Study on the microstructure and properties of dispersion-reinforced Cu-based composites by ultrafine WC and nano-sized Al2O3 particles via extrusion densification

-

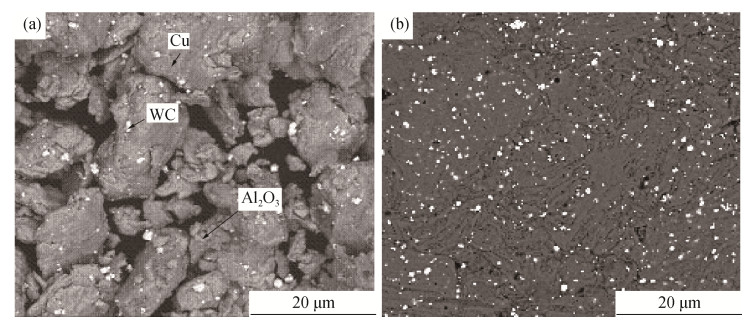

摘要: 以纳米Al2O3颗粒、超细WC粉末、工业纯Cu粉末为原料, 通过热挤压致密获得了超细WC/纳米Al2O3弥散强化铜基(WC-Al2O3/Cu)复合材料, 研究了挤压态WC-Al2O3/Cu复合材料的微观组织及力学性能。结果表明: 成分为5% WC-2% Al2O3/Cu和10% WC-2% Al2O3/Cu (质量分数)的两种原料粉末, 经机械球磨、冷压、真空烧结和热挤压后, 其相对密度均达到了99%以上, 超细WC和纳米Al2O3强化相颗粒呈均匀弥散分布, 具有很好的导电性及力学性能; 其中, 5% WC-2% Al2O3/Cu复合材料的综合性能更佳, 其抗拉强度达到235.06 MPa, 延伸率为15.47%, 导电率可达85.28% IACS, 软化温度不低于900℃。Abstract: The dispersion-reinforced Cu-based composites by ultrafine WC and nano-sized Al2O3 particles (WC-Al2O3/Cu)were obtained by hot extrusion densification using the nano-sized Al2O3 particles, ultrafine WC powders, and industrial pure copper powders as raw materials. The microstructures and performances of the extruded WC-Al2O3/Cu composites were investigated. In the results, the relative density of the 5%WC-2%Al2O3/Cu and 10%WC-2%Al2O3/Cu composites by mass is over99% after mechanical milling, cold pressing, vacuum sintering, and hot extrusion. At this meantime, the ultrafine WC and nano-sized Al2O3 particles distribute homogenously in the Cu matrix, resulting in high mechanical strength and excellent electrical conductivity. The tensile strength, elongation, and electrical conductivity of 5%WC-2%Al2O3/Cu composites are 235.06 MPa, 15.47%, and 85.28% IACS, respectively, and the softening temperature is above 900℃, showing a better comprehensive performances.

-

表 1 挤压态5%WC-2%Al2O3/Cu和10%WC-2%Al2O3/Cu复合材料的综合性能对比

Table 1. Comparison of the comprehensive property between the extruded 5%WC-2%Al2O3/Cu and 10%WC-2%Al2O3/Cu composites

材料 硬度,HV 相对密度/ % 抗拉强度/ MPa 延伸率/ % 软化温度/ ℃ 导电率/ (% IACS) 5%WC-2%Al2O3/Cu 153.7 99.53 235.06 15.47 > 900 85.28 10%WC-2%Al2O3/Cu 156.7 99.05 244.44 14.68 > 900 77.41 -

[1] Wang F, Chang Y H, Jia C C, et al. Preparation of Al2O3/Cu composite with high softening temperature by mechanical alloying and spark plasma sintering. Powder Metall Technol, 2016, 34(4): 285 doi: 10.3969/j.issn.1001-3784.2016.04.010王峰, 常宇宏, 贾成厂, 等. 机械合金化结合放电等离子烧结制备高软化温度Al2O3/Cu复合材料. 粉末冶金技术, 2016, 34(4): 285 doi: 10.3969/j.issn.1001-3784.2016.04.010 [2] Liu Y, Leng J F, Li Z W, et al. Processing and electrical properties of nano-Al2O3/Cu composites. Mater Sci Forum, 2017, 898: 984 doi: 10.4028/www.scientific.net/MSF.898.984 [3] Zhang Y F, Ji Z, Liu G M, et al. Manufacturing process and properties of Al2O3dispersion strengthened copper-based composite with high electrical conductivity. Powder Metall Technol, 2016, 34(5): 346 doi: 10.3969/j.issn.1001-3784.2016.05.005张一帆, 纪箴, 刘贵民, 等. Al2O3弥散增强Cu基高导电率复合材料的制备及性能研究. 粉末冶金技术, 2016, 34(5): 346 doi: 10.3969/j.issn.1001-3784.2016.05.005 [4] Li S L, Song K X, Guo X H. Study of Al2O3/Cu composite prepared by SPS. Powder Metall Technol, 2013, 31(1): 43 doi: 10.3969/j.issn.1001-3784.2013.01.009李韶林, 宋克兴, 国秀花. SPS法制备Al2O3/Cu复合材料研究. 粉末冶金技术, 2013, 31(1): 43 doi: 10.3969/j.issn.1001-3784.2013.01.009 [5] Liu J L, Wang E D, Liu Z Y, et al. Phases interface in deformation processed Cu-15wt% Cr composite prepared by elemental powders. Mater Sci Eng A, 2004, 382(1-2): 301 doi: 10.1016/j.msea.2004.04.074 [6] Hu L X, Wang X L, Wang E D. Fabrication of high strength conductivity submicroncrystalline Cu-5% Cr alloy by mechanical alloying. Trans Nonferrous Met Soc China, 2000, 10(2): 209 http://d.wanfangdata.com.cn/Periodical/zgysjsxb-e200002016 [7] He W X, Wang E D, Hu L X, et al. Effect of extrusion on microstructure and properties of a submicron crystalline Cu-5wt% Cr alloy. J Mater Process Technol, 2008, 208(1-3): 205 doi: 10.1016/j.jmatprotec.2007.12.107 [8] Botcharova E, Freudenberger J, Schultz L. Mechanical and electrical properties of mechanically alloyed nanocrystalline Cu‒Nb alloys. Acta Mater, 2006, 54(12): 3333 doi: 10.1016/j.actamat.2006.03.021 [9] Freudenberger J, Botcharova E, Schultz L. Formation of the microstructure in Cu‒Nb alloys. J Mater Sci, 2004, 39(16-17): 5343 [10] Liang S H, Xu L, Fang L, et al. Fabrication of internally oxidized powder for Al2O3/Cu composites. Powder Metall Technol, 2003, 21(4): 201 doi: 10.3321/j.issn:1001-3784.2003.04.002梁淑华, 徐磊, 方亮, 等. Al2O3/Cu复合材料内氧化粉末的制备. 粉末冶金技术, 2003, 21(4): 201 doi: 10.3321/j.issn:1001-3784.2003.04.002 [11] Liang S H, Fang L, Xu L, et al. Effect of Al content on the properties and microstructure of Al2O3‒Cu composite prepared by internal oxidation. J Compos Mater, 2004, 38(17): 1495 doi: 10.1177/0021998304043752 [12] Li J X, Hu R, Li J S, et al. Study on fine grains Al2O3/Cu composites. Powder Metall Technol, 2002, 20(5): 276 doi: 10.3321/j.issn:1001-3784.2002.05.004李进学, 胡锐, 李金山, 等. 细晶Al2O3/Cu复合材料的研究. 粉末冶金技术, 2002, 20(5): 276 doi: 10.3321/j.issn:1001-3784.2002.05.004 [13] Zhao N Q, Zhou F G, Chen M F, et al. The microstructure and sintering process of P/M WC reinforced copper composite. Powder Metall Technol, 2002, 18(4): 265 doi: 10.3321/j.issn:1001-3784.2000.04.006赵乃勤, 周复刚, 陈民芳, 等. WC/Cu复合材料组织及烧结过程研究. 粉末冶金技术, 2002, 18(4): 265 doi: 10.3321/j.issn:1001-3784.2000.04.006 [14] Zhang S L, Song K X, Guo X H, et al. Effect of mixing TiB2particles on microstructure and properties of TiB2/Cu composites. Trans Mater Heat Treat, 2018, 39(8): 7 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201808002.htm张胜利, 宋克兴, 国秀花, 等. TiB2颗粒混杂对TiB2/Cu复合材料微观组织和性能的影响. 材料热处理学报, 2018, 39(8): 7 https://www.cnki.com.cn/Article/CJFDTOTAL-JSCL201808002.htm [15] Lu K. The future of metals. Science, 2010, 328(5976): 319 doi: 10.1126/science.1185866 -

下载:

下载: