Research on powder metallurgy process for preparing aluminum matrix boron carbide composites

-

摘要: 本文归纳了粉末冶金法制备铝基碳化硼复合材料的制备工艺, 主要包含混料、压制、烧结、变形等工艺环节; 对铝基碳化硼复合材料主要性能及影响因素做了阐述, 重点整理了材料均匀性、相对密度、力学性能的研究情况; 总结了工程用铝基碳化硼材料的生产及使用情况, 分析几种常见铝基碳化硼产品的特点; 提出采用粉末冶金法生产大尺寸、高品质、低成本的铝基碳化硼材料是未来研究方向之一的观点, 并阐述了工艺优化方案。在核电等相关产业的带动下, 中国有望成为全球铝基碳化硼复合材料生产和研究中心。Abstract: The preparation processes of aluminum matrix boron carbide composites made by powder metallurgy are summarized, those mainly include mixing, pressing, sintering, deformation, et al. The main performance of Al-B4C composites and its in fluence factors are introduced. The uniformity, relative density and mechanical properties of the material are studied. The production and application of Al-B4C composites are also introduced. The characteristics of several types of Al-B4C composites are described. The process optimization scheme is set forth to produce large size, high quality and low cost Al-B4C composites by powder metallurgy.China is expected to become one of the production and research centers of Al-B4C composites, with the development of nuclear power and other related industries.

-

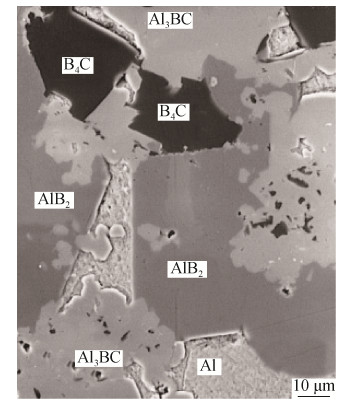

图 6 Al‒31%B4C板材金相照片[11]

Figure 6. Metallograph of Al‒31%B4C flats

表 1 含不同质量分数B4C的复合材料密度[11, 15‒16]

Table 1. Density of Al-B4C composite with different mass fraction of B4C[11, 15‒16]

材料 B4C质量分数/ % 工艺 密度,ρ / (g·cm-3) 相对密度/ % 理论值,ρ理 测量值,ρ测 铝基碳化硼复合材料 10 ① 2.681 2.624 97.8 20 2.662 2.596 97.5 30 2.643 2.582 97.4 40 2.592 2.520 97.2 30 ② 2.643 2.640 99.87 31 ③ 2.641 2.638 99.9 注:工艺①为热压(500~620 ℃)+ 轧制+ T6;工艺②为热压(530 ℃)+ T6;工艺③为热等静压工艺 材料 B4C质量分数/ % 工艺 抗拉强度/ MPa 屈服强度/ MPa 断后延伸率/

%6061Al 0 ① 310 270 15.0 6061Al‒B4C 10 ① 295 250 8.8 6061Al‒B4C 20 ① 271 224 4.0 6061Al‒B4C 30 ① 255 186 3.2 6061Al‒B4C 40 ① 232 163 2.0 包壳包覆Al‒B4C 30 ② 167 139 5.0 6061Al‒B4C 31 ③ 302 197 3.2 注:工艺①为热压(500~620 ℃)+ 轧制+ T6;工艺②为铝壳包覆+ 轧制;工艺③为热等静压(500 ℃ + 轧制) -

[1] Chen B M, Zhang Z Y, An L, et al. Research development of wear resistance of aluminum matrix composites under the condition of dry sliding friction. Powder Metall Technol, 2013, 31(6): 455 doi: 10.3969/j.issn.1001-3784.2013.06.011陈百明, 张振宇, 安亮, 等. 铝基金属复合材料在干摩擦条件下的抗磨损性能的研究进展. 粉末冶金技术, 2013, 31(6): 455 doi: 10.3969/j.issn.1001-3784.2013.06.011 [2] Alizadeh M. Comparison of nanostructured A1/B4C composite produced by ARB and Al/B4C composite produced by RRB process. Mater Sci Eng A, 2010, 528(2): 578 doi: 10.1016/j.msea.2010.08.093 [3] Tuncer N, Tasdelen B, Arslan G. Effect of passivation and precipitation hardening on processing and mechanical properties of B4C‒A1 composites. Ceram Int, 201l, 37(7): 2861 doi: 10.1016/j.ceramint.2011.05.007 [4] Carden R A, Calif C M. Fabrication Methods for Metal Matrix Composites: US Patent, 674166. 1996‒7‒1 [5] Arslan G, Kara F, Turan S. Quantitative X-ray diffraction analysis of reactive infiltrated boron carbide-aluminum composites. J Eur Ceram Soc, 2003, 23(8): 1243 doi: 10.1016/S0955-2219(02)00304-7 [6] Topcu I, Gulsoy H O, Kadioglu N, et al. Processing and mechanical properties of B4C reinforced Al matrix composites. J Alloys Compd, 2009, 482(1-2): 516 doi: 10.1016/j.jallcom.2009.04.065 [7] Khakbiz M, Akhlaghi F. Synthesis and structural characterization of Al‒B4C nano-composite powders by mechanical alloying. J Alloys Compd, 2009, 479(1-2): 334 doi: 10.1016/j.jallcom.2008.12.076 [8] Viala J C, Boulx J, Gonzalez G, et al. Chemical reactivity of aluminum with boron carbide. J Mater Sci, 1997, 32(17): 4559 doi: 10.1023/A:1018625402103 [9] Peng K W, Wu W Y, Xu J Y, et al. Study of chemical reaction and phase composition of B4C and Al under high temperature. Rare Met Cem Carbides, 2008, 36(1): 16 doi: 10.3969/j.issn.1004-0536.2008.01.004彭可武, 吴文远, 徐璟玉, 等. B4C和Al在高温条件下的化学反应及相组成的研究. 稀有金属与硬质合金, 2008, 36(1): 16 doi: 10.3969/j.issn.1004-0536.2008.01.004 [10] Zhang P, Zhang Z W, Li Y L, et al. Microstructure and mechanical properties of high content B4C-aluminium composites fabricated by hot-pressing sintering. Mater Sci Eng Powder Metall, 2014, 19(1): 95 doi: 10.3969/j.issn.1673-0224.2014.01.016张鹏, 张哲维, 李宇力, 等. 热压法制备高含量B4C/铝基复合材料的显微结构和力学性能. 粉末冶金材料科学与工程, 2014, 19(1): 95 doi: 10.3969/j.issn.1673-0224.2014.01.016 [11] Wang T J, Liu G H, Liu G R, et al. A Method for Preparing Neutron Absorber Plate by Hot Isostatic Pressure Welding: China Patent, 201510515626.0. 2015‒08‒20王铁军, 刘国辉, 刘桂荣, 等. 一种利用热等静压焊接工艺制备中子吸收板的方法: 中国专利, 201510515626.0. 2015‒08‒20 [12] Li Y L, Zhang P, Gao Z P, et al. Effect of B4C particle size on strength of B4C/6061Al compositions. Mater Sci Eng Powder Metall, 2012, 17(5): 611 doi: 10.3969/j.issn.1673-0224.2012.05.011李宇力, 张鹏, 高占平, 等. B4C颗粒增强相粒度对铝基体复合板材强度的影响. 粉末冶金材料科学与工程, 2012, 17(5): 611 doi: 10.3969/j.issn.1673-0224.2012.05.011 [13] Shen C L, Shi J M, Zhang L, et al. Effect of ball milling technics on B4C‒Al composite performance. J Funct Mater, 2011, 42(Suppl 2): 365 https://www.cnki.com.cn/Article/CJFDTOTAL-GNCL2011S2044.htm沈春雷, 石建敏, 张玲, 等. 球磨工艺对B4C‒Al复合粉末性能的影响. 功能材料, 2011, 42(增刊2): 365 https://www.cnki.com.cn/Article/CJFDTOTAL-GNCL2011S2044.htm [14] Jian M, Fu D G, Wang M L, et al. Effect of extrusion process on microstructure of B4C/Al‒Si composites. Nucl Power Eng, 2012, 33(Suppl 2): 91 https://www.cnki.com.cn/Article/CJFDTOTAL-HDLG2012S2022.htm简敏, 付道贵, 王美玲, 等. 挤压工艺对B4C/Al‒Si复合材料微观组织的影响. 核动力工程, 2012, 33(增刊2): 91 https://www.cnki.com.cn/Article/CJFDTOTAL-HDLG2012S2022.htm [15] Yuan N, Mou H H, Ni D, et al. Mechanical properties of B4C/Al composites for neutron absorption fabricated by rapid hot-pressing. Mater Sci Eng Powder Metall, 2016, 21(4): 589 doi: 10.3969/j.issn.1673-0224.2016.04.012袁楠, 牟浩瀚, 倪狄, 等. 快速热压法制备B4C/Al中子吸收材料的力学性能. 粉末冶金材料科学与工程, 2016, 21(4): 589 doi: 10.3969/j.issn.1673-0224.2016.04.012 [16] Gao Z P, Wang W X, Li Y L, et al. Microstructure and mechanical behavior of B4C‒aluminium composite. Hot Working Technol, 2012, 41(20): 89 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201220026.htm高占平, 王文先, 李宇力, 等. B4C颗粒增强铝基复合材料微观形貌和力学行为分析. 热加工工艺, 2012, 41(20): 89 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201220026.htm [17] Li G, Wang M L. Tensile properties and fracture characteristics of B4C/Al neutron absorber materials. Hot Working Technol, 2012, 41(22): 129 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201222036.htm李刚, 王美玲. B4C/Al中子吸收材料的拉伸性能及断口特征. 热加工工艺, 2012, 41(22): 129 https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201222036.htm [18] Ji Q, Wang N, Luan Y J, et al. Research of high cycle fatigue behavior of boron carbide reinforced 2009 aluminum matrix composites. Synth Mater Aging Appl, 2016, 45(3): 62 doi: 10.3969/j.issn.1671-5381.2016.03.015纪强, 王娜, 栾运加, 等. B4C/2009Al复合材料的高周疲劳性能研究. 合成材料老化与应用, 2016, 45(3): 62 doi: 10.3969/j.issn.1671-5381.2016.03.015 [19] Tan G L, Lu K K, Shi L B. Introduction to boron‒aluminum material for spent-fuel storage racks and transport cask in LWR nuclear power plants. Mater Rep, 2014, 28(24): 466 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2014S2119.htm谭功理, 卢可可, 石立波. 轻水堆核电站乏燃料贮存格架及运输容器用硼铝材料介绍. 材料导报, 2014, 28(24): 466 https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB2014S2119.htm [20] Wierschke J B. Evaluation of Aluminum‒Boron Carbide Neutron Absorbing Materials for Interim Storage of Used Nuclear Fuel[Dissertation]. Ann Arbor: The University of Michigan, 2015 [21] Mohanty R M, Balasubramanianan K, Seshadri S K. Boron carbide-reinforced aluminum 1100 matrix composites: Fabrication and properties. Mater Sci Eng A, 2008, 498(2): 42 https://www.sciencedirect.com/science/article/abs/pii/S0921509308007181 [22] Kang P C, Cao Z W, Wu G H, et al. Phase identification of Al‒B4C ceramic composites synthesized by reaction hot-press sintering. Int J Refract Met Hard Mater, 2010, 28(2): 297 doi: 10.1016/j.ijrmhm.2009.11.004 [23] Wang X J, Ma N G, Jing H D, et al. Wettability of Al on B4C substrate. Mater Mech Eng, 2008, 32(5): 15 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC200805004.htm王希军, 马南钢, 丁华东, 等. 铝在B4C陶瓷上的润湿性. 机械工程材料, 2008, 32(5): 15 https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC200805004.htm [24] Zhang Z, Fortin K, Charette A, et al. Effect of titanium on microstructure and fluidity of Al-B4C composites. J Mater Sci, 2011, 46(9): 3176 doi: 10.1007/s10853-010-5201-1 [25] Electric Power Research Institute. Industry Spent Fuel Storage Handbook. California: Electric Power Research Institute, 2010 [26] Kim K, Chung S, Hong J. Performance evaluation of METAMIC neutron absorber in spent fuel storage rack. Nucl Eng Technol, 2018, 50(5): 788 doi: 10.1016/j.net.2018.01.017 -

下载:

下载: