玉质多孔材料中原位生成六铝酸钙相, 研究了六铝酸钙生成量对多孔材料显微结构、物相组成及物理性能的影响。结果表明: 在1700℃保温3 h处理后, 添加纯铝酸钙水泥的试样中均有板状片六铝酸钙生成。当纯铝酸钙水泥添加量(质量分数)不超过3%时, 六铝酸钙的原位生成不仅提高了多孔材料的常温耐压强度和高温抗折强度(1400℃保温0.5 h), 还能改善材料的透气性能; 继续增加纯铝酸钙水泥的加入量, 多孔材料的上述性能降低。当纯铝酸钙水泥添加量(质量分数)为3%时, 试样常温耐压强度为33.6 MPa, 高温抗折强度为6.2 MPa, 达西渗流系数及非达西渗流系数分别为2.54×10-10 m2和1.46×10-6 m。Abstract: To balance the contradiction of mechanical strength and air permeability of porous corundum materials, the calcium hexaluminate was in-situ synthesized in the porous materials by using pure calcium aluminate cement as the calcium source. The effects of in-situ synthesized calcium hexaluminate on the microstructure, phase composition, and mechanical properties of the porous corundum materials were investigated. The results show that, the plate-like calcium hexaluminate particles can be in-situ synthesized in the specimens added with pure calcium aluminate cement after treated at 1700 for 3 h. When the mass fraction of pure calcium℃aluminate cement is no more than 3%, the in-situ synthesized calcium hexaluminate not only improves the cold compressive strength and the high-temperature bending strength (1400℃×0.5 h) of the porous material, but also improves the air permeability of specimens. With further increase of pure calcium aluminate cement additions, the above properties of the specimens turn to a reversed trend. The cold compressive strength of specimen added with 3% pure calcium aluminate cement by mass is 33.6 MPa, the highest high-temperature bending strength is 6.2 MPa, and the Darcian permeability and non-Darcian permeability constant are 2.54×10-10 m2and 1.46×10-6 m, respectively.

-

Key words:

- porous materials /

- in-situ synthesis /

- calcium hexaluminate /

- mechanical strength /

- air permeability

-

表 1 烧成试样的物理性能

Table 1. Physical properties of the sintering specimens

试样编号 线变化率/ % 体积密度/ (g·cm-3) 显气孔率/ % 耐压强度/ MPa 高温抗折强度/ MPa C0 -0.43 ± 0.03 2.74 ± 0.01 27.8 ± 0.1 32.1 ± 1.1 5.8 ± 0.3 C1 -0.36 ± 0.02 2.74 ± 0.02 27.1 ± 0.2 34.0 ± 0.7 6.0 ± 0.2 C3 -0.31 ± 0.03 2.71 ± 0.02 27.5 ± 0.2 33.6 ± 0.6 6.2 ± 0.2 C5 -0.19 ± 0.02 2.69 ± 0.01 27.8 ± 0.1 24.5 ± 1.5 5.8 ± 0.3 C7 -0.05 ± 0.01 2.67 ± 0.02 28.4 ± 0.3 22.8 ± 2.0 5.4 ± 0.5 图 3(b)能谱选区 原子数分数/ % Al O Ca 1 39.12 57.73 3.15 2 39.94 58.76 1.31 3 39.98 60.02 — 表 3 渗流曲线基于Forchheimer’s方程的拟合结果

Table 3. Polynomial fitting results of Forchheimer's equation

试样编号 k1 / (×10-10m2) k2 / (×10-6m) R2 C0 2.27 1.41 0.9998 C1 2.40 1.42 0.9998 C3 2.54 1.46 0.9998 C5 2.51 1.45 0.9999 C7 2.23 1.40 0.9998 -

[1] Huang A, Fu L P, Gu H Z, et al. Towards slag-resistant, anti-clogging and chrome-free castable for gas purging. Ceram Int, 2016, 42(16): 18674 doi: 10.1016/j.ceramint.2016.09.005 [2] Long B, Xu G Y, Andreas B. Microstructure and physical properties of steel-ladle purging plug refractory materials. Int J Miner Metall Mater, 2017, 24(2): 186 doi: 10.1007/s12613-017-1394-5 [3] Li Y B, Xiang D C, Li N. Current status and development of permeable-gas ceramics used in refining of aluminum melt. Refractories, 2005, 39(4): 292 doi: 10.3969/j.issn.1001-1935.2005.04.016李远兵, 向德成, 李楠. 铝熔体精炼用透气陶瓷的研究现状. 耐火材料, 2005, 39(4): 292 doi: 10.3969/j.issn.1001-1935.2005.04.016 [4] Chen G, Yuan H B, Lü Z H. Application of nitrogen bottom-blowing porous brick in copper anode furnace. Nonferrous Met Extr Metall, 2015(3): 16 doi: 10.3969/j.issn.1007-7545.2015.03.005陈钢, 袁海滨, 吕忠华. 氮气底吹透气砖在铜阳极炉上的应用. 有色金属(冶炼部分), 2015(3): 16 doi: 10.3969/j.issn.1007-7545.2015.03.005 [5] Chang Y N, Zhang L, Shao Z M. Research and development direction of purging plug for ladle. J Univ Sci Technol Liaoning, 2016, 39(3): 191 https://www.cnki.com.cn/Article/CJFDTOTAL-ASGT201603005.htm常雅楠, 张玲, 邵子铭. 钢包用透气砖的研究与发展方向. 辽宁科技大学学报, 2016, 39(3): 191 https://www.cnki.com.cn/Article/CJFDTOTAL-ASGT201603005.htm [6] Li Y Q. Calcium-Dialuminate/Calcium-Hexaluminate/Corundum Composite Refractories[Dissertation]. Wuhan: Wuhan University of Science and Technology, 2004李有奇. CA2/CA6/刚玉复相耐火材料研究[学位论文]. 武汉: 武汉科技大学, 2004 [7] Tomba Martinez A G, Luz A P, Braulio M A L, et al. Revisiting CA6 formation in cement-bonded alumina-spinel refractory castables. J Eur Ceram Soc, 2017, 37: 5023 doi: 10.1016/j.jeurceramsoc.2017.07.003 [8] Luz A P, Consoni L B, Pagliosa C, et al. Sintering effect of calcium carbonate in high-alumina refractory castables. Ceram Int, 2018, 44(9): 10486 doi: 10.1016/j.ceramint.2018.03.066 [9] Salomão R, Ferreira V L, de Oliveira I R, et al. Mechanism of pore generation in calcium hexaluminate (CA6) ceramics formed in situ from calcined alumina and calcium carbonate aggregates. J Eur Ceram Soc, 2016, 36(16): 4225 doi: 10.1016/j.jeurceramsoc.2016.05.026 [10] Luz A P, Gabriel A H G, Consoni L B, et al. Self-reinforced high-alumina refractory castables. Ceram Int, 2018, 44: 2364 doi: 10.1016/j.ceramint.2017.10.205 [11] Yin X L, Chen M, Wang N, et al. Improvement of densification and mechanical properties of MgAl2O4-CaAl4O7-CaAl12O19 composite by addition of MnO. Ceram Int, 2017, 43(5): 4706 doi: 10.1016/j.ceramint.2016.12.091 [12] Liu X Y, Yang D X, Huang Z H, et al. In-situ synthesis of porous calcium hexa-aluminate ceramics and growth mechanism of the plate-like grains. Ceram Int, 2015, 41(10): 14727 doi: 10.1016/j.ceramint.2015.07.197 [13] Xiong X, Wang Z F, Wang X T, et al. Correlations between pore structure parameters and gas permeability of corundum porous materials. J Am Ceram Soc, https://doi.org/10.1111/jace.16861 doi: 10.1111/jace.16861 [14] Innocentini M D M, Pardo A R F, Pandolfelli V C. Influence of air compressibility on the permeability evaluation of refractory castables. J Am Ceram Soc, 2000, 83(6): 1536 doi: 10.1111/j.1151-2916.2000.tb01426.x [15] Innocentini M D M, Pardo A R F, Pandolfelli V C, et al. Permeability of high-alumina refractory castables based on various hydraulic binders. J Am Ceram Soc, 2010, 85(6): 1517 doi: 10.1111/j.1151-2916.2002.tb00306.x [16] Scheffler M, Colombo P. Cellular Ceramics: Structure, Manufacturing, Properties and Applications. Weinheim: Wiley-VCH, 2005 -

下载:

下载: