-

摘要: 使用三维震动高能球磨机对选矿后的锰方硼石粉末进行球磨, 球磨时间设定为30、40及50 min, 采用透射电子显微镜(transmission electron microscope, TEM)、扫描电子显微镜(scanning electron microscope, SEM)以及X射线衍射仪(X-raydiffraction, XRD)对球磨后锰方硼石粉末的形貌和结构进行表征, 利用Scherrer公式计算样品半高宽和晶粒尺寸, 并讨论球磨时间对锰方硼石发光特性的影响。结果表明, 锰方硼石经30、40、50 min高能球磨后, 样品粒径分别达到0.37、0.29、0.28 μm; 随球磨时间增加, 锰方硼石衍射峰明显宽化, (202)、(114)、(404)晶面的衍射峰强度明显降低, 晶面为不完全解理面; 锰方硼石样品发光强度随球磨时间增加明显降低。Abstract: The chambersite powders after mineral separation were prepared by 3D high-energy ball milling for 30, 40, and 50 min in this paper. Scanning electron microscope (SEM), transmission electron microscope (TEM), and X-ray diffraction (XRD) were utilized to characterize the microstructures of chambersite samples, and the Scherrer formula was used to calculate the half-height width and grain size of the samples. The luminescence properties of chambersite milled for different times were discussed. The results show that, the particle size of the chambersite samples after high-energy ball milling for 30, 40, and 50 min reaches 0.37, 0.29, and 0.28 μm, respectively. The diffraction peak of the chambersite samples is broadened with the increase of milling time, and the diffraction intensity of (202), (114), and (404) crystal faces decreases with the increases of milling time, noting the (202), (114), and (404) crystal faces are the incomplete cleavage planes. The luminescence intensity of the chamber site samples decreases remarkably with the increase of milling time.

-

Key words:

- chambersite /

- high-energy ball milling /

- microstructure /

- luminescent properties

-

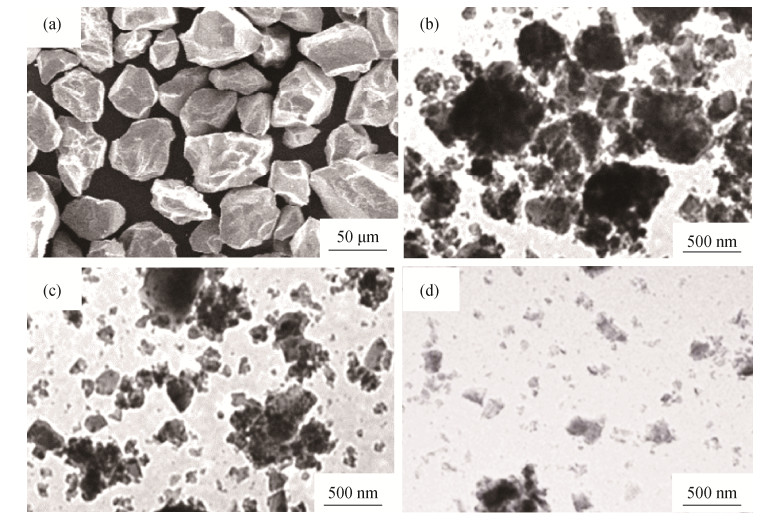

图 1 锰方硼石选矿后原始粉末扫描电子显微形貌和经高能球磨后透射电子显微形貌:(a)原始粉末扫描电子显微形貌;(b)球磨30 min透射电子显微形貌;(c)球磨40 min透射电子显微形貌;(d)球磨50 min透射电子显微形貌

Figure 1. Mcrostructures of chambersite powders after mineral separation and high-energy ball milling: (a) SEM image of raw powders; (b) TEM image of powders milled for 30 min; (c) TEM image of powders milled for 40 min; (d) TEM image of powders milled for 50 min

-

[1] Grice J D, Burns P C, Hawthorne F C, et al. Borate minerals. II. A hierarchy of structures based upon the borate fundamental building block. Can Mineral, 1999, 37(3): 731 https://pubs.geoscienceworld.org/canmin/article-abstract/37/3/731/13143/borate-minerals-ii-a-hierarchy-of-structures-based [2] Luce J L, Schaffers K I, Keszler D A, et al. Structure of the borate Li14Be5B (BO3)9. Inorg Chem, 2002, 33(11): 2453 http://www.researchgate.net/publication/231340219_Structure_of_the_borate_Li14Be5BBO39 [3] Liu Y F, Yang Z P, Yu Q M, et al. Luminescence properties of Ba2LiB5O10: Dy3+ phosphor. Mater Lett, 2011, 65(12), 1956 doi: 10.1016/j.matlet.2011.04.002 [4] Chen C, Bowen D T, Giagounidis A A, et al. Identification of disease-and therapy-associated proteome changes in the sera of patients with myelodysplastic syndromes and del (5q). Leukemia, 2010, 24(11): 1875 doi: 10.1038/leu.2010.182 [5] Prokhorov А A, Chernush L F, Minyakaev R, et al. Structural and magnetic properties of YAl3(BO3)4 and EuAl3(BO3)4 single crystals doped with Co2+. J Alloys Compd, 2018, 765: 710 doi: 10.1016/j.jallcom.2018.06.149 [6] Lü X S, Wei L, Wang X P, et al. Crystal growth, electronic structure and optical properties of Sr2Mg (BO3)2. J Solid State Chem, 2018, 258: 283 doi: 10.1016/j.jssc.2017.10.032 [7] Frolov K V, Lyubutin I S, Alekseeva O A, et al. Dynamics of structural and magnetic phase transitions in ferroborate YFe3(BO3)4. J Alloys Compd, 2018, 748: 989 doi: 10.1016/j.jallcom.2018.03.243 [8] Yu H, Deng D G, Su W T, et al. Broadband near-infrared downconversion luminescence in Yb3+-doped BaZn2(BO3)2. Opt Mater, 2018, 80: 160 doi: 10.1016/j.optmat.2018.04.035 [9] Cheng Z Y, Yu J J, Zhang Y J, et al. Luminescence and energy transfer mechanism of α-Ba3Y (BO3)3: Ce3+, Tb3+. J Lumin, 2017, 192: 1004 doi: 10.1016/j.jlumin.2017.08.041 [10] Xu R, Liang Y J, Liu S Q, et al. Structure and luminescence properties of Ce3+ doped KBa1−x(Mg/Zn)xY (BO3)2 and K1−yNayBaY (BO3)2 phosphors evolved from cation substitution. Opt Laser Technol, 2017, 93: 41 doi: 10.1016/j.optlastec.2017.01.027 [11] Wang Q S, Xu H, Gao S, et al. Synthesis of the rare mineral chambersite and its ore deposit geological significance. Earth Sci Front, 2013, 20(3): 123 https://www.cnki.com.cn/Article/CJFDTOTAL-DXQY201303016.htm王秋舒, 许虹, 高燊, 等. 稀有矿物锰方硼石的合成及其矿床地质意义. 地学前缘, 2013, 20(3): 123 https://www.cnki.com.cn/Article/CJFDTOTAL-DXQY201303016.htm [12] Liang D, Cao L, Jia C C, et al. Preparation and property of Mn3B7O13Cl microwave attenuation powders. Adv Mater Res, 2015, 1081: 156 http://www.researchgate.net/publication/273194640_Preparation_and_Property_of_Mn3B7O13Cl_Microwave_Attenuation_Powders [13] Xiong S, Liang D, Cao L, et al. Microstructure and luminescence characteristics of self-doped nano-Mn3B7O13Cl crystal. Mater Lett, 2016, 178: 87 doi: 10.1016/j.matlet.2016.04.196 [14] Gong L L, Cao L, Jia C C, et al. Friction properties of chambersite. J Univ Sci Technol Beijing, 2014, 36(3): 354 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201403012.htm龚立丽, 曹林, 贾成厂, 等. 锰方硼石的摩擦性能. 北京科技大学学报, 2014, 36(3): 354 https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201403012.htm [15] Gong L L, Cao L, Jia C C, et al. Effect of chambersite on friction and wear behavior of Cu-based friction material. Powder Metall Technol, 2013, 31(4): 279 doi: 10.3969/j.issn.1001-3784.2013.04.008龚立丽, 曹林, 贾成厂, 等. 锰方硼石对铜基摩擦材料摩擦性能的影响. 粉末冶金技术, 2013, 31(4): 279 doi: 10.3969/j.issn.1001-3784.2013.04.008 [16] Zhang Y F, Ji Z, Liu G M, et al. Manufacturing process and properties of Al2O3 dispersion strengthened copper-based composite with high electrical conductivity. Powder Metall Technol, 2016, 34(5): 346 doi: 10.3969/j.issn.1001-3784.2016.05.005张一帆, 纪箴, 刘贵民, 等. Al2O3弥散增强Cu基高导电率复合材料的制备及性能研究. 粉末冶金技术, 2016, 34(5): 346 doi: 10.3969/j.issn.1001-3784.2016.05.005 [17] Borc J, Sangwal K. On the perfection of cleavage planes of potassium bichromate single crystals. Surf Sci, 2007, 601(4): 1160 doi: 10.1016/j.susc.2006.12.033 [18] Yanagimoto F, Shibanuma K, Suzuki K, et al. Local stress in the vicinity of the propagating cleavage crack tip in ferritic steel. Mater Des, 2018, 144: 361 doi: 10.1016/j.matdes.2018.02.037 [19] Xu Z, Gu W B, Feng H, et al. Enhancement of structure stability and luminescence intensity of LiYF4: Ln3+ nanocrystals. J Rare Earths, 2017, 35(9): 844 doi: 10.1016/S1002-0721(17)60985-2 [20] Santos H D A, Novais S M V, Jacinto C, et al. Optimizing the Nd: YF3 phosphor by impurities control in the synthesis procedure. J Lumin, 2018, 201: 156 doi: 10.1016/j.jlumin.2018.04.051 -

下载:

下载: