Property characterization of Mn-Si powder porous alloy for semiconductors prepared by solid phase sintering

-

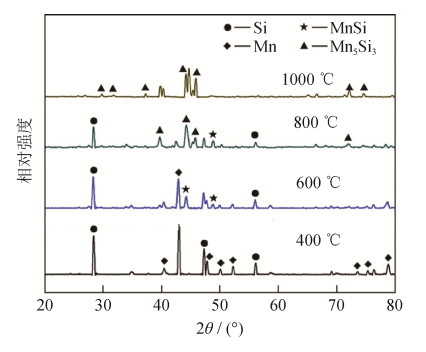

摘要: 以高纯Si粉和Mn粉为原料, 利用固相烧结技术制备得到Mn-Si粉末多孔合金, 对其组织结构及性能进行表征, 分析烧结过程中孔隙形成机理。结果表明: 600℃烧结温度可得到MnSi粉末, 烧结温度升高到1000℃后, 原有的Si与MnSi衍射峰已全部消失, 烧结体中只剩下Mn5Si3物相成分; 烧结体膨胀率和孔隙率都随烧结温度的增加表现出先增加后减小的变化规律, 在烧结温度800℃时取得最大值, 分别为8.86%和54.26%;在Mn颗粒和MnSi相之间存在明显空隙, 随着Si与Mn元素之间扩散的继续, 空隙持续增大进而连通形成层状, 随着烧结温度增加到1000℃, Mn、Si、MnSi被消耗殆尽, 合金中形成Mn5Si3结构。Abstract: The Mn-Si powder porous alloys were prepared by solid phase sintering, using high purity Si powders and Mn powders as the raw materials. The microstructure and properties of Mn-Si powder porous alloys were characterized and the for mation mechanism of pores in sintering process was analyzed. The results show that, the MnSi powders can be obtained at 600℃, with the increase of sintering temperature to 1000℃, the original diffraction peaks of Si and MnSi disappear, only Mn5Si3 phase is present inthe sintered body. The expansion ratio and porosity of the sintered body first increase and then decrease with the increase of sintering temperature, and show the maximum values (8.86% and 54.26%) at 800.℃ There is an obvious gap between Mn particles and MnSiphase, as the diffusion between Si and Mn continues, the gaps increase and then connect to form the lamellar structure; as the sintering temperature rises to 1000, Mn, Si, ℃ and MnSi is used up, the Mn5Si3 structure is formed.

-

Key words:

- solid phase sintering /

- porous alloy /

- microstructure /

- property characterization

-

表 1 不同烧结温度下Mn–Si粉末多孔合金的膨胀率和孔隙率

Table 1. Expansion ratio and porosity of Mn–Si powder porous alloy at different sintering temperatures

烧结温度/ ℃ 膨胀率/ % 孔隙率/ % 400 0.62 33.25 600 2.84 38.46 800 8.86 54.26 1000 5.66 51.08 表 2 不同烧结温度下Mn–Si粉末多孔合金的孔径

Table 2. Pore diameters of Mn–Si powder porous alloy at different sintering temperatures

烧结温度/ ℃ 平均孔径/ μm 最大孔径/ μm 400 6.12 11.62 600 5.86 10.86 800 6.84 12.74 1000 10.26 13.85 -

[1] Li T T, Peng C Q, Wang R C, et al. Research progress in porous Fe-Al, Ti-Al and Ni-Al intermetallic compound porous materials. Chin J Nonferrous Met, 2011, 21(4): 784 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201104013.htm李婷婷, 彭超群, 王日初, 等. Fe-Al、Ti-Al和Ni-Al系金属间化合物多孔材料的研究进展. 中国有色金属学报, 2011, 21(4): 784 https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201104013.htm [2] He Y H, Jiang Y, Xu N P, et al. Fabrication of Ti-Al micro/nanometer-sized porous alloys through the Kirkendall effect. Adv Mater, 2007, 19(16): 2102 doi: 10.1002/adma.200602398 [3] De Boor J, Kim D S, Ao X, et al. Temperature and structure size dependence of the thermal conductivity of porous silicon. Europhys Lett, 2011, 96(1): 16001 doi: 10.1209/0295-5075/96/16001 [4] Kanemitsu Y. Light emission from porous silicon and related materials. Phys Rep, 1995, 263(1): 1 doi: 10.1016/0370-1573(95)00021-4 [5] Ge M, Fang X, Rong J, et al. Review of porous silicon preparation and its application for lithium-ion battery anodes. Nanotechnolog, 2013, 24(42): 422001 doi: 10.1088/0957-4484/24/42/422001 [6] Anglin E J, Cheng L Y, Freeman W R, et al. Porous silicon in drug delivery devices and materials. Adv Drug Delivery Rev, 2008, 60(11): 1266 doi: 10.1016/j.addr.2008.03.017 [7] Dong H X, He Y H, Zou J, et al. Effect of preheating treatment at 575℃ of green compacts on porous NiAl. J Alloys Compd, 2010, 492(1-2): 219 doi: 10.1016/j.jallcom.2009.12.018 [8] Seitz F. On the porosity observed in the Kirkendall effect. Acta Metall, 1953, 1(3): 355 doi: 10.1016/0001-6160(53)90112-6 [9] Ni F, Fu L H, Deng P, et al. Effects of SiO2-B2O3-Al2O3 scaling powder on microstructures and properties of Cu-C-SnO2 porous materials sintered by powders. Powder Metall Technol, 2018, 36(5): 335 doi: 10.19591/j.cnki.cn11-1974/tf.2018.05.003倪锋, 傅丽华, 邓攀, 等. SiO2-B2O3-Al2O3助焊剂对粉末烧结Cu-C-SnO2多孔材料组织与性能的影响. 粉末冶金技术, 2018, 36(5): 335 doi: 10.19591/j.cnki.cn11-1974/tf.2018.05.003 [10] Yang J M, Tang Y, Gu H, et al. Research and application of 3D printed porous geometric structure: a review. Mater Rev, 2018, 32(15): 2672 doi: 10.11896/j.issn.1005-023X.2018.15.020杨建明, 汤阳, 顾海, 等. 3D打印制备多孔结构的研究与应用现状. 材料导报, 2018, 32(15): 2672 doi: 10.11896/j.issn.1005-023X.2018.15.020 [11] Zhao Y, Ren S B, Wang F L, et al. Preparation and properties of porous layer in copper based high flux heat transfer tube. Powder Metall Technol, 2018, 36(3): 170 doi: 10.19591/j.cnki.cn11-1974/tf.2018.03.002赵洋, 任淑彬, 王凤林, 等. 铜基高通量换热管内多孔层的制备及性能研究. 粉末冶金技术, 2018, 36(3): 170 doi: 10.19591/j.cnki.cn11-1974/tf.2018.03.002 [12] Zou Z H, Zeng F H, Liu J A, et al. Infiltration kinetics, microstructure and mechanical properties of B4C-MgSi composite fabricated by melt infiltration. Mater Sci Eng Powder Metall, 2018, 23(3): 252 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201803004.htm邹志欢, 曾凡浩, 刘吉安, 等. 熔渗制备B4C-MgSi复合材料的熔渗动力学、微观结构及力学性能. 粉末冶金材料科学与工程, 2018, 23(3): 252 https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201803004.htm [13] Zhang M L, Xie T F, Yang C P, et al. Effect of urea contents on pore structure and compressive properties of Ti-10% Mg porous materials. Dev Appl Mater, 2018, 33(2): 79 https://www.cnki.com.cn/Article/CJFDTOTAL-CLKY201802014.htm张美丽, 解腾飞, 杨超普, 等. 尿素含量对Ti-10% Mg多孔材料孔隙结构和抗压性能的影响. 材料开发与应用, 2018, 33(2): 79 https://www.cnki.com.cn/Article/CJFDTOTAL-CLKY201802014.htm [14] Fu Z R, Wang X C, Jin Q L, et al. A review of the preparation techniques for porous amorphous alloys and their composite. Mater Rev, 2018, 32(2): 473 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201803019.htm付正容, 王修昌, 金青林, 等. 多孔非晶合金及其复合材料的制备技术研究进展. 材料导报, 2018, 32(2): 473 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB201803019.htm [15] Xie R, Huang F, Fang Q, et al. Preparing Fe-Mn-Si ternary alloy by melting-ball-milling two-step method. Battery Bimonthly, 2011, 41(3): 135 https://www.cnki.com.cn/Article/CJFDTOTAL-DACI201103004.htm谢锐, 黄峰, 方茜, 等. 熔炼-球磨二步法制备Fe-Mn-Si三元合金. 电池, 2011, 41(3): 135 https://www.cnki.com.cn/Article/CJFDTOTAL-DACI201103004.htm -

下载:

下载: