Effects of HfN content on microstructure and mechanical properties of ZrB2-HfN ceramic materials

-

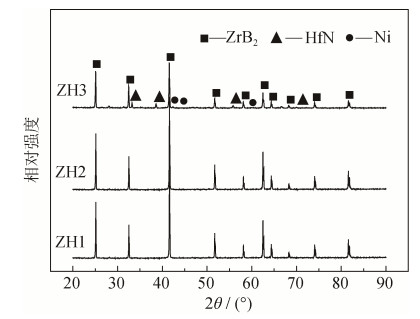

摘要: 以HfN为增强剂、Ni为金属添加剂, 通过真空热压烧结工艺制备了ZrB2-HfN陶瓷材料, 研究了HfN含量(质量分数)对ZrB2基陶瓷材料微观组织和力学性能的影响。结果表明: 随着HfN质量分数从5%增加到15%, ZrB2-HfN陶瓷材料的硬度和抗弯强度先增大后减小, 而断裂韧度逐渐增大; 当HfN质量分数为15%时, ZrB2-HfN陶瓷材料的断裂模式为穿晶断裂与沿晶断裂共存; 当HfN含量为10%时, ZrB2-HfN陶瓷材料具有较好的综合力学性能, 其硬度、抗弯强度和断裂韧度分别为: (16.47±0.24) GPa、(734.48±25) MPa和(5.37±0.20) MPa·m 1/2。Abstract: ZrB2 -HfN ceramic materials were fabricated by the vacuum hot-pressing sintering, and the influence of HfN content by mass on the microstructure and mechanical properties of the ZrB2 -HfN ceramic materials was studied. The results show that, with the HfN content by mass increasing from 5% to 15%, the Vickers hardness and flexural strength of the ZrB2 -HfN ceramic materials first increase and then decrease, while the fracture toughness increase gradually. When the content of HfN is 15%, the fracture mode ofZrB2 -HfN ceramic material is the coexistence of transgranular fracture and intergranular fracture. When the content of HfN is 10%, the ZrB2 -HfN ceramic material obtains the better mechanical properties, and the hardness, flexural strength, and fracture toughness are(16.47±0.24) GPa, (734.48±25) MPa, and (5.37±0.20) MPa·m 1/2, respectively.

-

图 2 ZrB2–HfN陶瓷材料的抛光面扫描电子显微形貌以及对应图 2(c)中不同位置的能谱分析图:(a)ZH1显微形貌;(b)ZH2显微形貌;(c)ZH3显微形貌;(d)图 2(c)A点能谱;(e)图 2(c)B点能谱;(f)图 2(c)C点能谱;

Figure 2. Surface SEM images of the ZrB2–HfN ceramic materials and the corresponding EDS: (a) ZH1 SEM image; (b) ZH2 SEM image; (c) ZH3 SEM image; (d) EDS of point A in Fig. 2(c); (e) EDS of point B in Fig. 2(c); (f) EDS of point C in Fig. 2(c)

表 1 ZrB2–HfN陶瓷材料的组分及配比(质量分数)

Table 1. Compositions of ZrB2–HfN ceramic materials

% 编号 ZrB2 HfN Ni ZH1 87 5 8 ZH2 82 10 8 ZH3 77 15 8 表 2 ZrB2–HfN陶瓷材料的相对密度和力学性能

Table 2. Relative densities and mechanical properties of ZrB2–HfN ceramic materials

编号 相对密度/ % 维氏硬度/ GPa 抗弯强度/ MPa 断裂韧度/ (MPa·m1/2) ZH1 99.4 ± 0.2 15.08 ± 0.20 422.96 ± 23 4.67 ± 0.22 ZH2 99.3 ± 0.1 16.47 ± 0.24 734.48 ± 25 5.37 ± 0.20 ZH3 99.1 ± 0.3 14.67 ± 0.23 540.46 ± 21 5.81 ± 0.15 -

[1] Song J G, Xu M H, Wang X Q, et al. Influence of YAG content on the properties of YAG-ZrB2 multi-phase ceramics. Powder Metall Technol, 2013, 31(5): 334 doi: 10.3969/j.issn.1001-3784.2013.05.003宋杰光, 徐明晗, 王秀琴, 等. YAG含量对ZrB2-YAG复相陶瓷的性能影响研究. 粉末冶金技术, 2013, 31(5): 334 doi: 10.3969/j.issn.1001-3784.2013.05.003 [2] Song J G, Wang F, Wang R H, et al. Influence of reinforced phase on properties of ZrB2 ceramic matrix composite. Powder Metall Technol, 2016, 34(4): 243 doi: 10.3969/j.issn.1001-3784.2016.04.001宋杰光, 王芳, 王瑞花, 等. 增强相对二硼化锆陶瓷基复合材料性能的影响. 粉末冶金技术, 2016, 34(4): 243 doi: 10.3969/j.issn.1001-3784.2016.04.001 [3] Mao X D, Bai L, Shen W P, et al. Preparation of ZrB2-SiC ceramic composites and testing of its resistance to thermal shock. Powder Metall Technol, 2008, 26(4): 260 http://pmt.ustb.edu.cn/article/id/fmyjjs200804004毛小东, 白玲, 沈卫平, 等. ZrB2-SiC复相陶瓷的制备及其耐热冲击性能的研究. 粉末冶金技术, 2008, 26(4): 260 http://pmt.ustb.edu.cn/article/id/fmyjjs200804004 [4] Chen L M, Suo X B, Wang A Z, et al. Thermal shock resistance and failure mechanism of ZrB2-based ultra-high temperature ceramic composites-a short review. J Chin Ceram Soc, 2018, 46(9): 1235 https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201809010.htm陈丽敏, 索相波, 王安哲, 等. ZrB2基超高温陶瓷材料抗热震性能及热震失效机制研究进展. 硅酸盐学报, 2018, 46(9): 1235 https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB201809010.htm [5] Guo Q L, Pei J J, Wang J, et al. Effects of the content of SiC on properties of ZrB2-SiC-Zr2Al4C5 composite ceramics. Rare Met Mater Eng, 2018, 47(Suppl 1): 282 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE2018S1062.htm郭启龙, 裴军军, 王璟, 等. SiC含量对ZrB2-SiC-Zr2Al4C5复相陶瓷性能的影响. 稀有金属材料与工程, 2018, 47(增刊1): 282 https://www.cnki.com.cn/Article/CJFDTOTAL-COSE2018S1062.htm [6] Wang M F, Wang C A, Zhang X H. Effects of SiC platelet and ZrSi2 additive on sintering and mechanical properties of ZrB2-based ceramics by hot-pressing. Mater Des, 2012, 34: 293 doi: 10.1016/j.matdes.2011.08.016 [7] Sonber J K, Murthy T S R Ch, Subramanian C, et al. Effect of CrSi2 and HfB2 addition on densification and properties of ZrB2. Int J Refract Met Hard Mater, 2012, 31: 125 doi: 10.1016/j.ijrmhm.2011.10.001 [8] Li Y J, Li J, Liu H L, et al. Oxidation behavior of ZrB2-SiBCN composite ceramics at constant temperature. J Synth Cryst, 2016, 45(9): 2295 doi: 10.3969/j.issn.1000-985X.2016.09.022李亚静, 李婧, 刘洪丽, 等. ZrB2-SiBCN复合陶瓷恒温氧化行为研究. 人工晶体学报, 2016, 45(9): 2295 doi: 10.3969/j.issn.1000-985X.2016.09.022 [9] Li Y Y, Li Q G, Wang Z, et al. Preparation of ZrB2-ZrC-SiC composite ceramic powder. J Univ Jinan Sci Technol, 2015, 29(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-SDJC201501001.htm栗媛媛, 李庆刚, 王志, 等. ZrB2-ZrC-SiC复合陶瓷粉体制备工艺. 济南大学学报(自然科学版), 2015, 29(1): 1 https://www.cnki.com.cn/Article/CJFDTOTAL-SDJC201501001.htm [10] An J, Song J P, Liang G X, et al. Effects of HfB2 and HfN additions on the microstructures and mechanical properties of TiB2-based ceramic tool materials. Materials, 2017, 10(5): 461 doi: 10.3390/ma10050461 [11] Song J P, Cao L, Gao J J, et al. Effects of HfN content and metallic additives on the microstructure and mechanical properties of TiC0.7N0.3-based ceramic tool materials. J Alloys Compd, 2018, 753: 85 doi: 10.1016/j.jallcom.2018.04.213 [12] Jing Y, Yuan H B, Lian Z S. Microstructure and mechanical properties of ZrB2-HfC ceramics influenced by HfC addition. Materials, 2018, 11: 2046 doi: 10.3390/ma11102046 [13] Monteverde F, Fabbriche D D, Bellosi A. Zirconium diboride-based composites. Key Eng Mater, 2002, 206: 961 https://www.sciencedirect.com/science/article/pii/S0263436818305869 [14] Yue X Y, Cai Z X, Lü X H, et al. Effect of Ni content on microstructures and mechanical properties of hot-pressed TiC-TiB2-Ni composite. Mater Sci Eng A, 2016, 668: 208 doi: 10.1016/j.msea.2016.05.053 [15] Mousavi M J, Zakeri M, Rahimipour M R, et al. Effect of Ni and C additives on pressureless sintering and mechanical properties of ZrB2. Adv Appl Ceram, 2015, 114(5): 261 doi: 10.1179/1743676114Y.0000000227 [16] Wang L M, Liu H L, Huang C Z, et al. Effects of sintering processes on mechanical properties and microstructure of Ti (C, N)-TiB2-Ni composite ceramic cutting tool material. Ceramic Int, 2014, 40(10): 16513 doi: 10.1016/j.ceramint.2014.08.003 [17] Song J P, Jiang L K, Liang G X, et al. Strengthening and toughening of TiN-based and TiB2-based ceramic tool materials with HfC additive. Ceramic Int, 2017, 43(11): 8202 doi: 10.1016/j.ceramint.2017.03.147 [18] Zhao G L, Huang C Z, Liu H L, et al. Microstructure and mechanical properties of TiB2-SiC ceramic composites by reactive hot pressing. Int J Refract Met Hard Mater, 2014, 42: 36 doi: 10.1016/j.ijrmhm.2013.10.007 [19] Gu M L, Huang C Z, Zou B, et al. Effect of (Ni, Mo) and TiN on the microstructure and mechanical properties of TiB2 ceramic tool materials. Mater Sci Eng A, 2006, 433: 39 doi: 10.1016/j.msea.2006.07.012 -

下载:

下载: